Crushing apparatus

A crushing device and crushing technology, which is applied in transportation and packaging, solid separation, filtering, etc., can solve the problems of longer recovery time and oil pressure loss, so as to reduce fuel consumption, reduce oil pressure loss, and avoid unnecessary the effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0084] [1] Overall composition

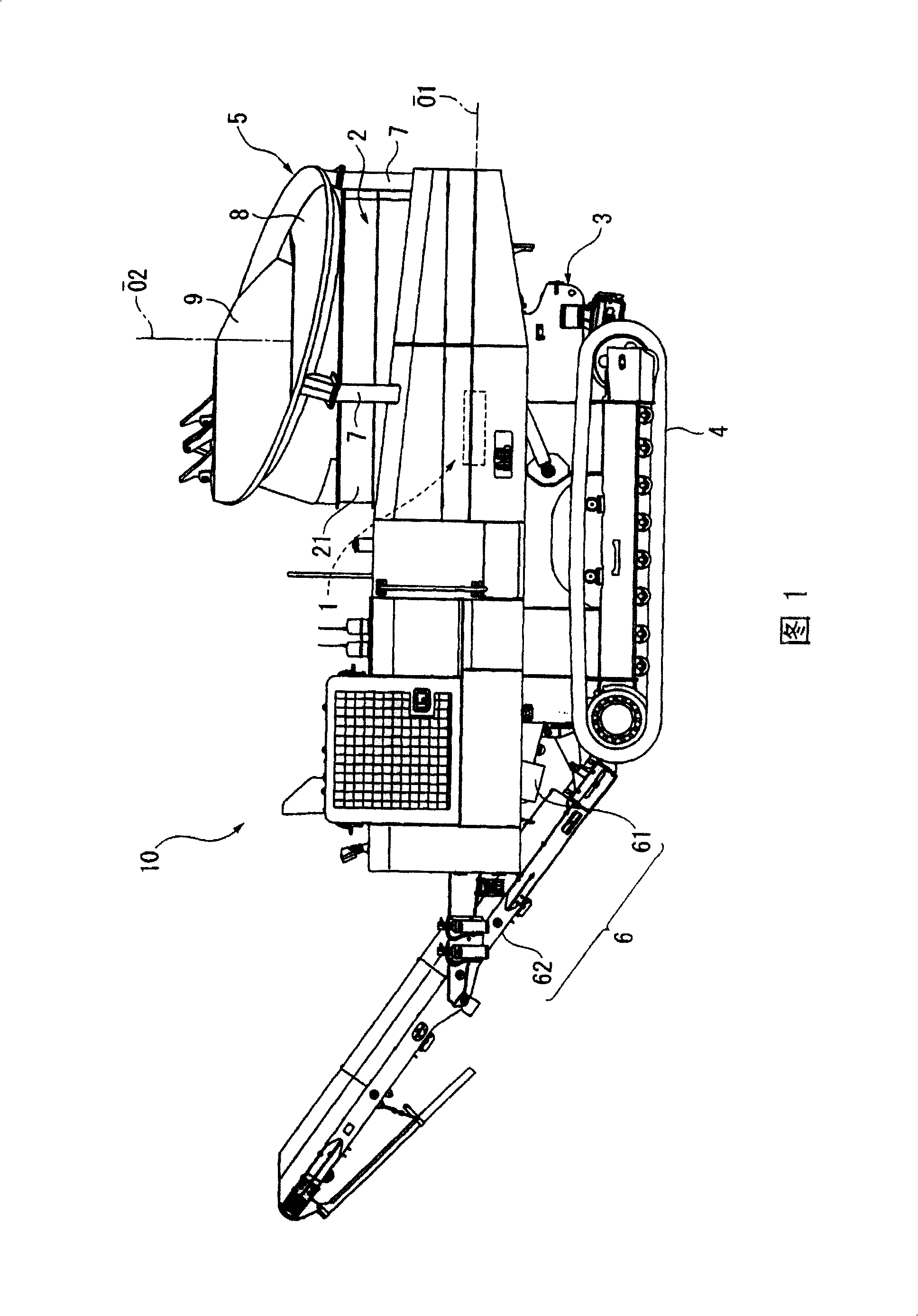

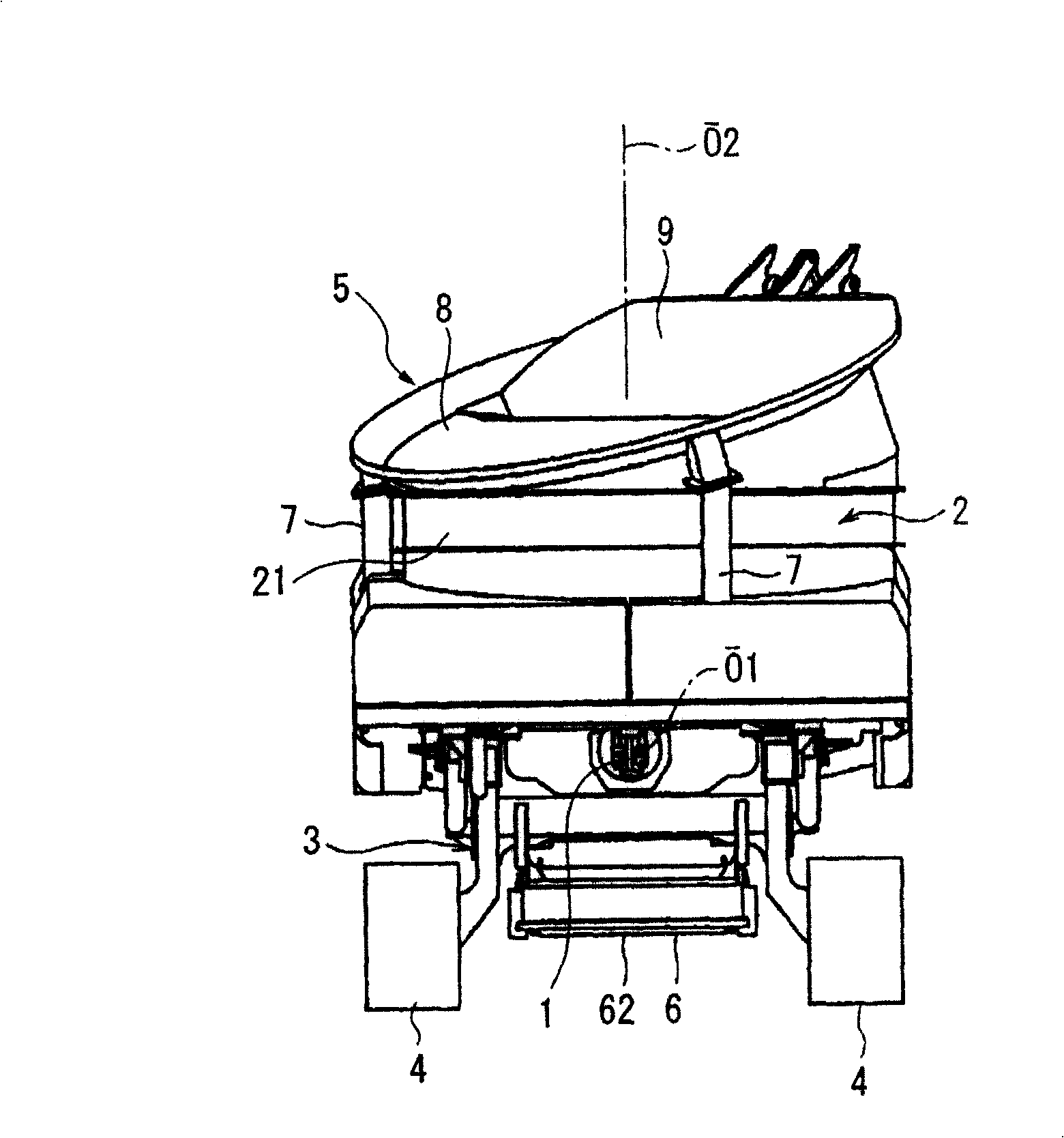

[0085] Next, specific embodiments of the crushing device of the present invention will be described in detail with reference to the accompanying drawings. Fig. 1 is a side view of the wood crushing device, figure 2 is its rear view.

