Cell polar-piece coating continuous-rolling system

A battery pole piece and coating technology, which is applied in the direction of electrode manufacturing, coating, metal rolling, etc., can solve the problems of not being able to form an automated production line, occupy a large area, and crack pole pieces, so as to avoid tension oscillation instability , Improve production efficiency and reduce deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

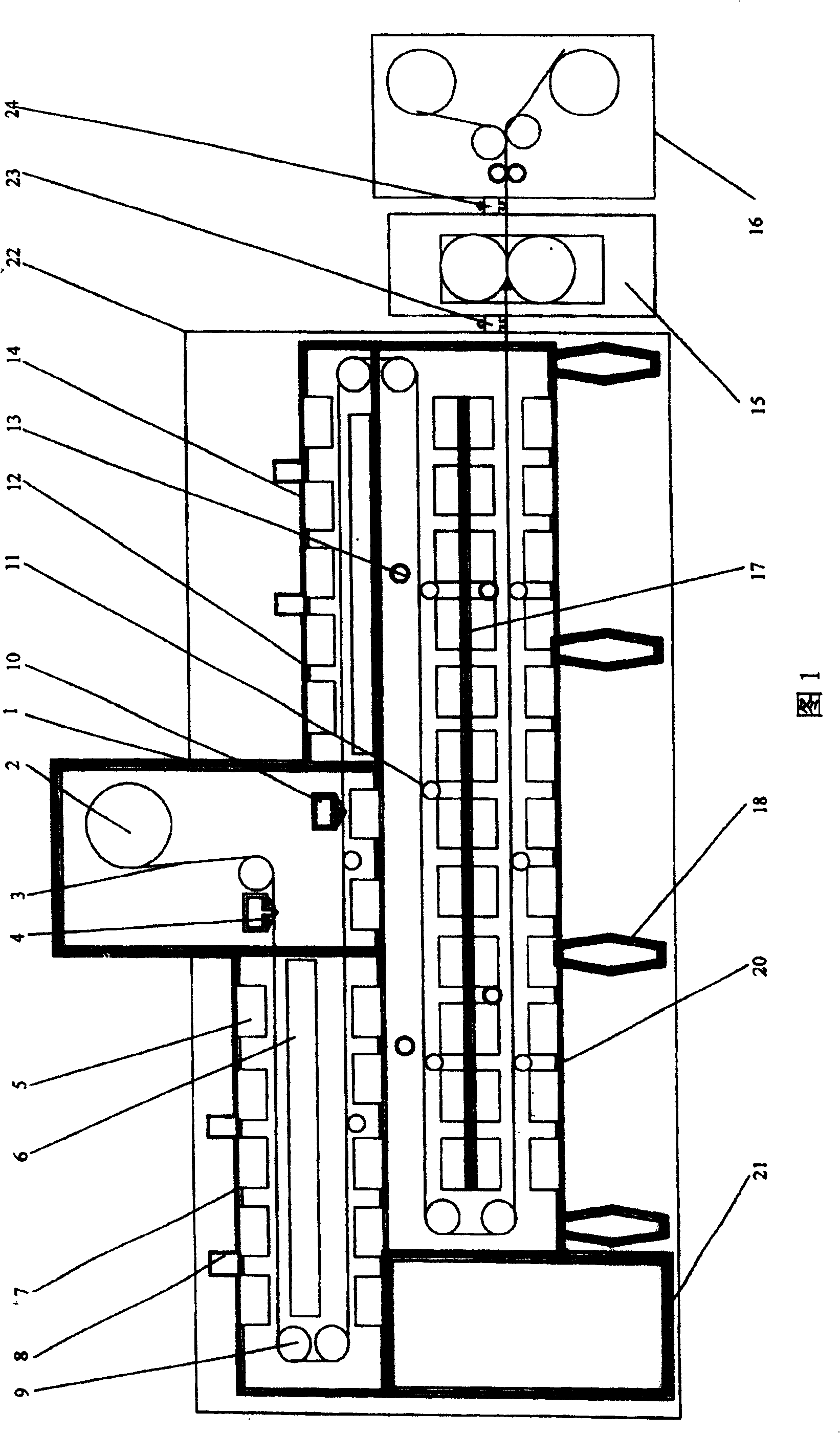

[0006] The invention provides a battery pole piece coating continuous rolling system used for coating and rolling the active material of the lithium battery pole piece. In the schematic structural view of the battery pole piece coating continuous rolling system shown in FIG. 1 , the first tension sensor 23 is installed between the first part of the double-sided slot die extrusion coating machine 22 and the second part of the battery pole piece rolling machine 15; The second tension sensor 24 is installed between the second part of the battery pole piece rolling mill 15 and the third part of the continuous slitting machine 16; the sealing coating box 1 is installed in the middle of the double-sided slot die extrusion coating machine 22. A constant tension automatic deviation correction unwinding device 2 , a first slot die extrusion coating head 4 and a second slot die extrusion coating head 10 are installed in the sealed coating box 1 . The upper part of the first drying box 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com