Vane for vertical shaft wind-driven generator and its making process

A wind turbine and vertical axis technology, which is applied to wind turbine components, wind turbines, wind turbines at right angles to the wind direction, etc., can solve the problems of huge processing equipment and expensive production costs, and achieve clear and lightening of structural stress. Weight, the effect of realizing large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

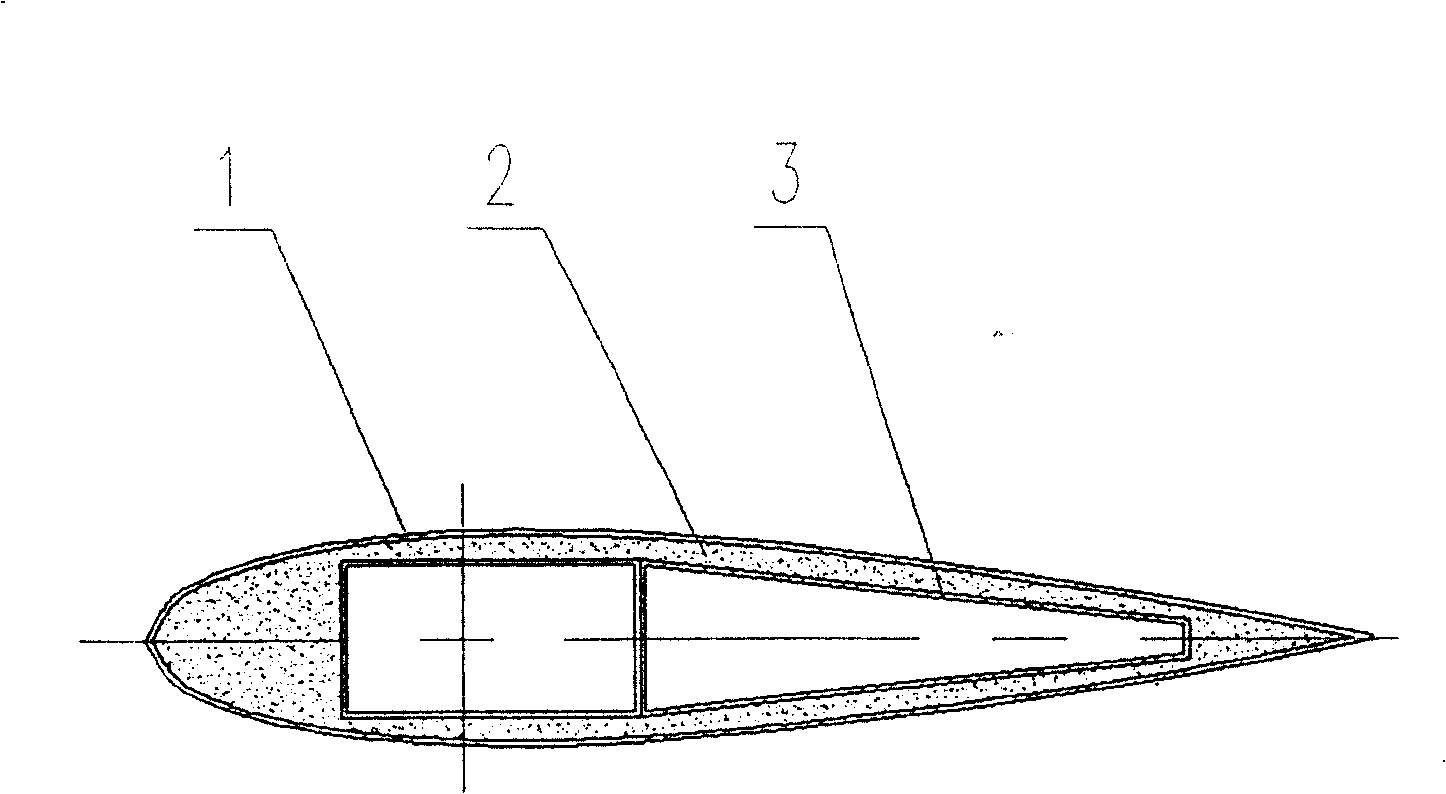

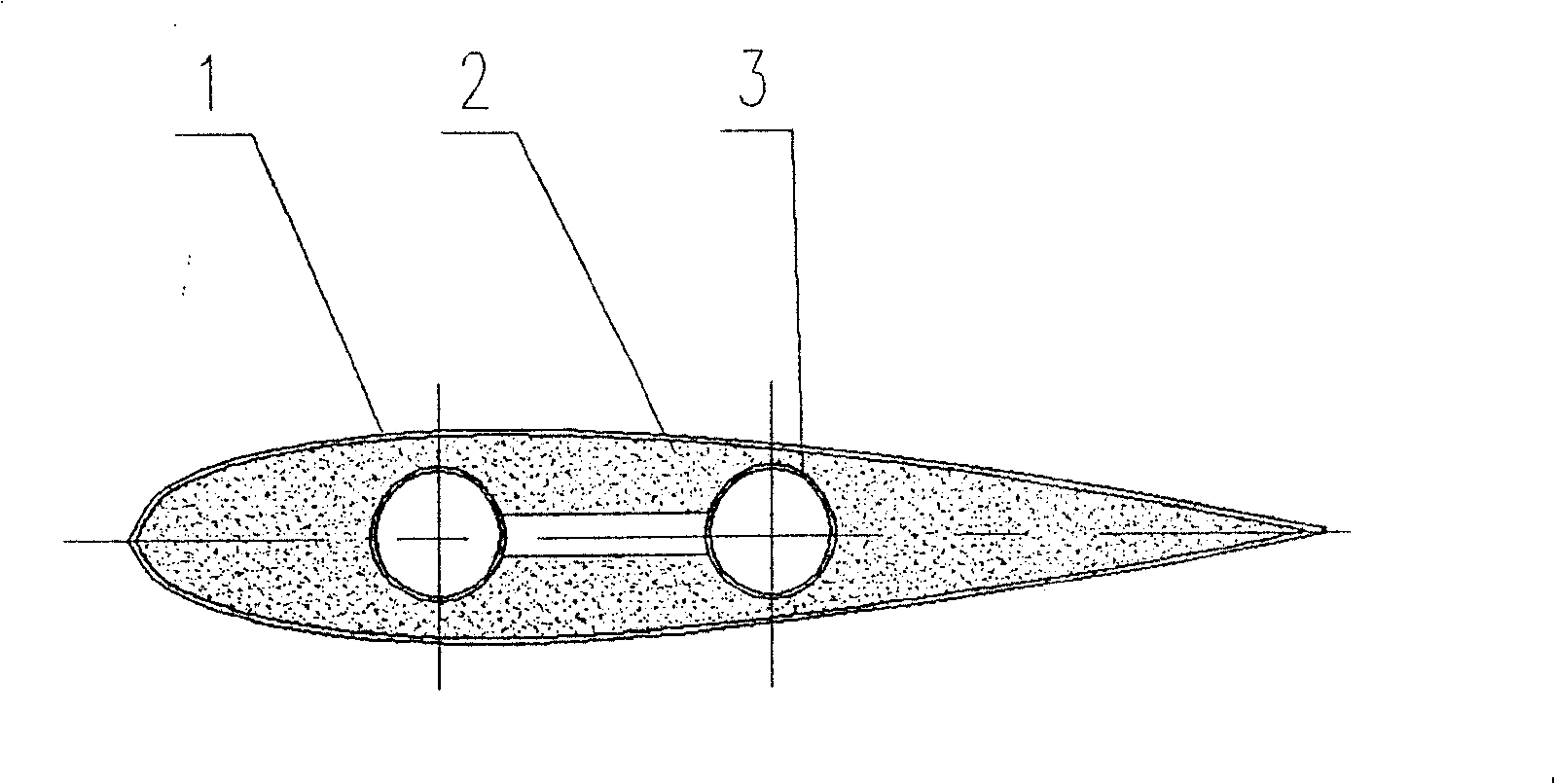

