Coal hydrogenation reaction device and its industrial application

A reaction device, coal hydrogenation technology, applied in the petroleum industry, chemical/physical/physicochemical nozzle reactors, preparation of liquid hydrocarbon mixtures, etc., can solve the problems that cannot meet the demand and cannot realize large-scale industrial production , to achieve the effect of flexible and convenient operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

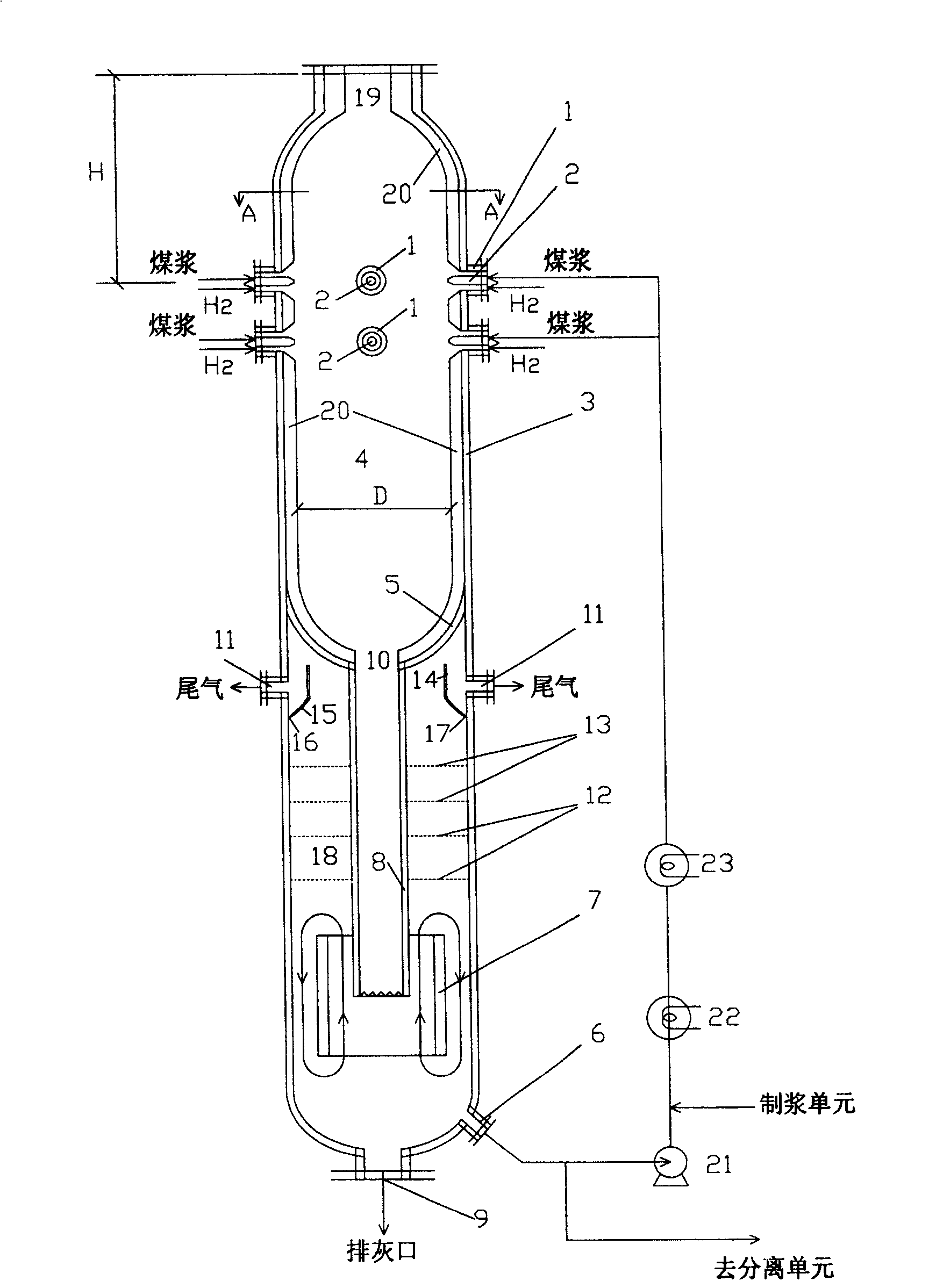

[0062] A super-large hydrogenation reaction unit with an annual output of 5 million tons of oil, with a daily coal processing capacity of 42,000 tons, a reactor inner diameter of 6500 mm, an entrained flow bed height of 48 m, and a bubbling bed height of 40 m, totaling a total height of 98 m.

