Gas firing wall stove with balanced forced air exhausting system

A balanced, gas-fired technology, applied in the direction of air induction, combustion methods, combustion equipment, etc., can solve problems such as installation restrictions, low smoke exhaust wind speed, and reduced thermal efficiency, and achieve the effects of preventing backflow, increasing safety measures, and preventing deflagration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

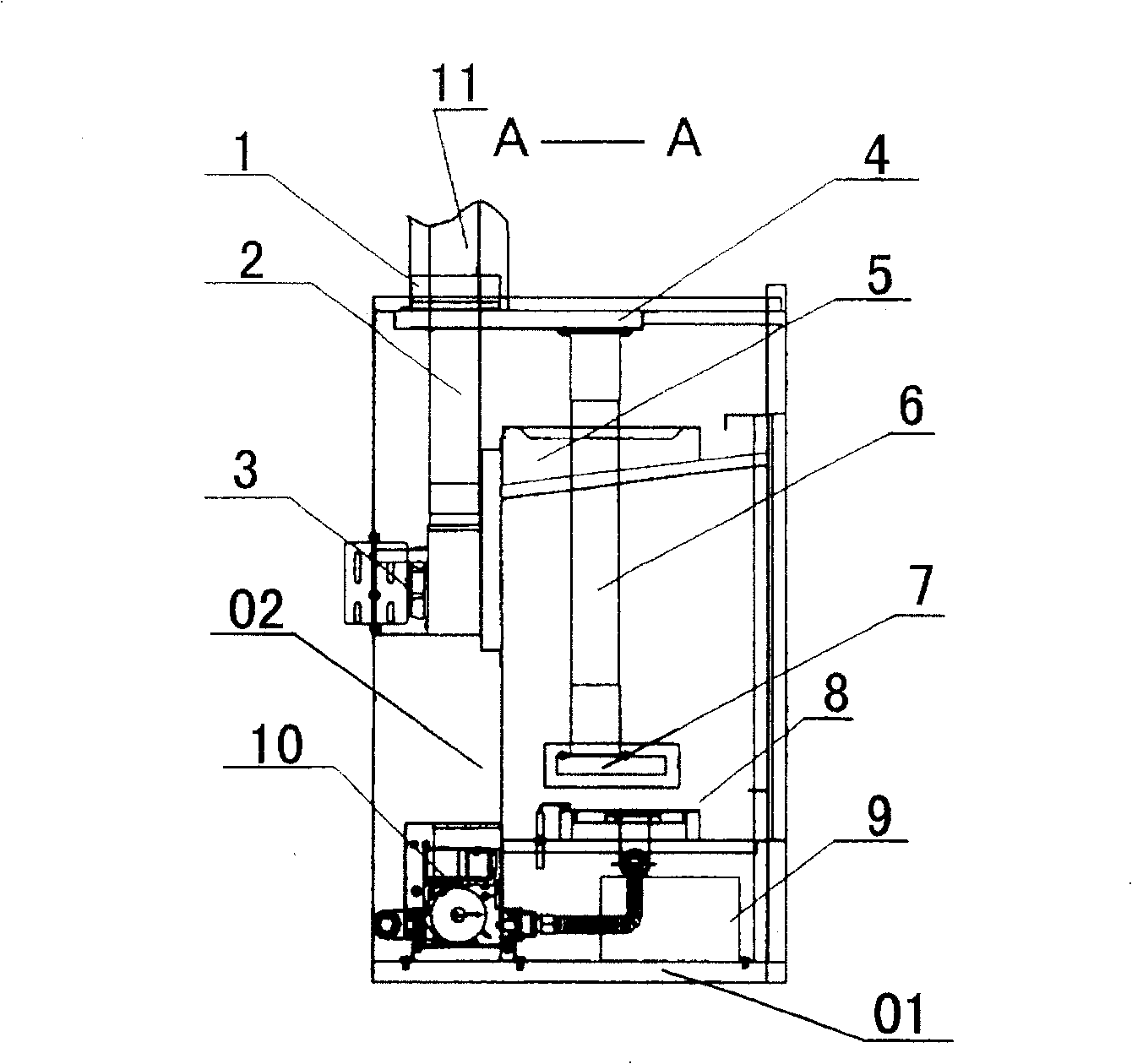