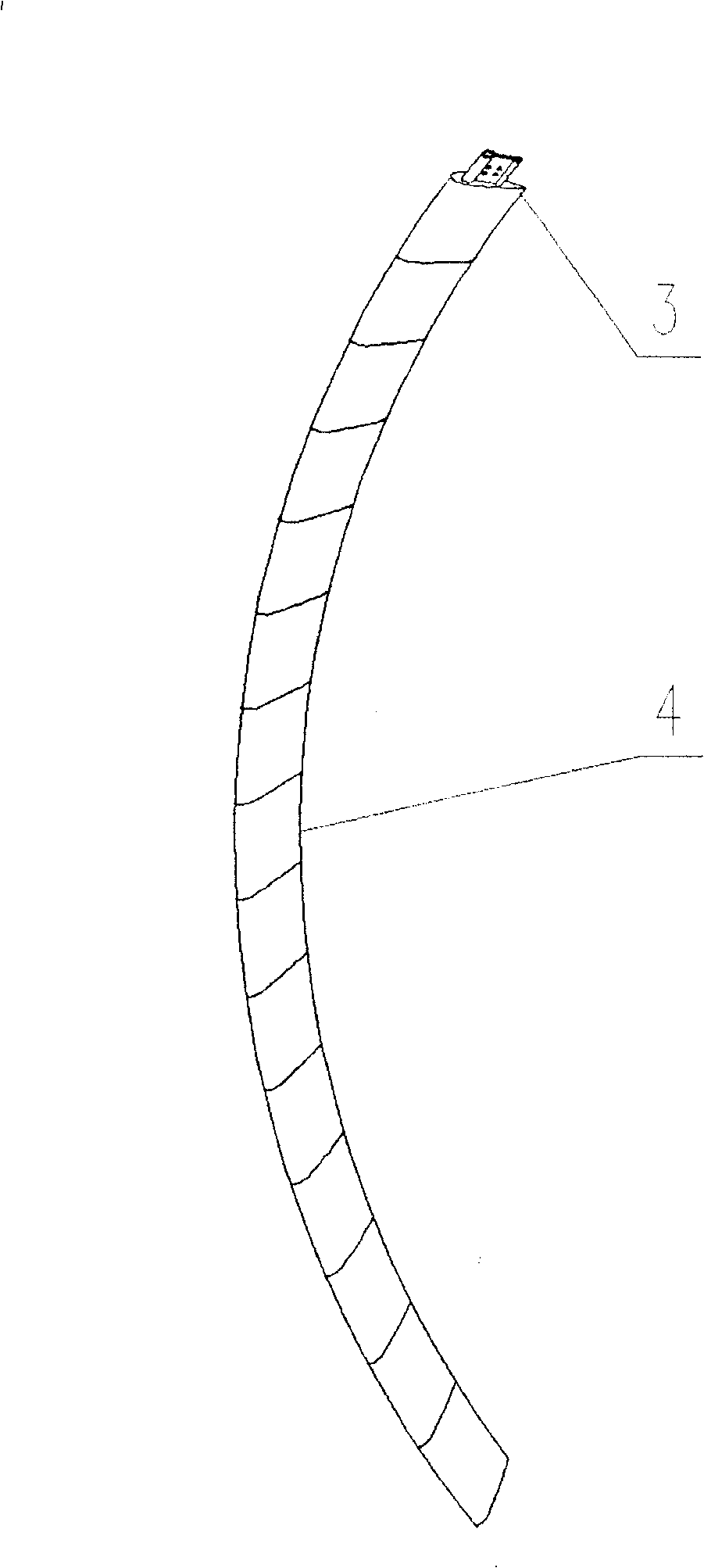

[0041] A blade for a vertical axis wind power generator and its manufacturing process according to the present invention will be described in detail below with reference to the accompanying drawings. figure 1 , figure 2It is a schematic diagram of the cross-sectional structure of the blade of the blade for the vertical axis wind power generator of the present invention in two main beam forms. The blade adopts inner, middle and outer three-layer structure; the outer structure is thin-walled skin 1, and the surface is processed into the shape required by the blade; the dimensional accuracy and surface finish of the blade are guaranteed to obtain the required aerodynamic performance and withstand the aerodynamic load on the blade surface And protect the middle filling body from the sun's ultraviolet radiation aging, air corrosion and oxidation. The middle structure is the filling body 2, which can fill all or part of the space between the skin and the main beam, and play the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com