Heat sound driving pulse pipe refrigeration machine system

A technology of pulse tube refrigerators and thermoacoustic engines, which is applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., and can solve the problem of consumption, the decrease of the performance coefficient of thermoacoustic driven pulse tube refrigeration systems, and the reduction of the reliability of pulse tube refrigerators. sex and other issues to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

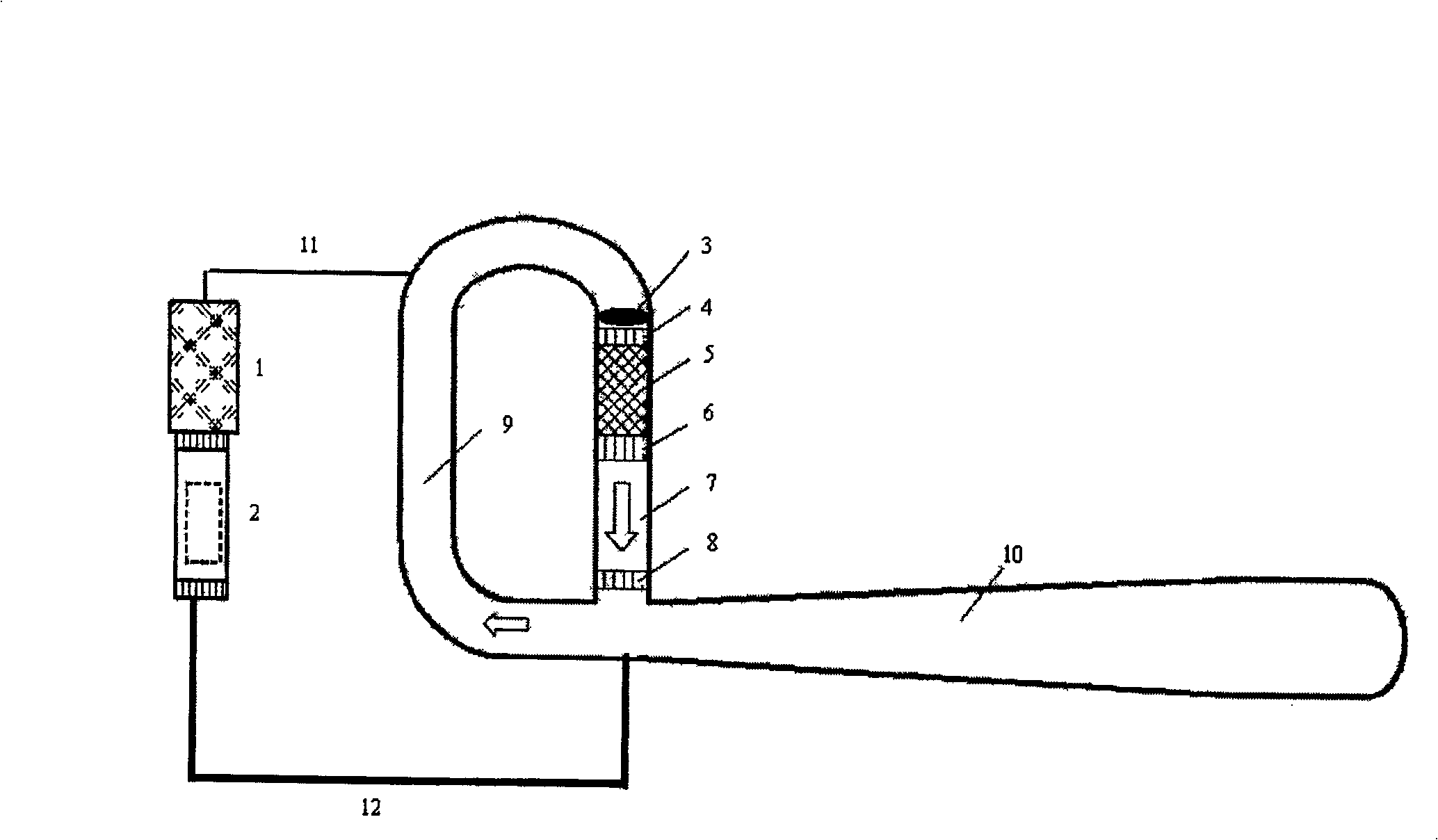

[0019] The thermoacoustic driven pulse tube refrigerator system shown in the accompanying drawing is composed of a traveling wave thermoacoustic engine, a pulse tube refrigerator and other accessories. A pulse tube refrigerator has a refrigerator regenerator 1 and a pulse tube 2 connected in sequence, and a traveling wave thermoacoustic engine has a traveling wave loop and a resonant straight path 10, wherein the traveling wave loop has a DC control component 3 and a main cooling circuit connected in sequence. 4, engine regenerator 5, heater 6, heat buffer pipe 7, sub-cooler 8, feedback loop 9. The hot end of the regenerator of the pulse tube refrigerator is connected to the thermoacoustic engine through a pipeline 11 with an inner diameter of about 8 mm, which is used to transmit sound power from the thermoacoustic engine into the pulse tube refrigerator. A slender tube with an inner diameter of about 1 to 4 mm and a length of 2 to 5 m is connected to the hot end of the pulse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com