Dehydrated ultra thick oil pipeline transportation method and corollary arrangement

A technology for pipeline transportation and ultra-heavy oil, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as lack of mature experience in submarine pipelines, and achieve the effect of reducing heat dissipation loss and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] On October 1, 2004, the world's first super-heavy oil pipeline from Shuguang Special Oil No. 2 Station to Liaohe Petrochemical Company's super-heavy oil pipeline was completed and put into operation. The purpose of this project is to provide raw materials for the delayed coking unit of Liaohe Petrochemical Company. The following methods are used for the dehydration of heavy oil:

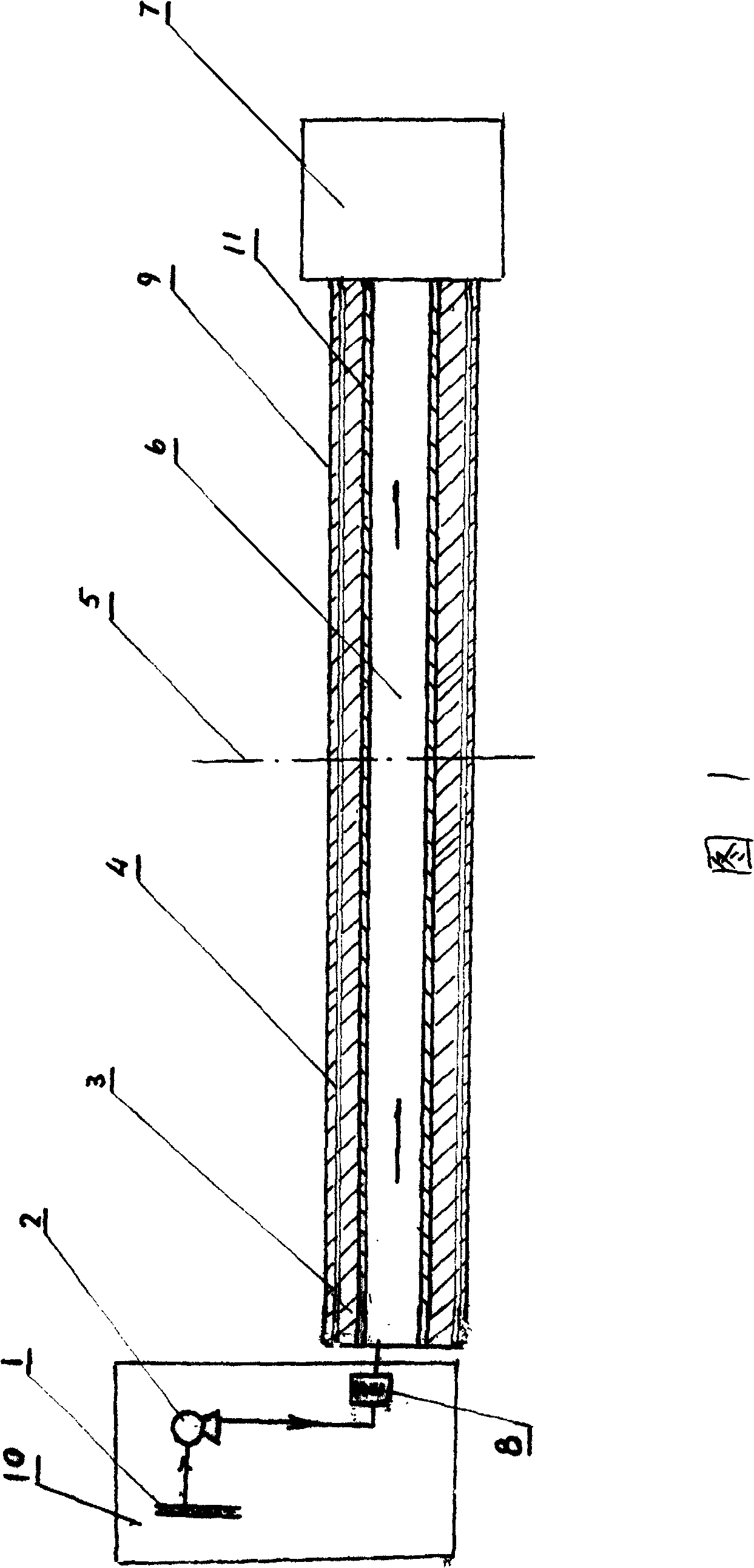

[0054] The starting point of the project is located at the first station 10 of Teyou No. 2, and the end point is at the last station 7 of the refinery. The oil transportation capacity of the pipeline in the super heavy oil area is 100×14 4t / a, with a first station 10, an intermediate heat pump station 5, an oil delivery station 7 and a 26-kilometer oil pipeline, and equipped with a skin effect heat tracing device 4, when the heavy oil super oil of Shuguang Special Oil No. 2 station is at a temperature of 50 ℃ , Viscosity 115893.0MPa·S Oil pipeline uses domestic L360 spiral seam submerged arc ...

Embodiment 2

[0061] The present invention applies dehydrated ultra-heavy oil buried pipeline anti-corrosion, heat preservation structure and oil pipeline skin effect heat tracing, and supplements the heating mode through the intermediate heat pump station 5. Therefore, in the process of oil transportation, it is not affected by the terrain environment and cooling. During the 30-kilometer-long pipeline transportation process, oil was successfully delivered once.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com