[0020] The structure of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

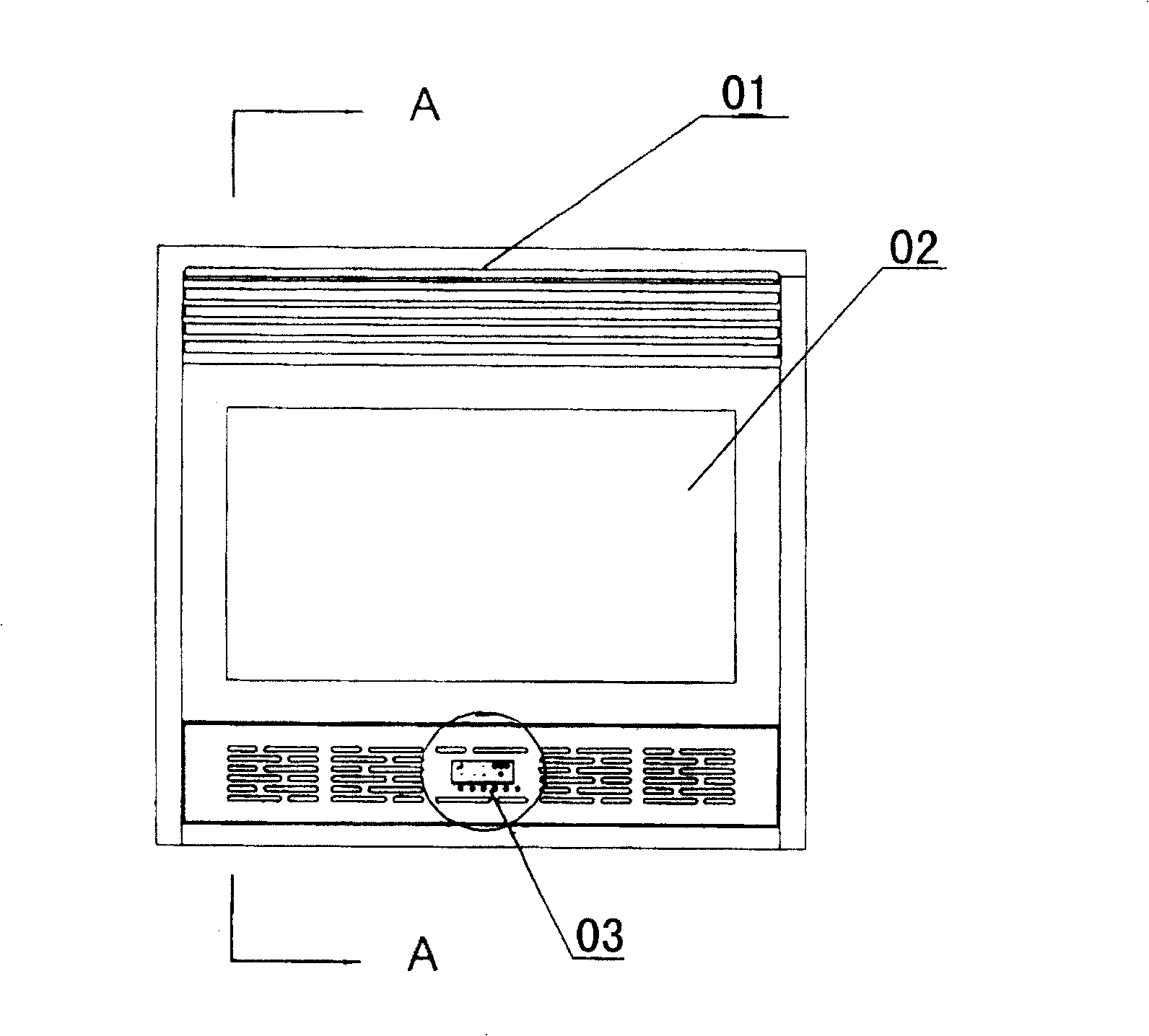

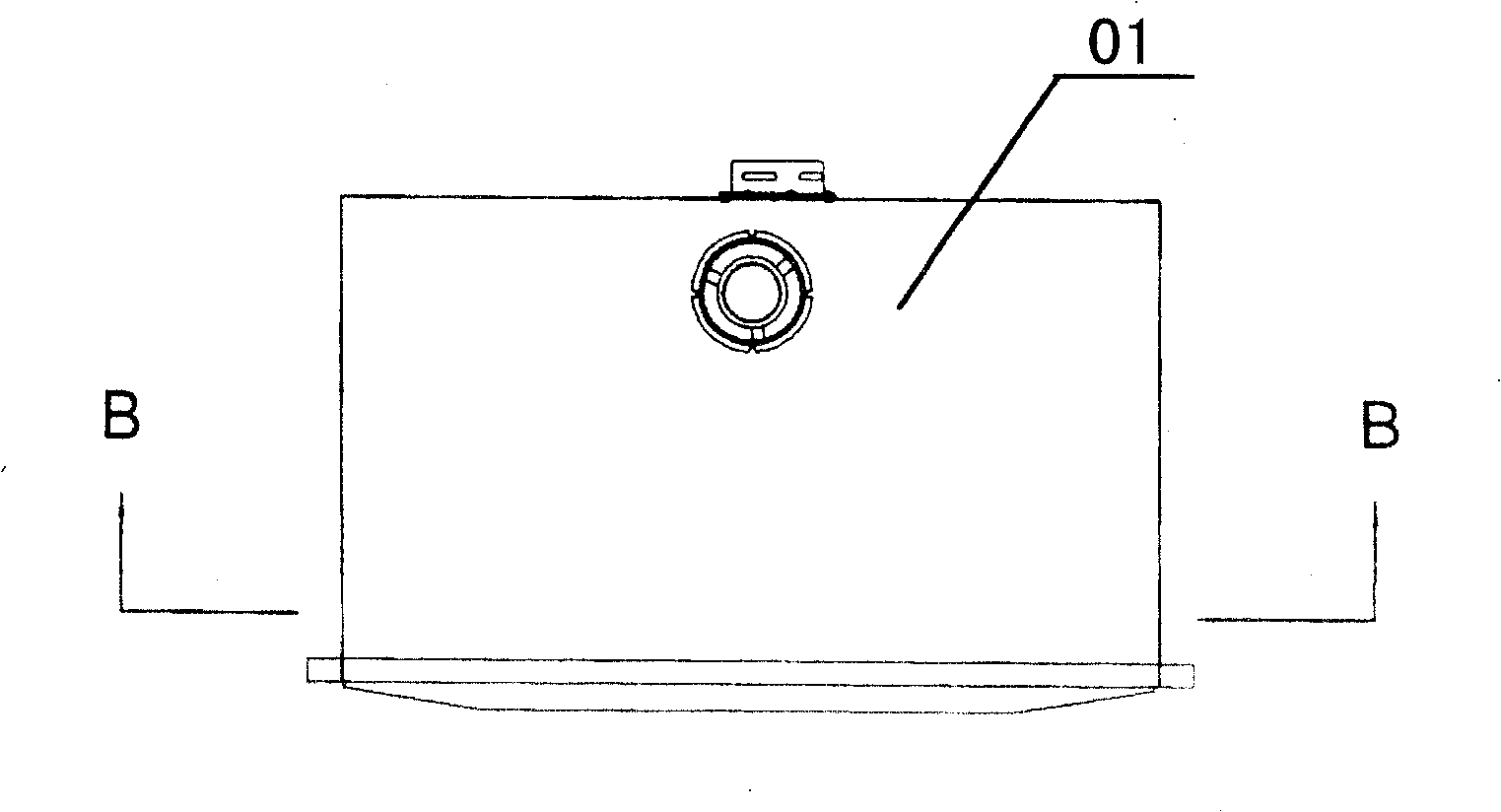

[0021] figure 1 , 2 , 3, 4 are structural schematic diagrams of an embodiment of the gas fireplace of the present invention.

[0022] Such as figure 1 , 2 , 3, and 4, the gas fireplace of the present invention includes: a shell 01, a hearth 02 surrounded by the shell 01, a burner 8 placed in the hearth 02, a gas delivery pipeline and a gas control valve connected to the burner 8 10. The control system 9 placed on the shell 01 and the balanced forced exhaust system placed in the furnace 02.

[0023] Such as image 3 , 4 As shown, the balanced forced exhaust system includes a smoke collection hood 5 above the burner 8, a strong exhaust fan 3 placed next to the smoke collection hood 5 (on the side), placed on the exhaust outlet of the strong exhaust fan 3 The smoke exhaust pipe 2 is placed on the smoke exhaust air inlet conversion p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com