Motor casing for electric bicycle and manufacturing method thereof

A technology for electric bicycles and motor casings, which is applied in the direction of manufacturing motor generators, electric components, casings/covers/supports, etc. It can solve the problems of affecting the output power of the motor, affecting the yield of castings, and increasing the manufacturing cost. Significant progress, obvious substantive features, and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

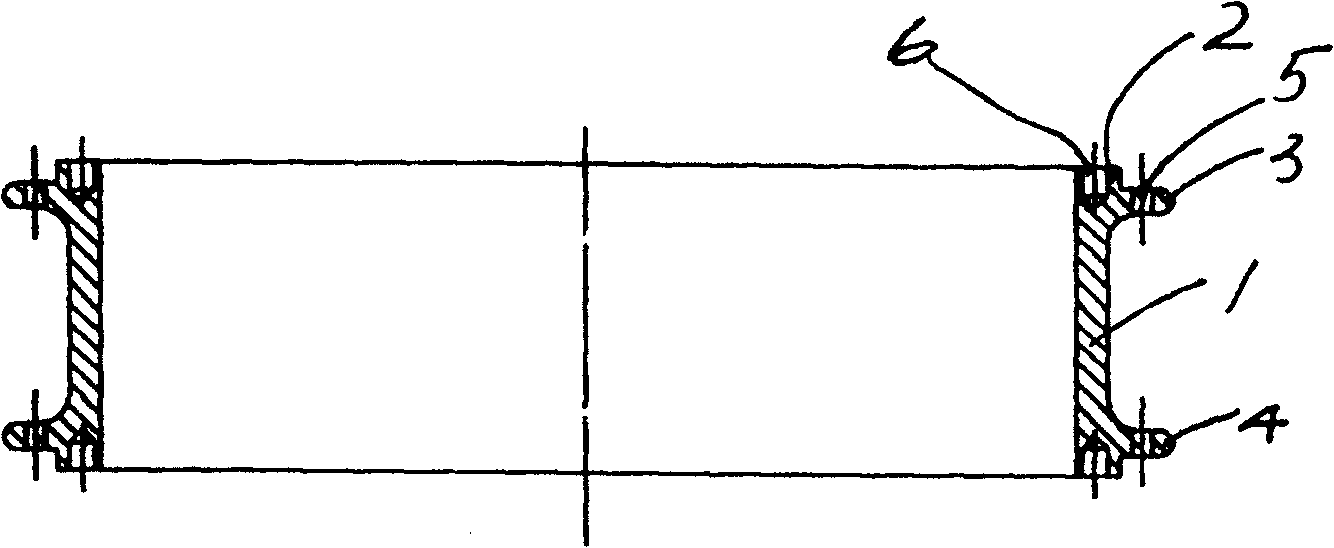

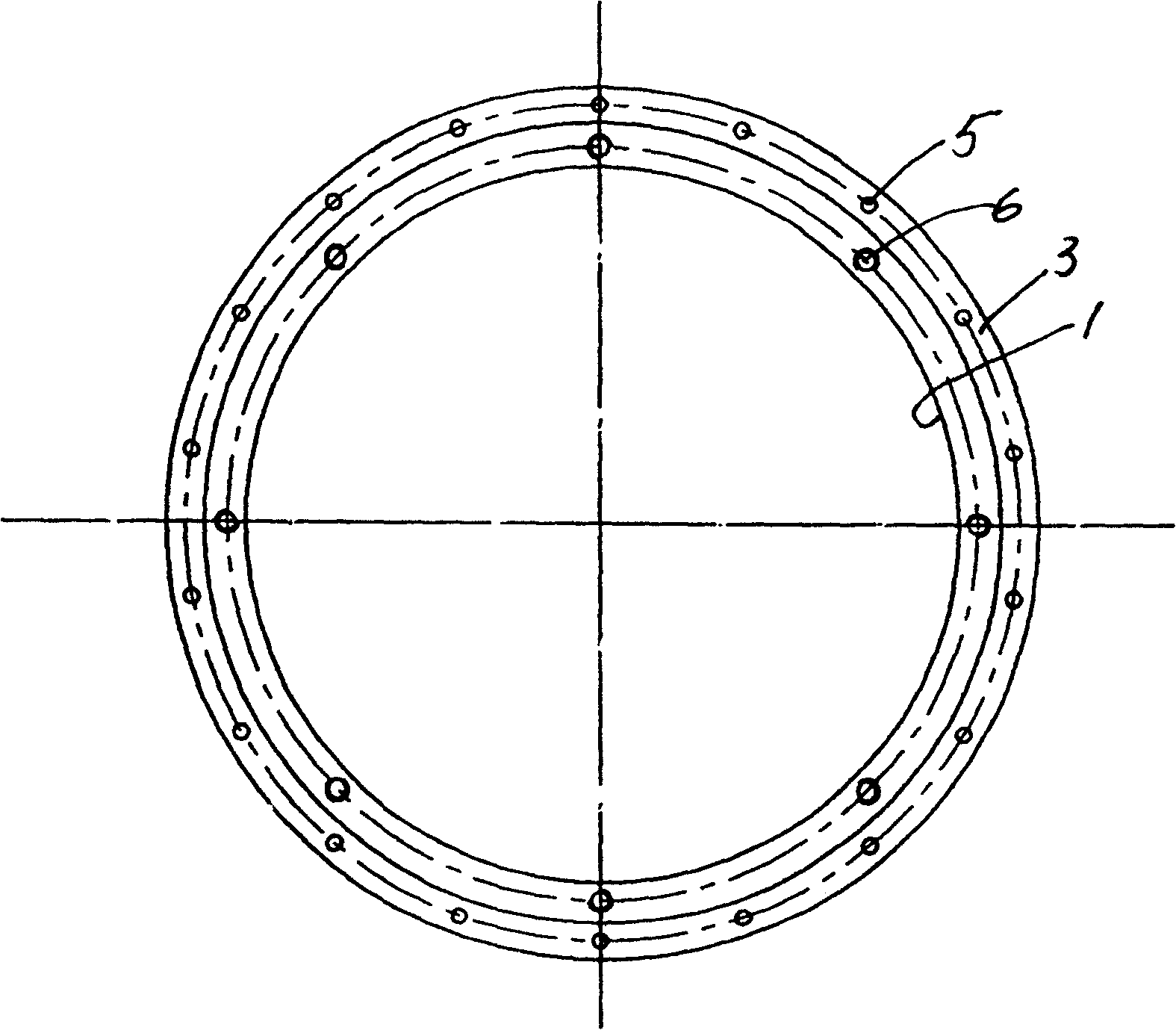

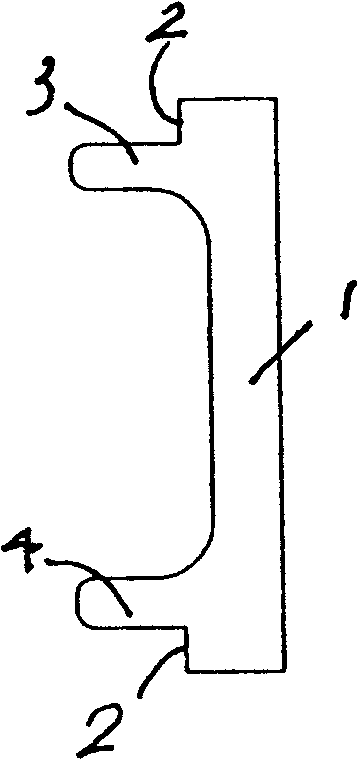

[0040] One of the specific implementation modes, as attached figure 1 , 2 shown. An electric bicycle motor shell, comprising a cylindrical shell 1; on the outer circle at both ends of the shell 1 there are protruding steps 2 along the circumferential direction, and next to the protruding steps 2 are arranged parallel to each other for The first flange 3 and the second flange 4 for fastening the spokes, the first flange 3 and the second flange 4 are respectively provided with several spoke fastening holes 5, and the two ends of the housing 1 are respectively provided with There are screw holes 6 corresponding to the screw holes of the motor end cover, and the housing 1 is in the form of a circular butt joint structure of rolled profiles with a protruding step 2, a first flange 3 and a second flange 4; the butt joint is a solder connection. The first flange 3 and the second flange 4 are each provided with 18 spoke fastening holes 5 of φ3.2 mm uniformly distributed along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com