Rotary pontoon type soft-drive sea-wave hydraulic power generation unit

A technology of rotating blades and waves, applied in ocean energy power generation, mechanical equipment, engine components, etc., can solve the problems of small power generation of a single generator and can not guarantee the power generation, achieve short manufacturing cycle, low cost, and meet the needs of power generation. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

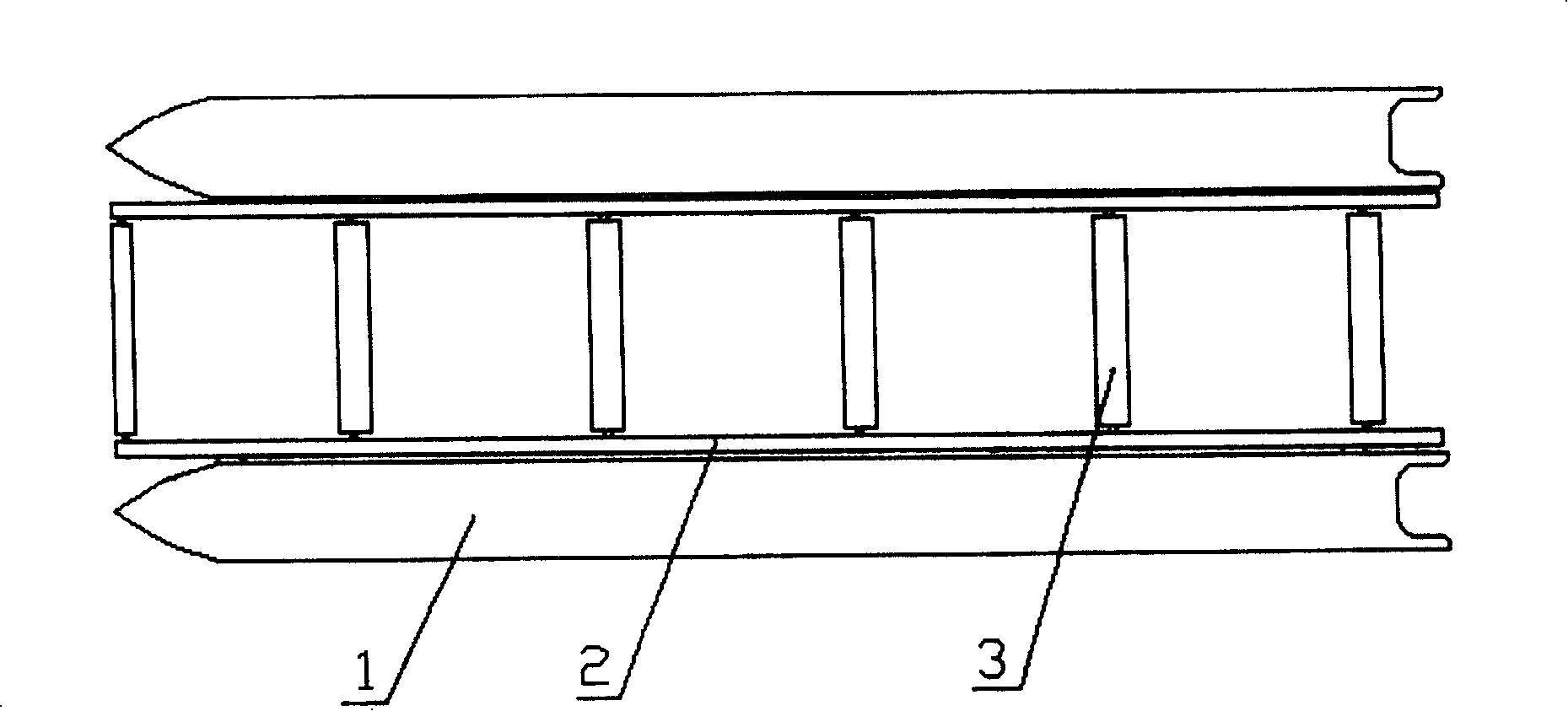

