Thermostatic dehumidifying method and equipment

A technology of constant temperature dehumidification and finned tubes, which is applied in the field of refrigeration system design and manufacture, can solve the problems of complex system, large energy consumption, and low control precision, and achieve the effect of simple structure, good economy, and avoiding repeated consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

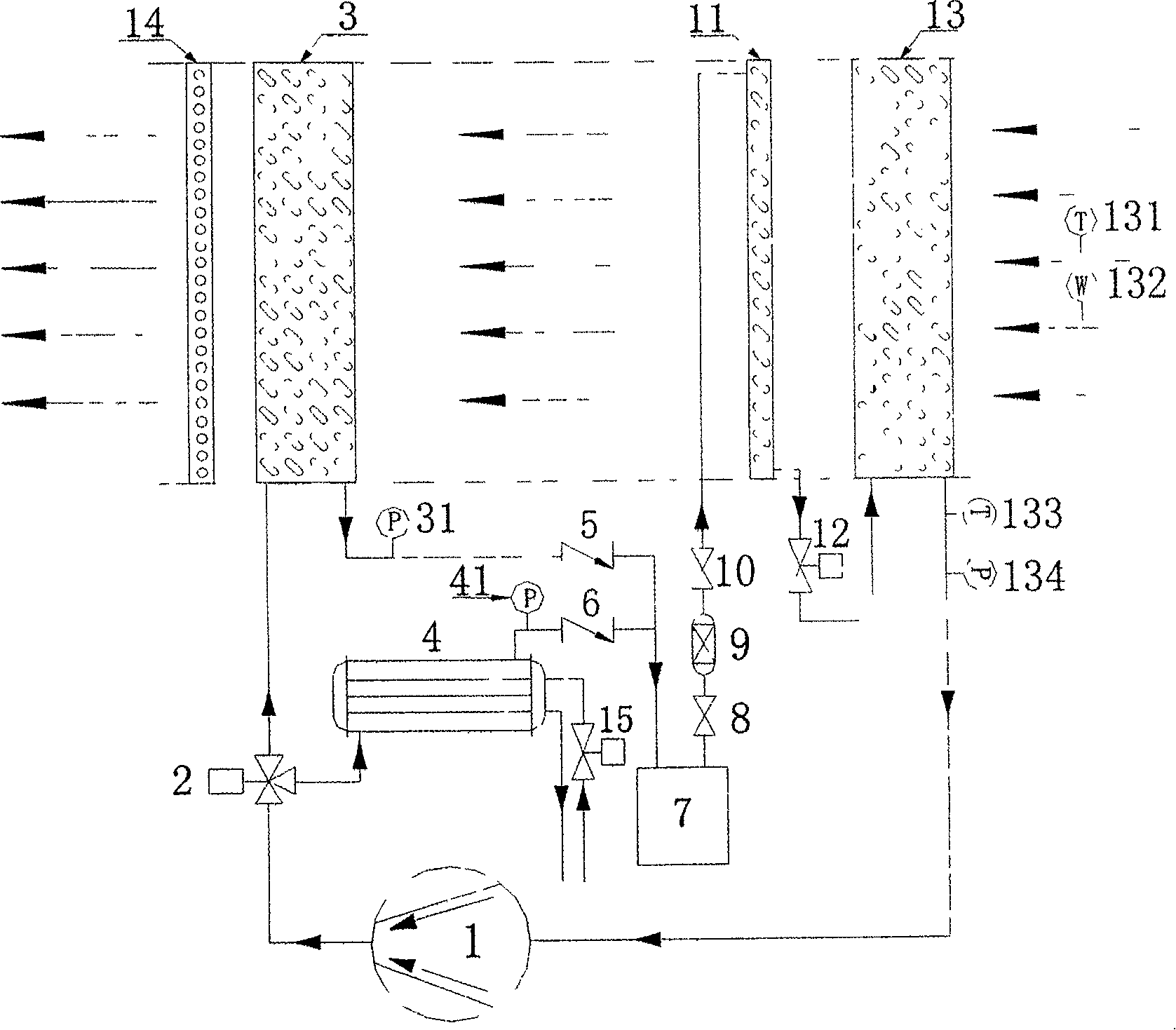

[0012] The flow chart of the constant temperature dehumidification device system is as follows: figure 1 As shown, the air inlet temperature is detected by the finned tube evaporator air inlet temperature sensor installed at the air inlet position of the device, and the air inlet humidity is detected by the finned tube evaporator inlet air humidity sensor. The input end of the variable capacity compressor 1 is connected to the output end of the finned tube evaporator 13, and the output end of the finned tube evaporator 13 is respectively connected to the finned tube condenser 3 and the The input end of the shell-and-tube heat exchanger 4, the output end of the fin-tube condenser 3 is connected to the liquid reservoir 7 through the first one-way valve 5, and the output end of the shell-and-tube heat exchanger 4 is connected through the second one-way valve 6 is connected to the liquid storage device 7, the output end of the liquid storage device 7 passes through the first shut-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com