Moulding method

A molding and mold technology, applied in the field of molding, to achieve the effect of preventing adhesion on the side of the cavity and reducing mold separation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, embodiments of a molding method and a molding machine according to the present invention will be described with reference to these drawings.

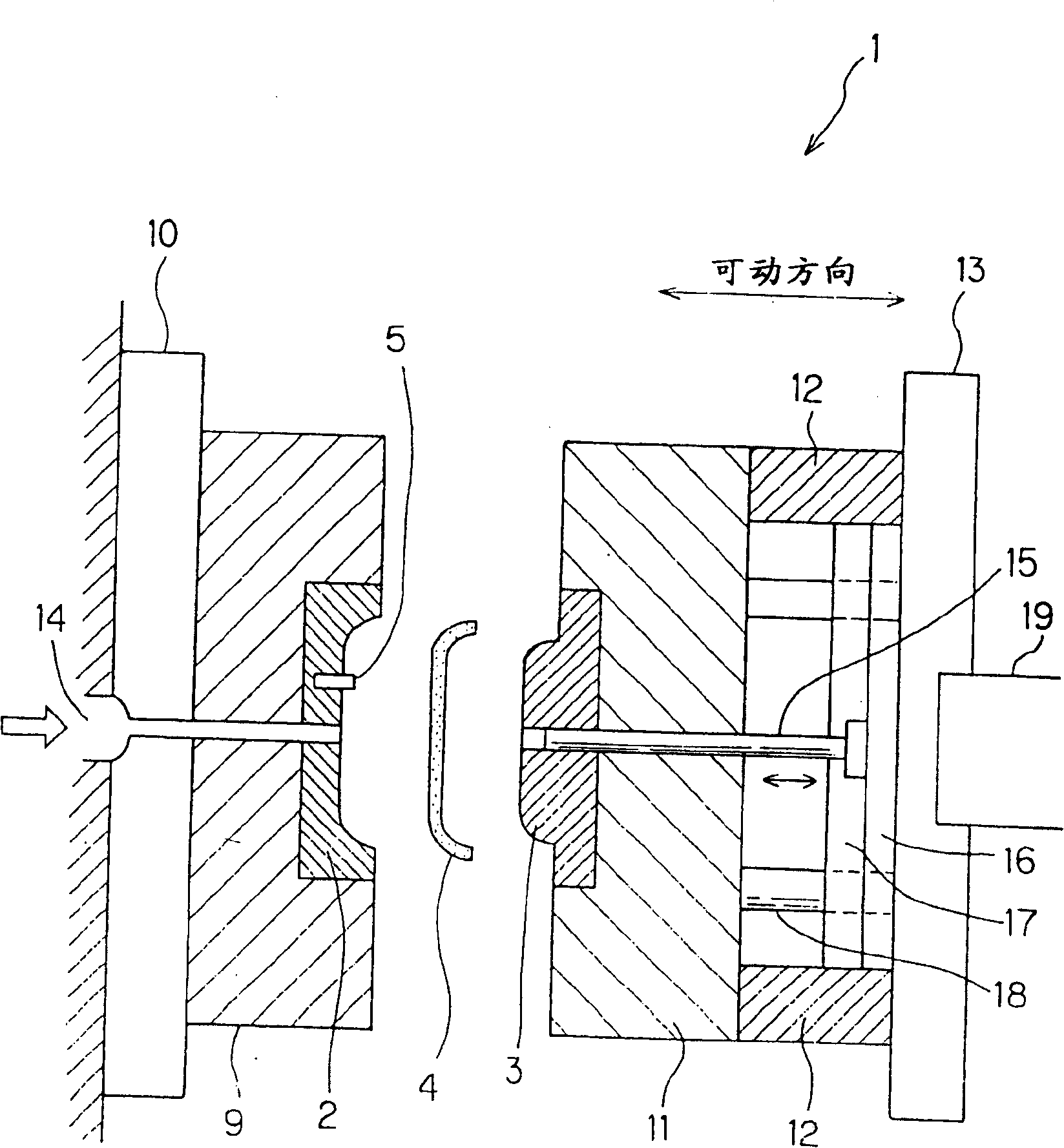

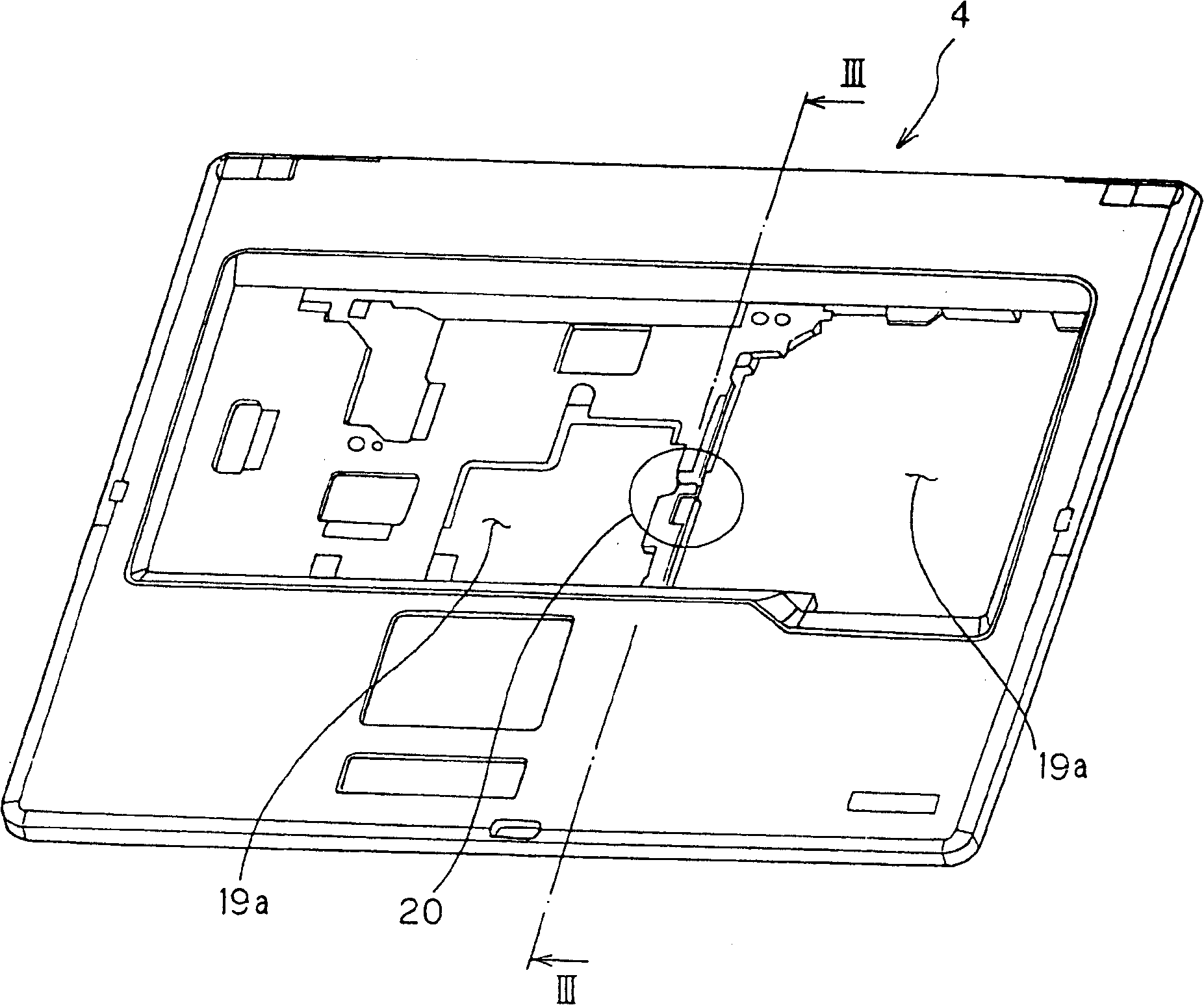