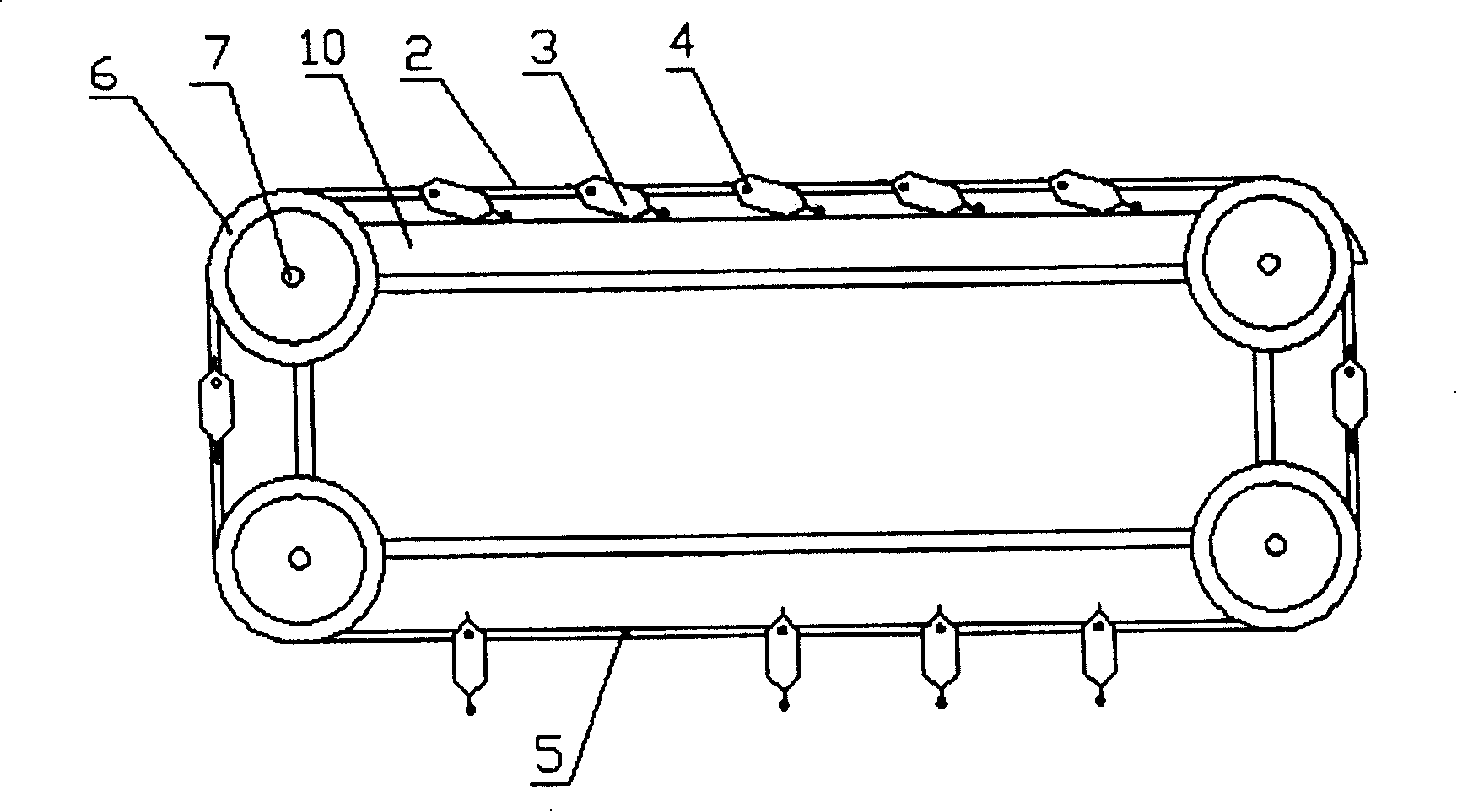

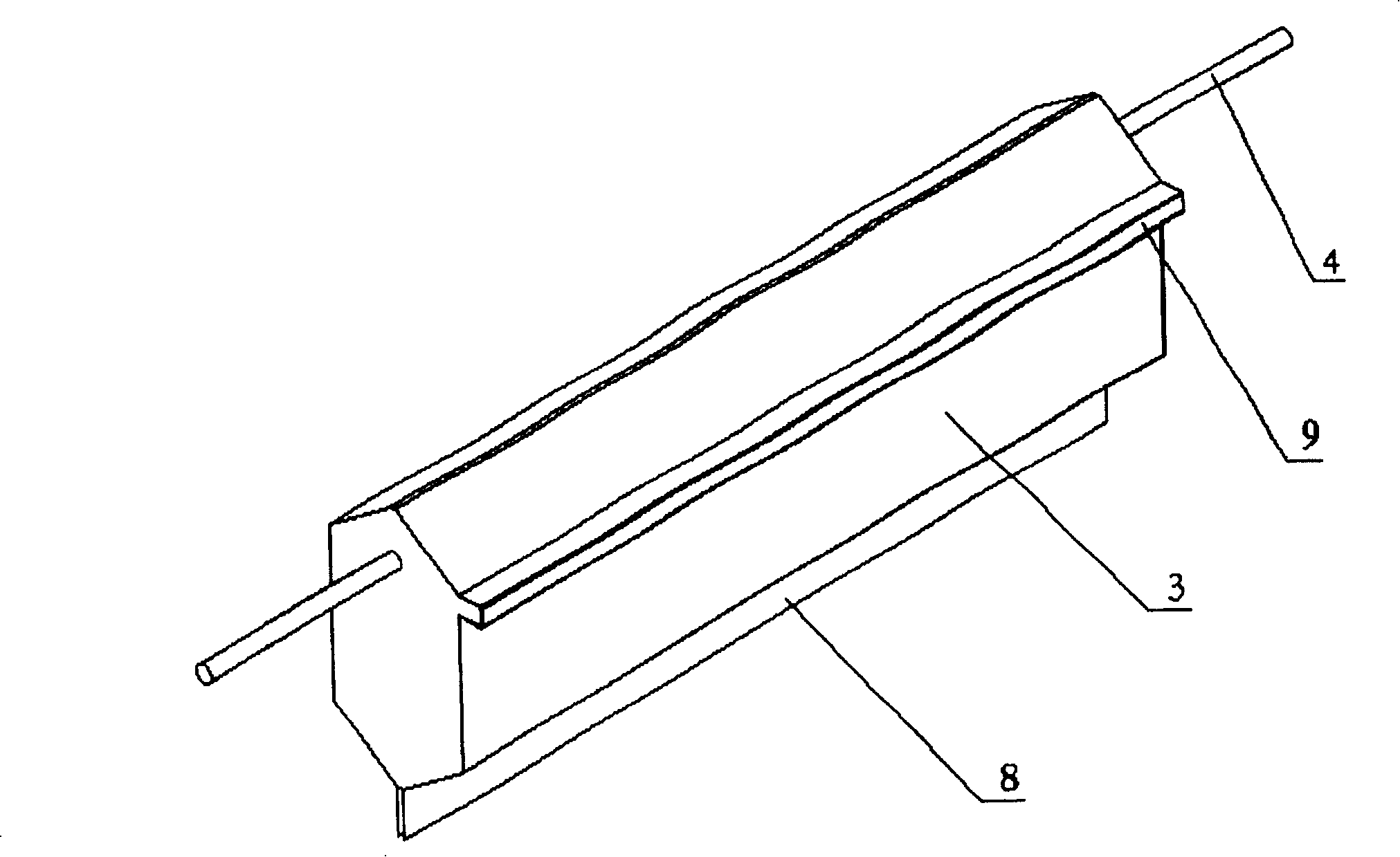

[0015] Specific embodiment one of the present invention, such as figure 1 , 2 As shown, a rotating blade type soft transmission wave hydroelectric power generation equipment includes large pontoons 1 located on both sides. The bow of the large pontoon 1 is streamlined. The distance between them is constant, and four gear transmission wheels 6 are respectively installed at symmetrical positions on the opposite sides of each large pontoon 1, such as figure 2 As shown, the transmission wheel 6 on the hull on the same side is covered with a transmission belt 2 made of rubber, steel wire and nylon mixture, and shaft holes 5 are arranged at the corresponding positions of the transmission belts 2 on both sides. The installation shaft 4 on the rotating floating boat 3 is installed on the corresponding In the corresponding shaft hole 5; the rotating pontoon 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com