Technological process for ultrasonic flaw detection of post insulator and porcelain bushing

A technology of pillar insulator and process method, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, instruments, and analytical materials, etc., can solve problems such as hidden dangers, and achieve the effect of preventing accidents and effective preventive measures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

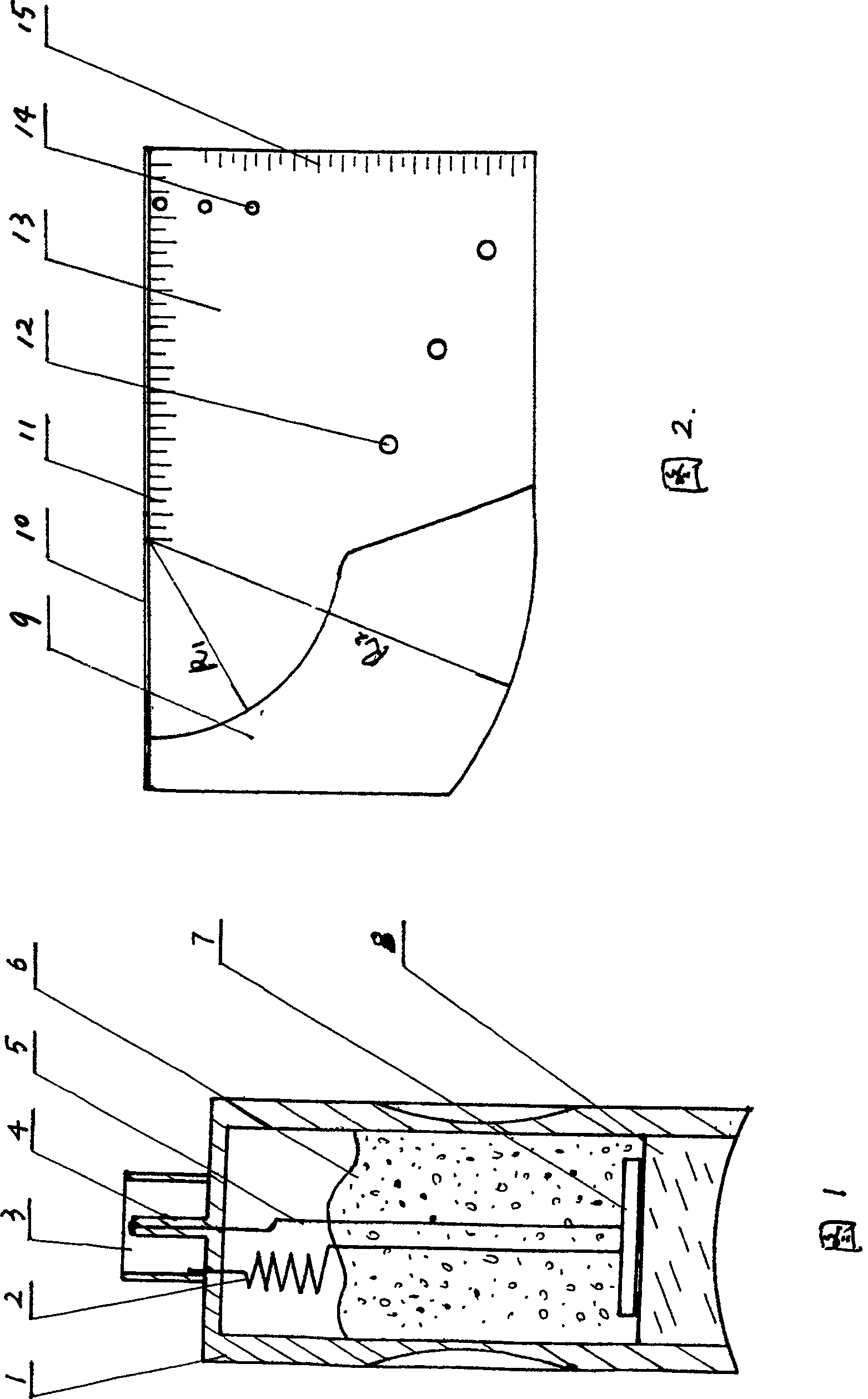

[0026] In FIG. 1 , the probe includes seven parts: housing 1 , receptacle 3 , plexiglass contact block 8 , filling material 6 , piezoelectric crystal 7 , wire 5 and coil wire 2 . It has a rectangular shell 1, one end of the shell is closed, and connected to a socket 3, the socket 3 is connected with a plug joint 4, and the other end of the shell 1 is installed with a plexiglass contact block 8; inside the shell, Adhering to the plexiglass contact block 8, the piezoelectric crystal 7 and the filling material 6 are sequentially installed with a coil wire 2 connected between the socket 3 and the piezoelectric crystal 7, and a wire is electrically connected between the plug connector 4 and the piezoelectric crystal 7 5. When in use, the socket 3 is connected to the instrument. After it is turned on, the plexiglass contact block 8 coincides with the measured object and slides, the ultrasonic wave is emitted, and is reflected back by the measured object. The single-peak waveform on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viewing angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com