Piezoelectric three dimension acceleration sensor

A three-dimensional acceleration and sensor technology, which is applied in the direction of multi-dimensional acceleration measurement and acceleration measurement using inertial force, etc., can solve the problems of sensor volume and self-heavy, inability to overcome measurement error, low sensitivity, etc., and achieve simple structure, light weight, and high sensitivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

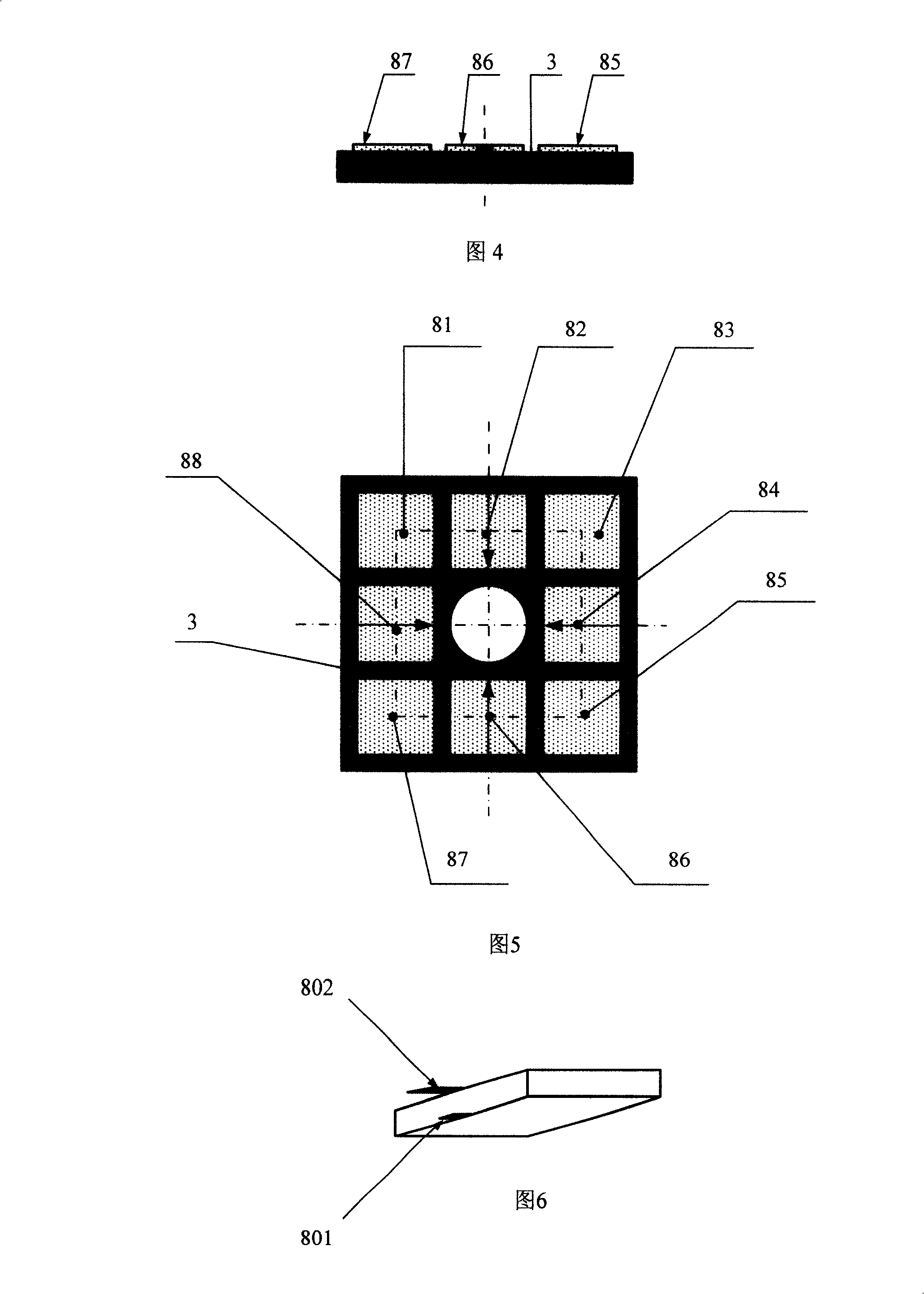

[0017] Embodiment 1 (with reference to Fig. 4,5,6):

[0018] This example is on the basis of the general description part, further refinement in improving the processing technology of the present invention, in this example, each quartz wafer (81,82,83,84,85,86,87,88) Each of the two sides has an electrode ( 801 , 802 ) connected to a corresponding signal lead, and all the electrodes ( 801 , 802 ) are located at the edge of the wafer positioning frame 3 .

