Method for preparation of a-b orientated ZnO nanometer linear array

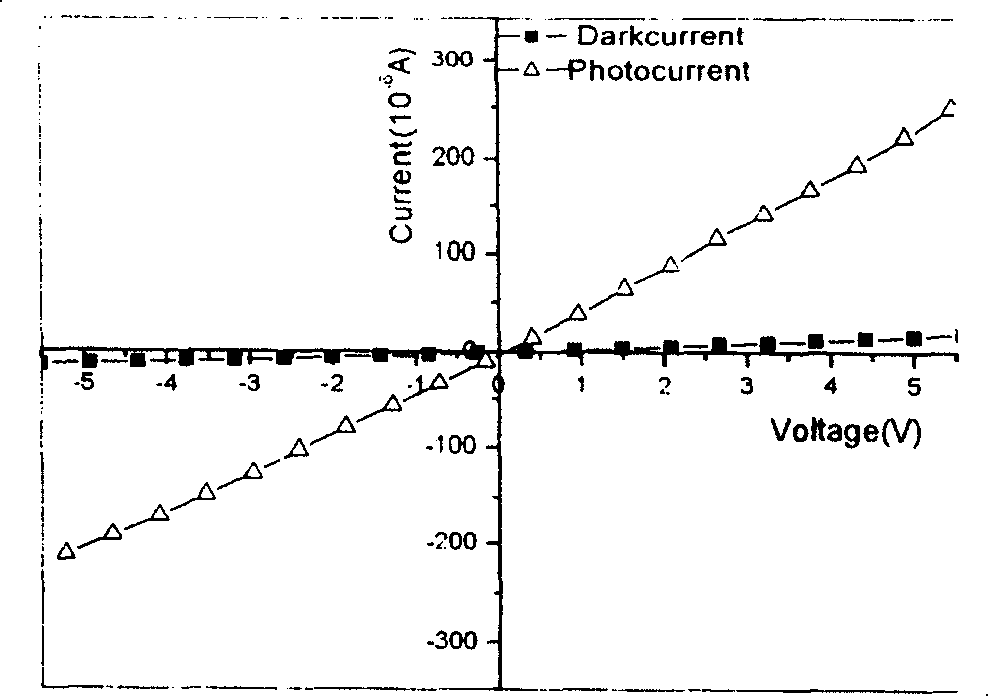

A nanowire array and orientation technology is applied in the field of preparation of ZnO nanowire arrays to achieve the effects of excellent ultraviolet light sensitivity, fast light response speed and high deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

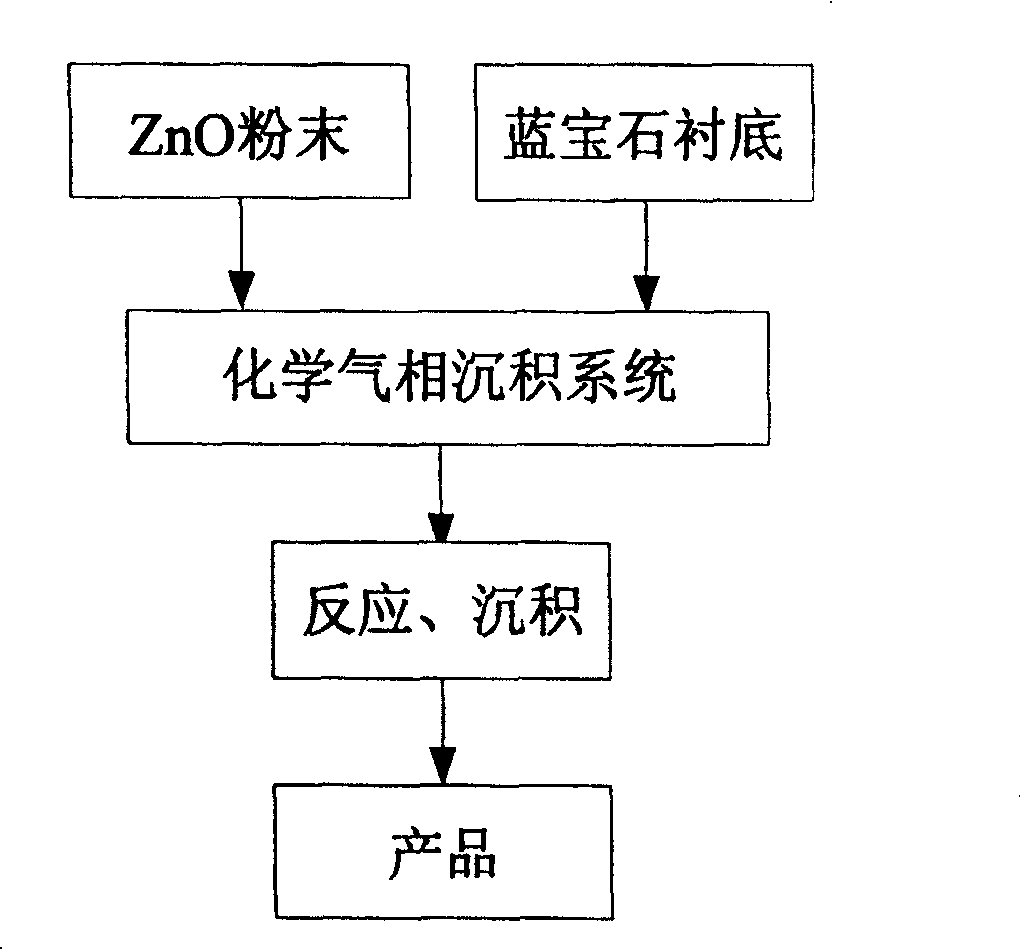

[0026] In the present invention, the ZnO nanowires are prepared by using a dual-temperature zone CVD system. The whole system can be divided into gas circuit part, growth chamber and control part.

[0027] The specific implementation steps are as follows:

[0028] 1. Preparation of Evaporation Source

[0029] In the present invention, analytical pure ZnO powder produced by Tianjin Institute of Chemical Reagents is used as evaporation source.

[0030] 2. Sapphire Al 2 O 3 (1120) cleaning step of substrate substrate:

[0031] 1) scrubbing;

[0032] 2) Soak: use potassium dichromate solution, then wash with deionized water;

[0033] 3) Ultrasonic cleaning 1: deionized water, 5 to 10 minutes, twice;

[0034] 4) Ultrasonic cleaning 2: 5 to 10 minutes in acetone, twice;

[0035] 5) Ultrasonic cleaning 3: in absolute ethanol, 5 to 10 minutes, twice;

[0036] 6) drying;

[0037] 7) Standby.

[0038] 3. CVD synthesis of ZnO nanowires

[0039]Using the high temperature therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com