Starting process of wet zinc-making system

A technology of hydrometallurgy and start-up method, which is applied in the direction of photographic process, instrument, photographic auxiliary process, etc., which can solve the problems of large gap between drive-up flow and design flow, high financial cost and start-up cost, and long start-up cycle time, etc., to achieve The driving time is short, which is conducive to the control of the driving process and the effect of fast product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

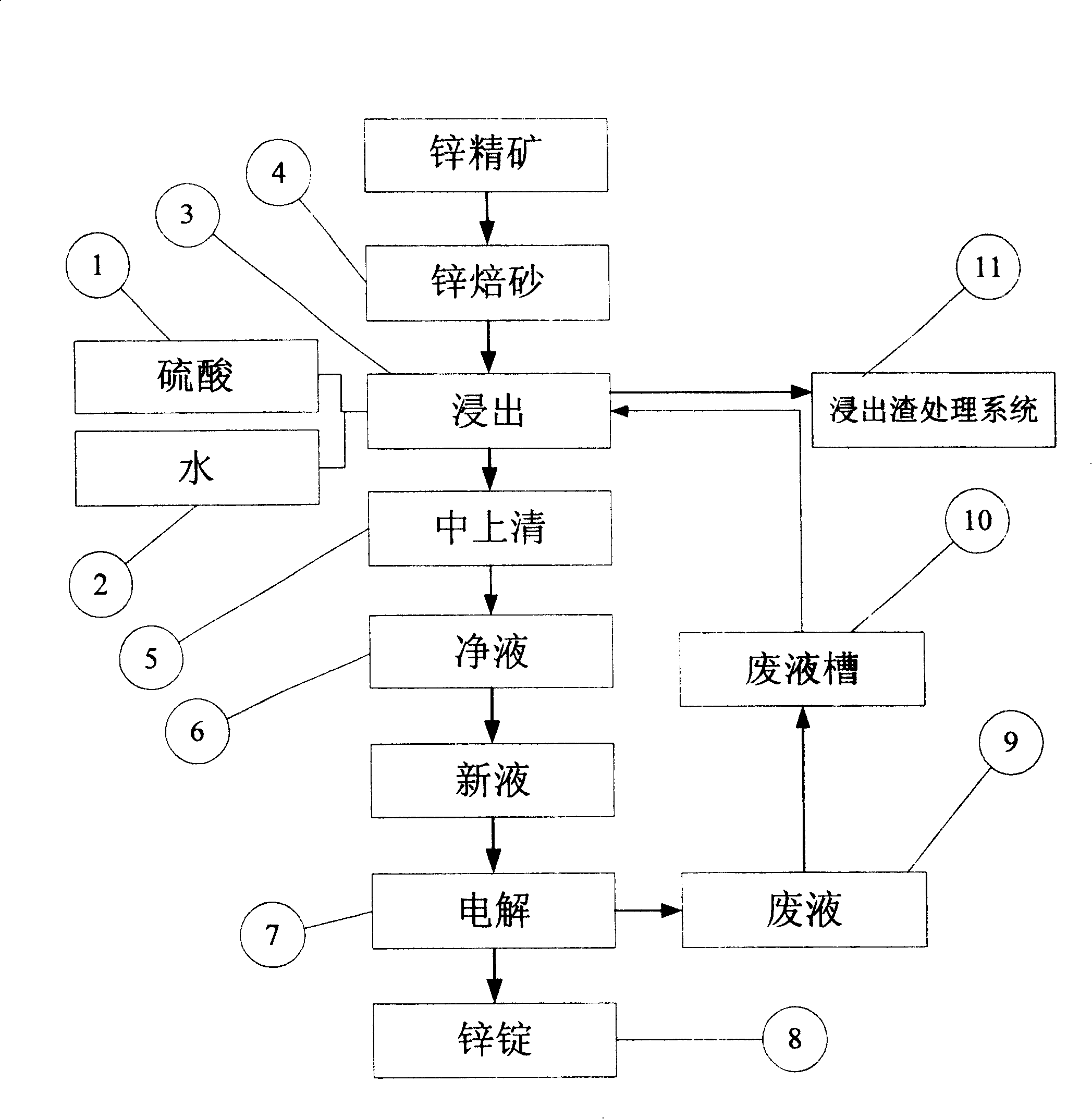

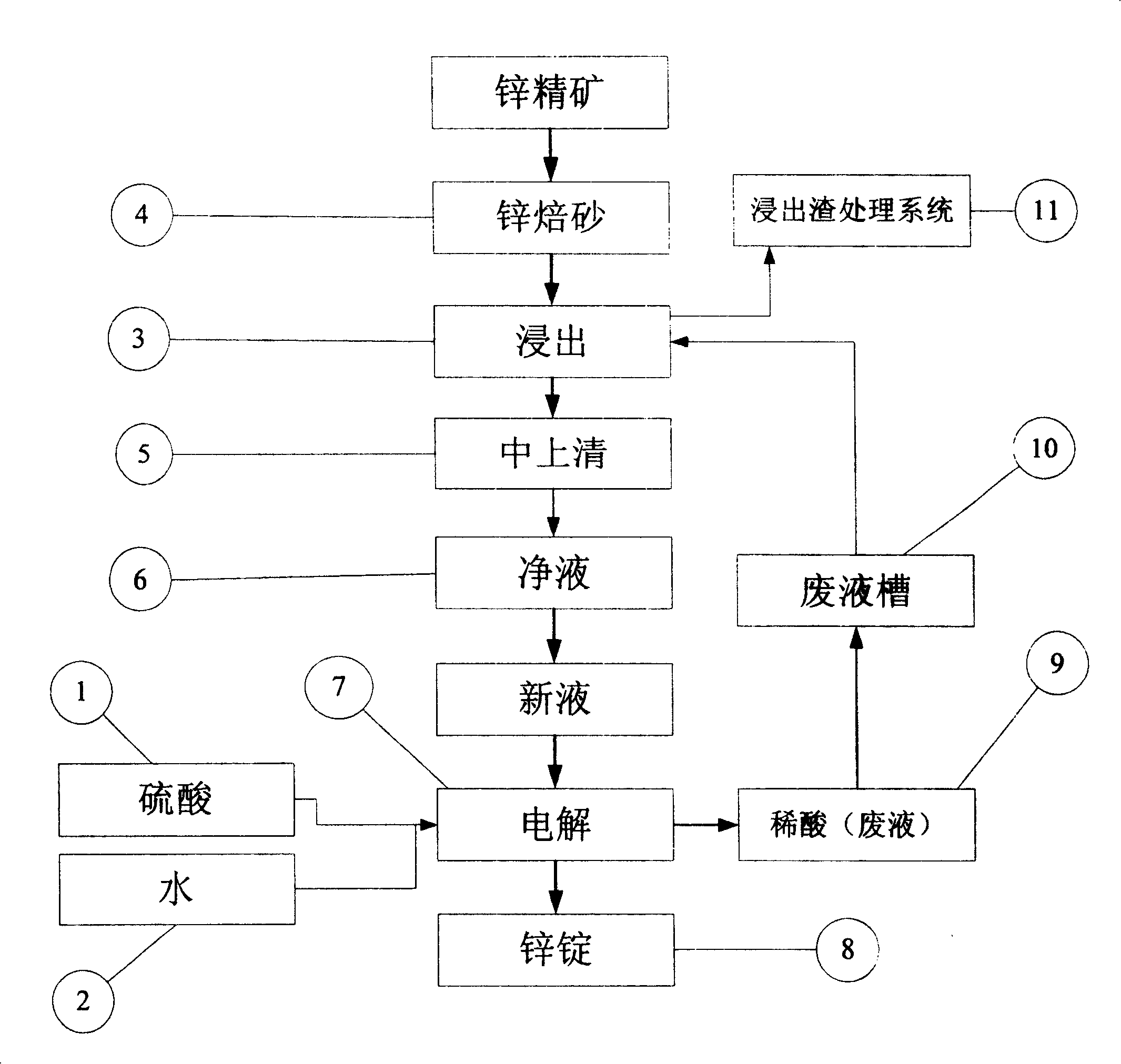

[0011] exist figure 1 In the leaching system 3, dilute sulfuric acid solution is first prepared with sulfuric acid 1 and water 2, and zinc calcined sand 4 from zinc concentrate treatment is added to produce a zinc sulfate solution containing zinc (called supernatant 5) , because the heat of reaction between sulfuric acid 1 and water 2 and the heat of reaction between sulfuric acid 1 and zinc calcined sand 4 are relatively large, the concentration of dilute sulfuric acid solution should not be too high at one time. Zinc extraction (to increase the concentration of zinc ions), according to the conditions of each system, it generally takes 3 to 4 cycles to complete the zinc extraction task of the hydrometallurgy zinc smelting system, and produce a qualified zinc sulfate solution containing zinc (supernatant 5). Sent to the clean liquid system 6, and then sent to the electrolysis system 7 after being processed by the clean liquid system 6, the product zinc ingots 8 and waste liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com