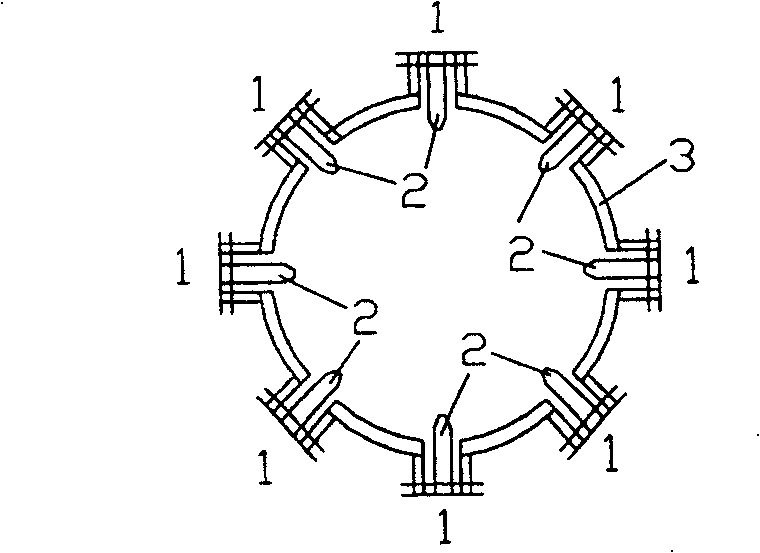

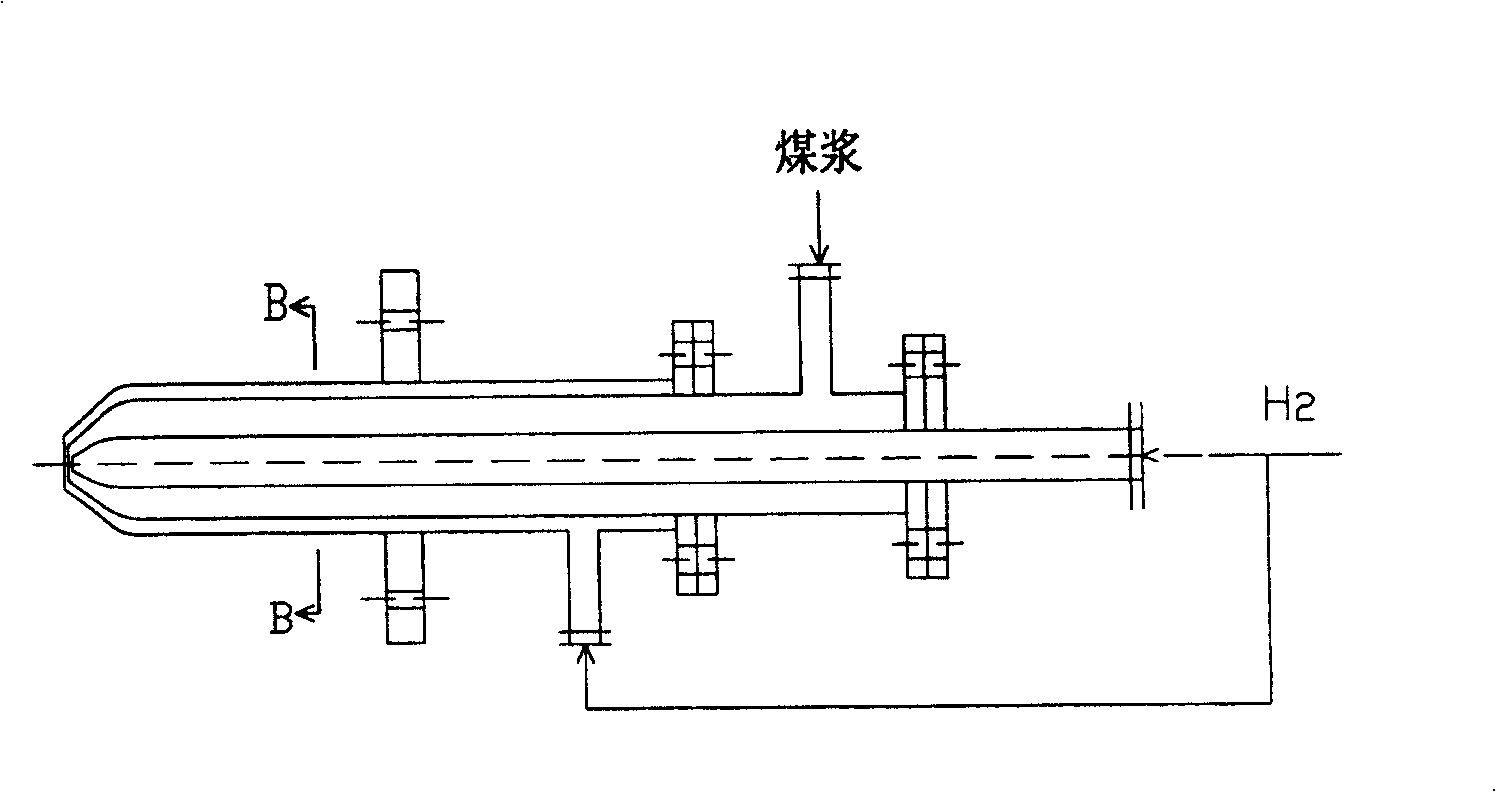

[0063] Adopt the nozzle described in the patent ZL95111750.5, with a single row of nozzles, a total of 8, the distance H between the horizontal plane of the nozzle 2 and the upper nozzle chamber on the air flow bed is 6500mm;

[0064] In the pulping unit, coal is mixed with circulating solvent and catalyst (the amount of catalyst is 1-5% of the weight of coal), and the solid particle size of the product is ≯200μm, and the weight concentration of coal slurry is 50%. After sieving, it is pumped to the hydrogenation reaction device , enter the hydrogenation reaction device through the second channel 202 of the nozzle 2, hydrogen (total flow is 1400000Nm 3 / h) Enter the hydrogenation reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com