Capictance athermal flow-speed sensor based on micro mechanical technology

A flow velocity sensor, non-thermal technology, applied in fluid velocity measurement, instrument, velocity/acceleration/shock measurement, etc., can solve the problems of small range and inability to measure two-dimensional wind direction, achieve small temperature drift, improve sensitivity and resistance Interference ability, production method and simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

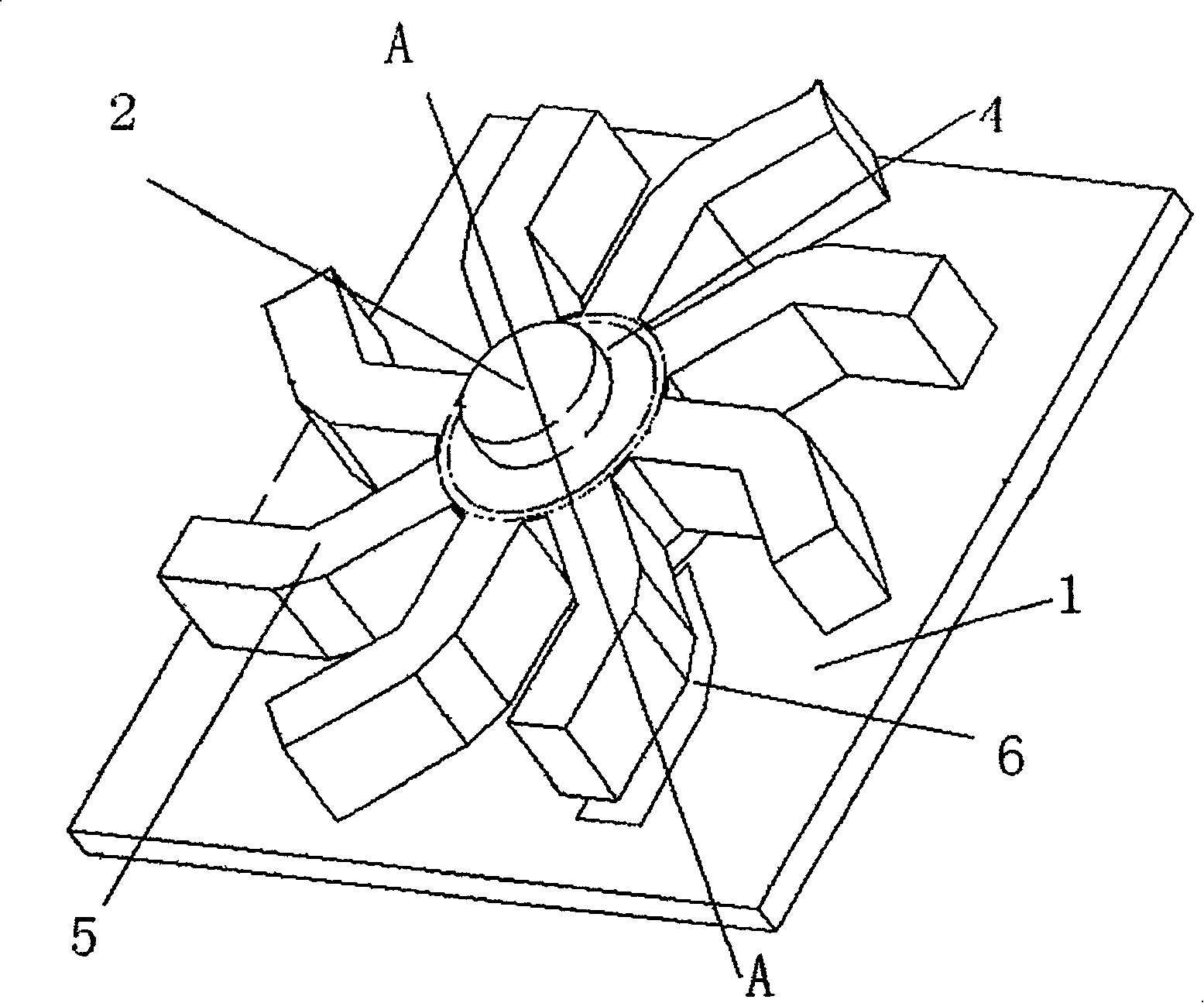

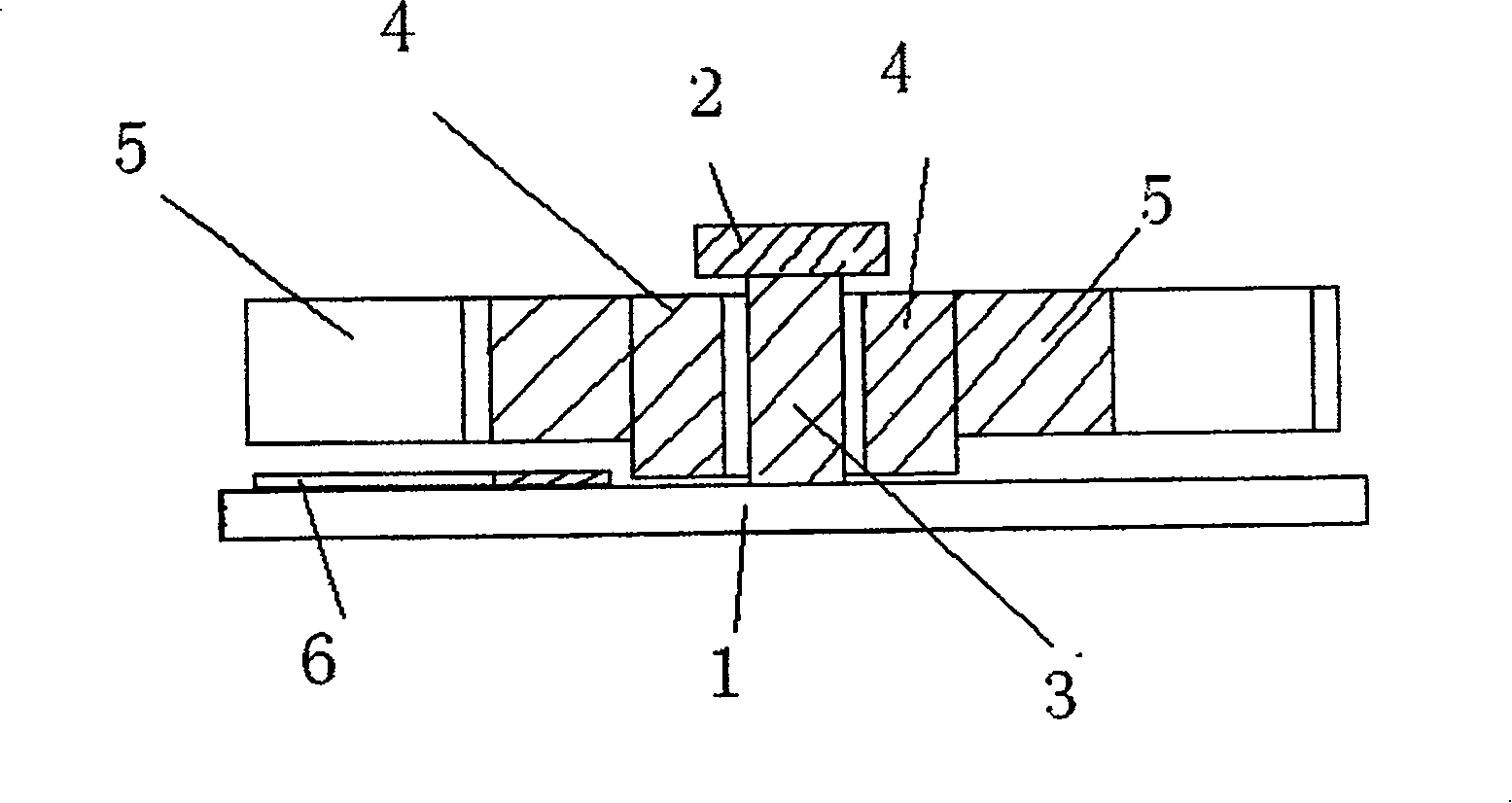

[0009] The invention is a sensor for measuring fluid velocity with an impeller structure. It consists of a glass bottom plate 1, a silicon top cover 2, a rotating shaft 3, a turntable 4, an impeller 5, a capacitor plate 6 and lead wires. The rotating shaft 3 is connected with the chassis and the top cover through a bonding process. The material of the shaft 3, the impeller 5 and the turntable 4 is conductive N-type semiconductor silicon, which is obtained by double-sided three-time etching, and a metal plate 6 is deposited on the corresponding glass surface under each impeller 5, and the impeller 5 itself conducts electricity and becomes another plate. A capacitor is formed between the conductive impeller 5 and the metal pole plate 6 . The impeller 5 relies on the contact of the rotating disk 4 and the rotating shaft 3 to lead wires from the glass base 1 . When the fluid flows through the impeller 5, it will drive the impeller 5 to rotate. The overlapping area of the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com