Method for producing semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as difficulty in controlling the depth of LDD and degradation of device performance, and achieve elimination of sags, simplification of the etching process, and good engraving The effect of eclipse selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] The invention discloses a method for manufacturing a semiconductor gate structure. The etching of the ONO stacked structure of SONOS devices with a thickness of 65nm and below has high precision. The method can be used to manufacture next-generation low-voltage high-density non-volatile semiconductor flash memory devices.

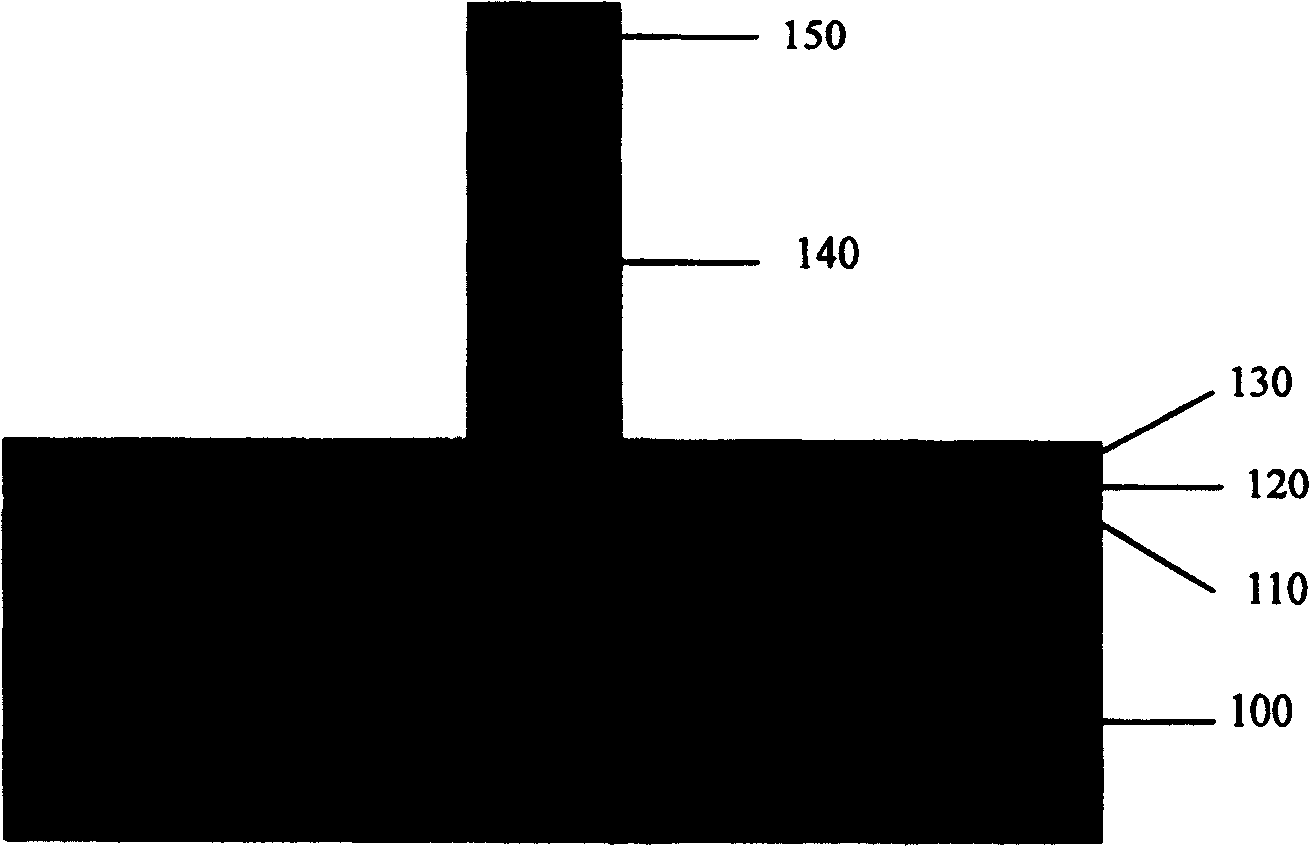

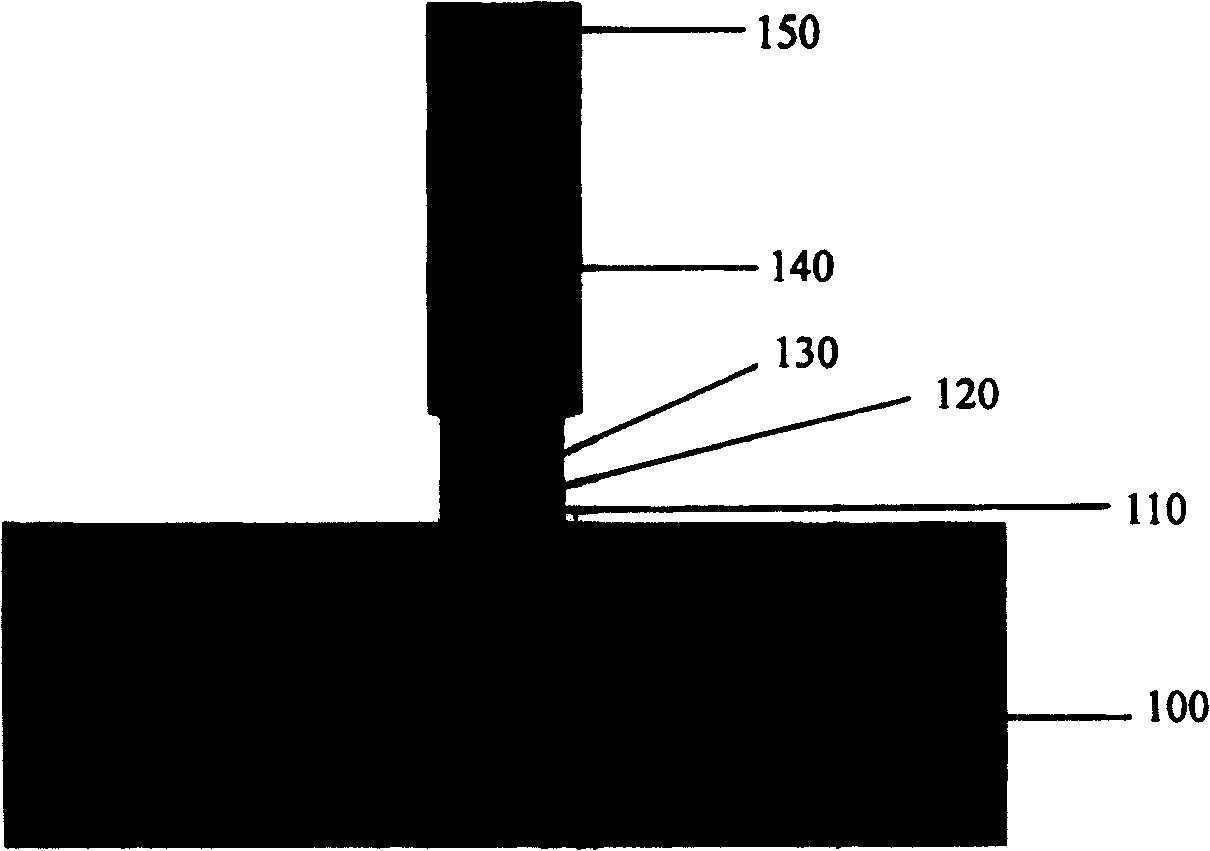

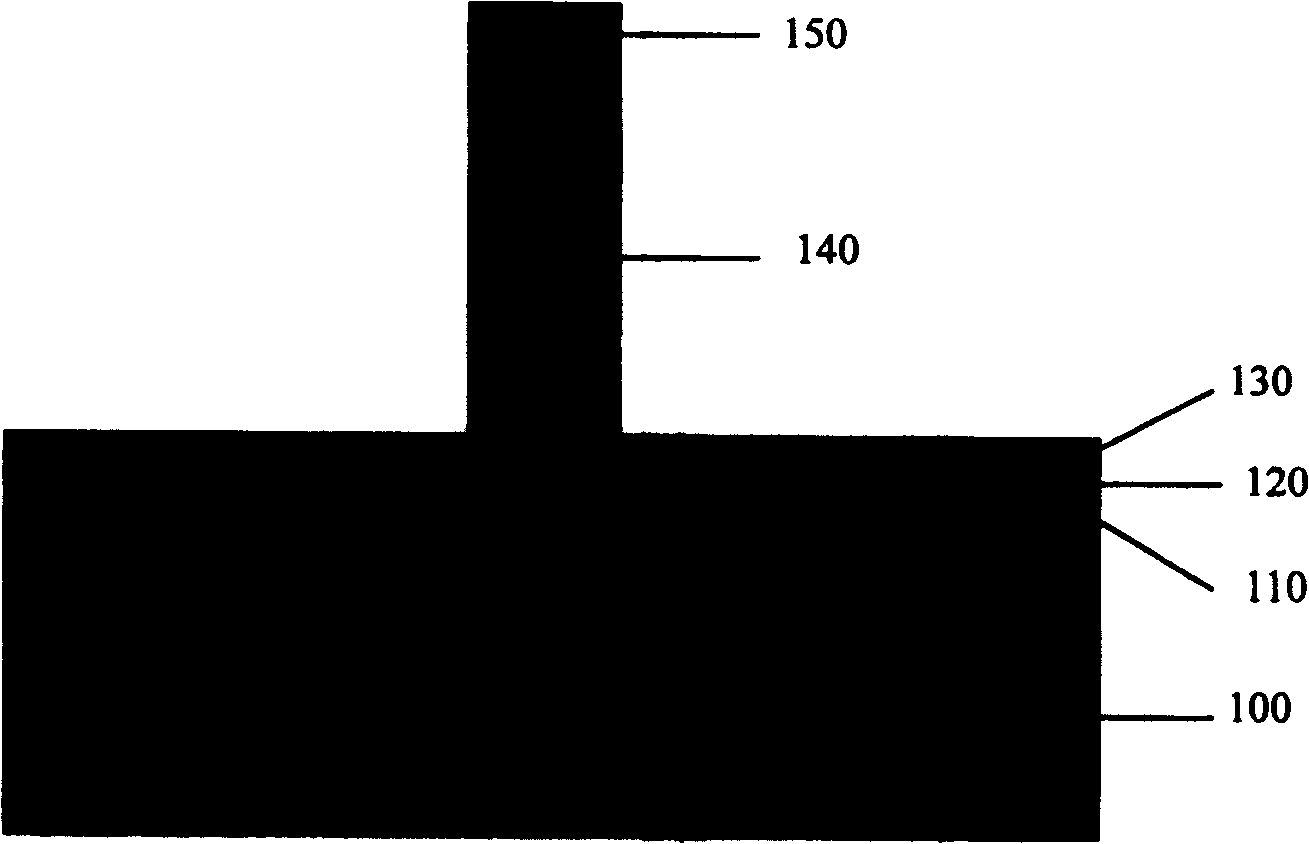

[0029] image 3 and Figure 4 It is a schematic diagram of the ONO stack structure of the SONOS device for illustrating the manufacturing method of the semiconductor gate structure of the present invention. SONOS (silicon-oxide-nitirde-oxide-silicon silicon-oxide-nitride-oxide-silicon) device is a new generation of non-volatile large-capacity semiconductor storage device, and its core structure is a polysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com