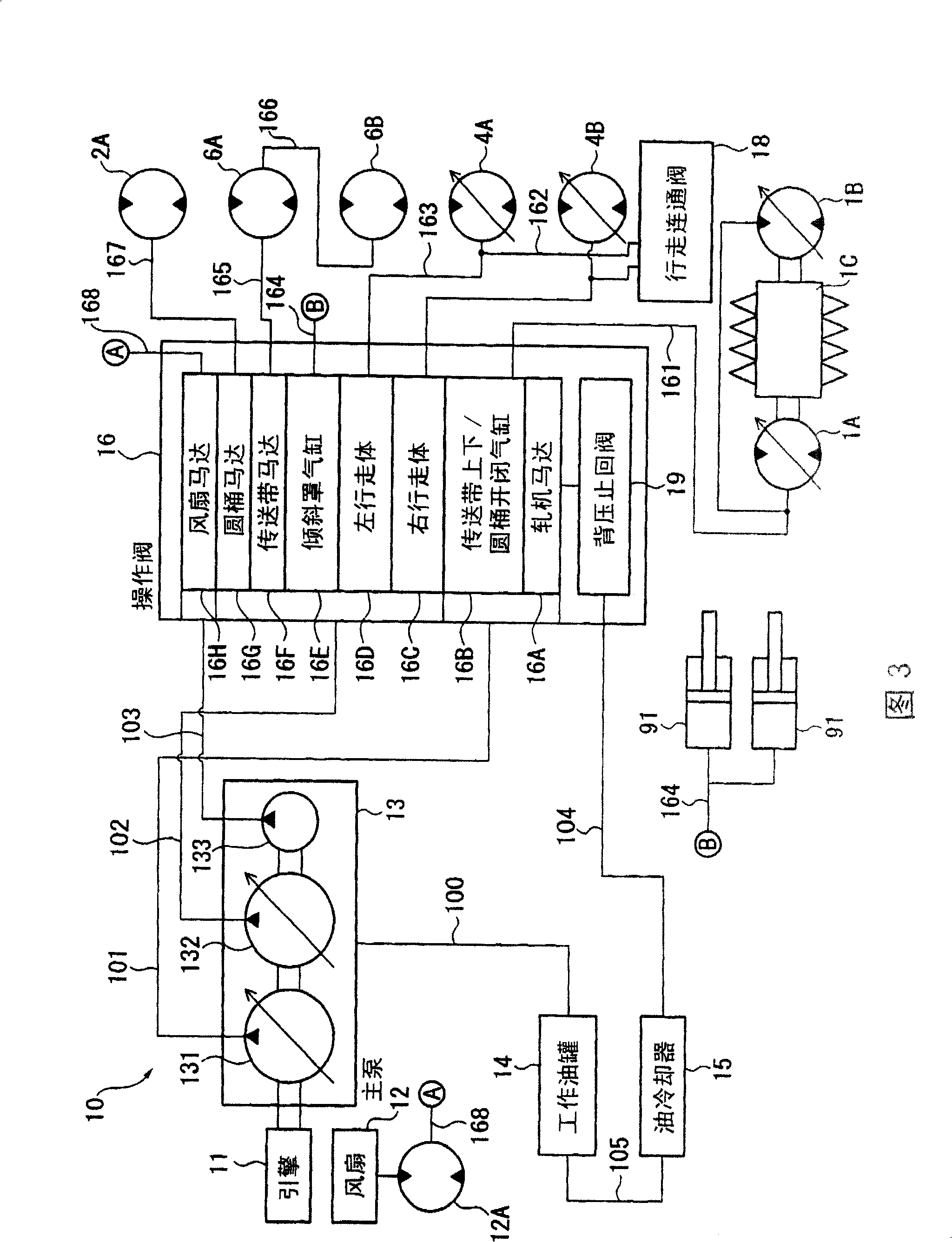

[0086] This wood shredder is self-propelled, and includes a shredder 1 and a substantially cylindrical drum (rotary drum) 2 that rotates around an axis O2 to supply wood to the shredder 1 .

[0087] In addition, a drum receiving frame for attaching the drum 2 around the axis, a crusher 1, etc. are attached to a chassis (machine body) 3, and a running body 4 is attached to the chassis 3. In addition, a hopper (fixed hopper) 5 is attached to the upper opening of the drum 2 , and wood is supplied into the drum 2 by putting wood into the hopper 5 .

[0088] Crusher 1 as shown in Figure 1 and figure 2 As shown, it includes a rotating shaft rotating around an axis O1 extending in the traveling direction of the woo...

Embodiment approach 2

[0236] Next, Embodiment 2 of the present invention will be described. In addition, in the following description, the description of the same parts as those already described will be omitted or simplified.

[0237] In the crushing device according to Embodiment 1 described above, the first hydraulic motor 1A is a variable displacement motor capable of changing displacement only by its own pressure.

[0238] In contrast, in the crushing device according to Embodiment 2, as shown in FIG. 13 , a solenoid 202 is connected to the first hydraulic motor 201A. It is set according to the change of capacity.

[0239] When the operator sets the capacity setting switch of the first hydraulic motor 201A on the operation panel to ON, the first hydraulic motor 201A is set to the small capacity side by the solenoid 202, and when the capacity setting switch is set to When off, it is set to the large capacity side. Moreover, the switching of the capacity of the first hydraulic motor 201A acco...

Embodiment approach 3

[0246] Next, Embodiment 3 of the present invention will be described.

[0247] In the above-described second embodiment, the solenoid 202 provided on the first hydraulic motor 201A is provided for the operator to set the capacity of the first hydraulic motor 201A.

[0248] In contrast, in the crushing device according to Embodiment 3, as shown in FIG. 15 , the first hydraulic motor 301A is not a motor of the type that uses its own pressure to switch the capacity, but a motor that uses an attached solenoid. The 302 type of excitation to switch the capacity of the motor is different in this point.

[0249] As the trigger sensor for switching the capacity of the first hydraulic motor 301A by the solenoid 302, in this embodiment, the pressure sensor 303 is used in the pump line 161A, and the output of the pressure sensor 303 is controlled by the controller 30. process to energize the solenoid 302 .

[0250] The control structure in the controller 30 is like the functional block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com