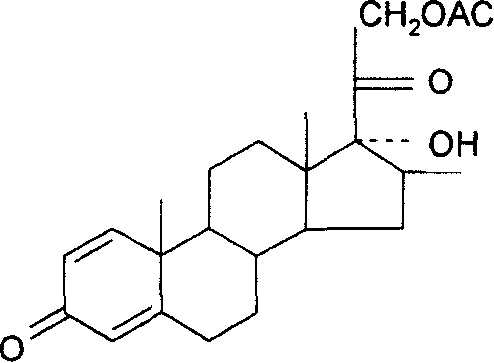

Self-emulsifying composition of beta-11 betamethasone, preparation process and application thereof

A composition and self-emulsifying technology, which are applied in the fields of self-emulsifying technology and pharmaceutical preparation, can solve problems such as low biotransformation rate of beta-12 compounds, and achieve the effects of improving biotransformation rate, simple preparation and lowering production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

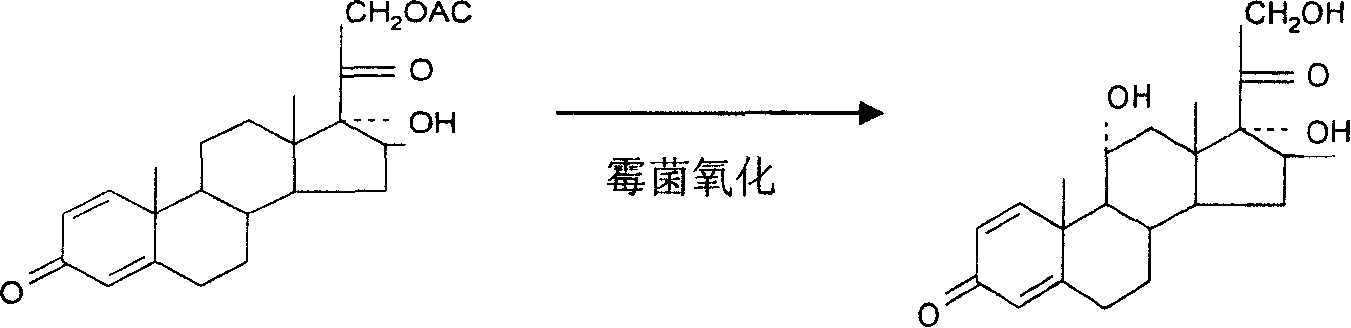

Method used

Image

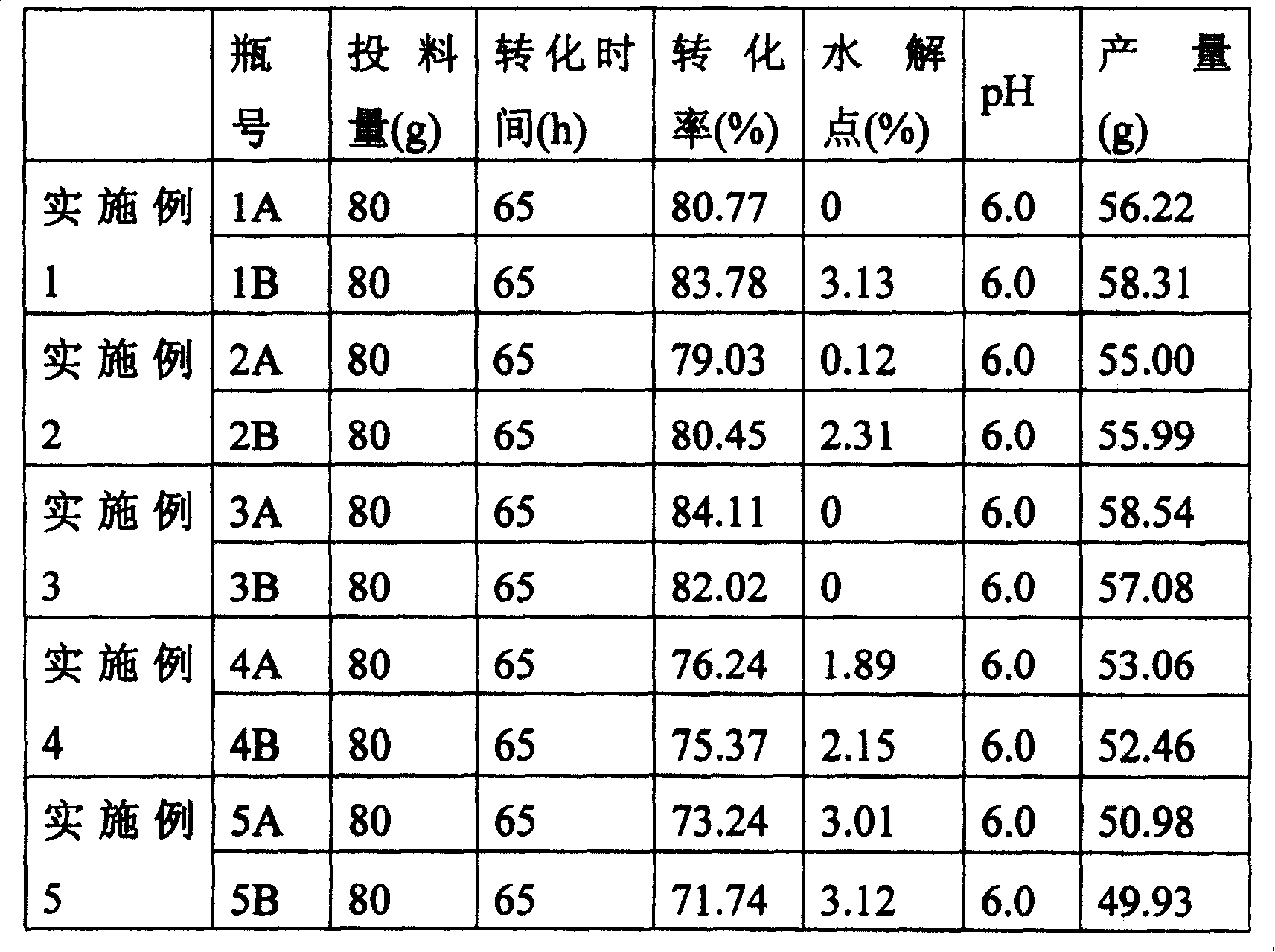

Examples

Embodiment 1

[0038] Betamethasone β-11 80g

[0039] Medium Chain Triglycerides (MCT) 150g

[0040] Absolute ethanol 130g

[0041] 1,2-propanediol 160g

[0042] Polyoxyethylene Hydrogenated Castor Oil RH40 250g

[0043] Hydroxypropyl Methyl Cellulose E15 70g

[0044] Mix the above prescription amount of substances and 80ml of foam enemy, heat, reflux at 80°C for 0.5h, add to the fermented broth where the mold (seed) has grown and transform. After being added to the fermentation broth, the average particle diameter is 200nm, and the cumulative value of 90% particle diameter is 360nm.

Embodiment 2

[0046] Betamethasone β-11 80g

[0047] Medium Chain Triglycerides (MCT) 240g

[0048] M (co-emulsifier) 200g

[0049] Tween 80 80g

[0050] Polyoxyethylene Hydrogenated Castor Oil RH40 200g

[0051] Mix the above prescription amount of substances with 80ml of foam enemy, heat, reflux at 80°C for 0.5h, add to the fermentation broth where the mold has grown and transform. After being added to the fermentation broth, the average particle diameter is 227nm, and the cumulative value of 90% particle diameter is 395nm.

Embodiment 3

[0053] Betamethasone β-11 80g

[0054] Castor Oil 230g

[0055] 1,2-propanediol 120g

[0056] Transcutol P 220g

[0057] Polyoxyethylene Hydrogenated Castor Oil RH40 250g

[0058] Mix the above prescription amount of substances with 80ml of foam enemy, heat, reflux at 80°C for 0.5h, add to the fermentation broth where the mold has grown and transform. After being added to the fermentation broth, the average particle diameter is 120nm, and the cumulative value of 90% particle diameter is 198nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com