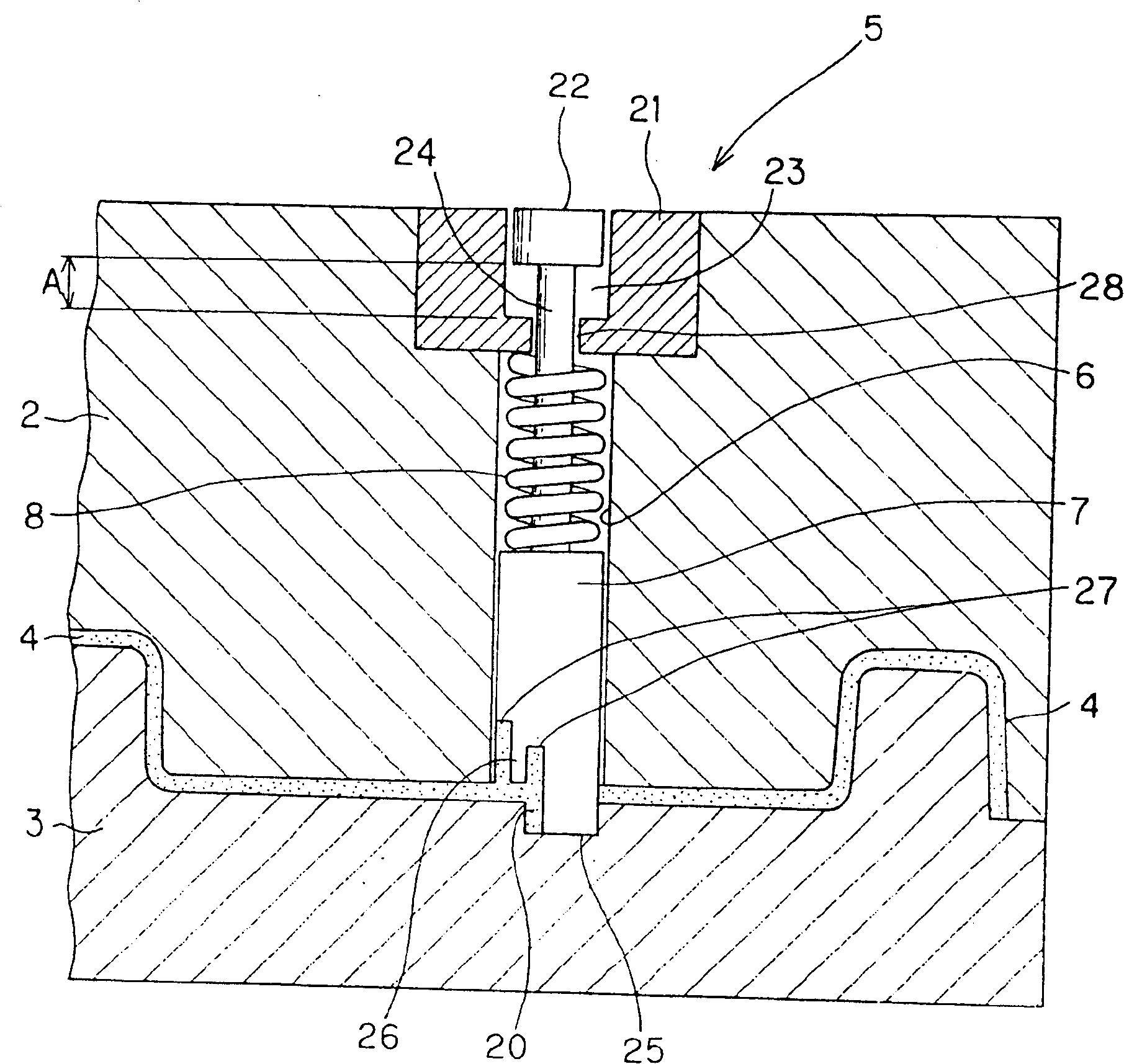

[0028] figure 1 is a sectional view showing a schematic structure of an embodiment of a molding machine for carrying out the molding method according to the present invention, figure 2 is a perspective view of the outside of a personal computer (PC) casing as an example of a molding 4 obtained by using the molding method and molding machine according to the present invention, image 3 is a sectional view showing one structural example of the pressing member 5 .

[0029] The molding machine 1 according to the present invention is configured to inject a resin material into a mold through a cavity 2 defining the shape of the outer surface of the molded part and a core 3 defining the shape of the inner surface of the molded part. In the hollow space formed by closing the pair, and allowing the resin material to harden, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com