Embodiment 2

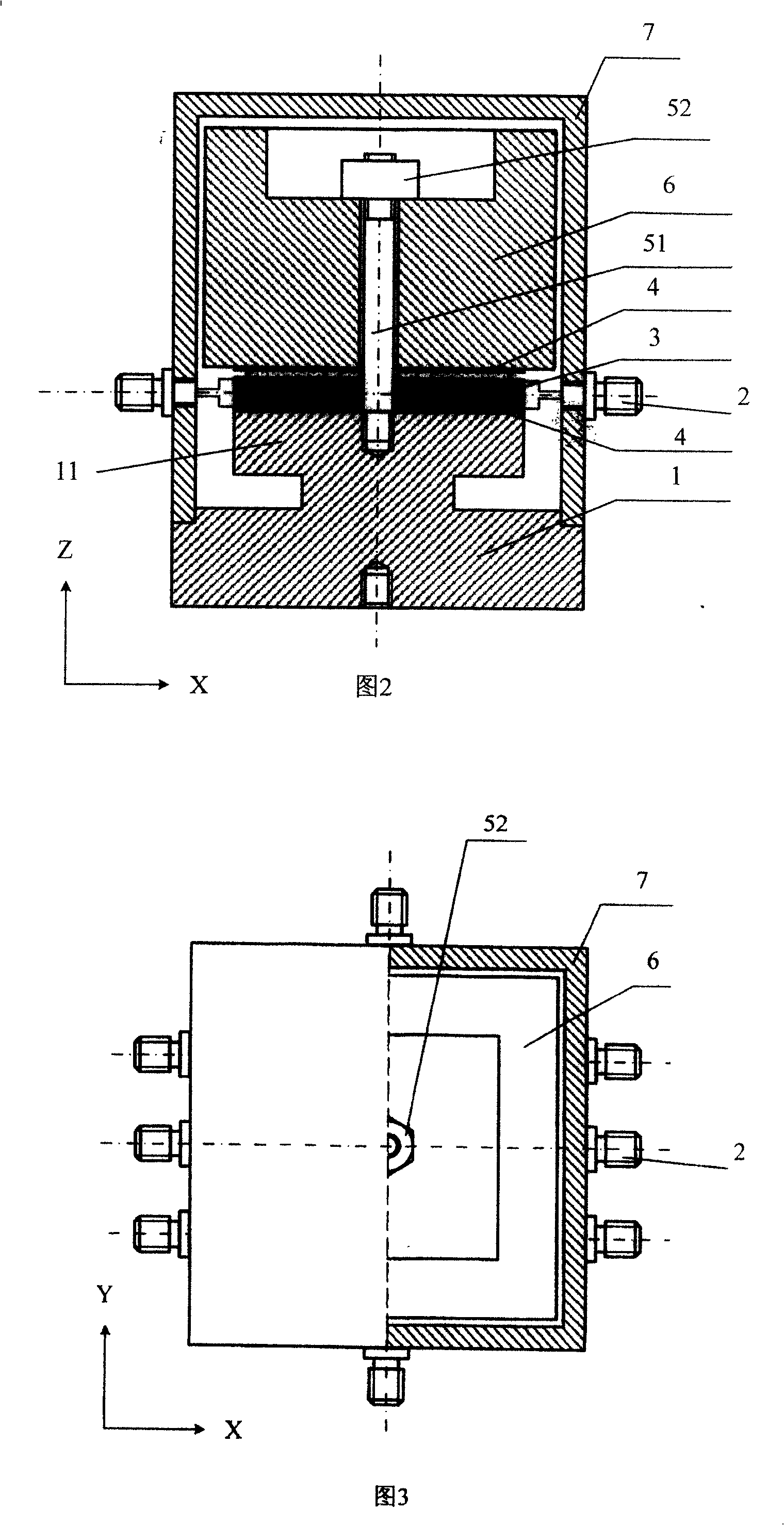

[0019] Embodiment 2 (with reference to Fig. 2):

[0020] This example is based on the general description or Example 1, and is a specific example for the isolation base therein. In this example, the cross-section of the solid part of the annular groove between the waist of the isolation base 1 is a square (this cross-sectional view is not drawn), its four sides are parallel to the four sides of the base mounting plate 11, and its perimeter is equal to the base mounting plate 1 / 2 of the circumference of 11 (obviously, the solid part of the annular groove and the axis of the base mounting plate 11 are all coaxial with the pre-tightening bolts).

Embodiment 3

[0021] Embodiment 3 (with reference to Fig. 2):

[0022] This example is based on the general description or Example 1, and is a specific example for the isolation base therein. In this example, the cross-section of the solid portion of the waist ring groove of the isolation base 1 is circular (the cross-sectional view is not shown), and its diameter is 1 / 2 of the length of any side of the base mounting plate 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com