Fuel-direct-jetting type internal combustion engine

A direct-injection internal combustion engine and fuel injection valve technology, applied in fuel injection devices, internal combustion piston engines, combustion engines, etc., can solve the problems of emission, fuel consumption rate, exhaust emission deterioration, etc., to reduce heat loss and improve flame spread , the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

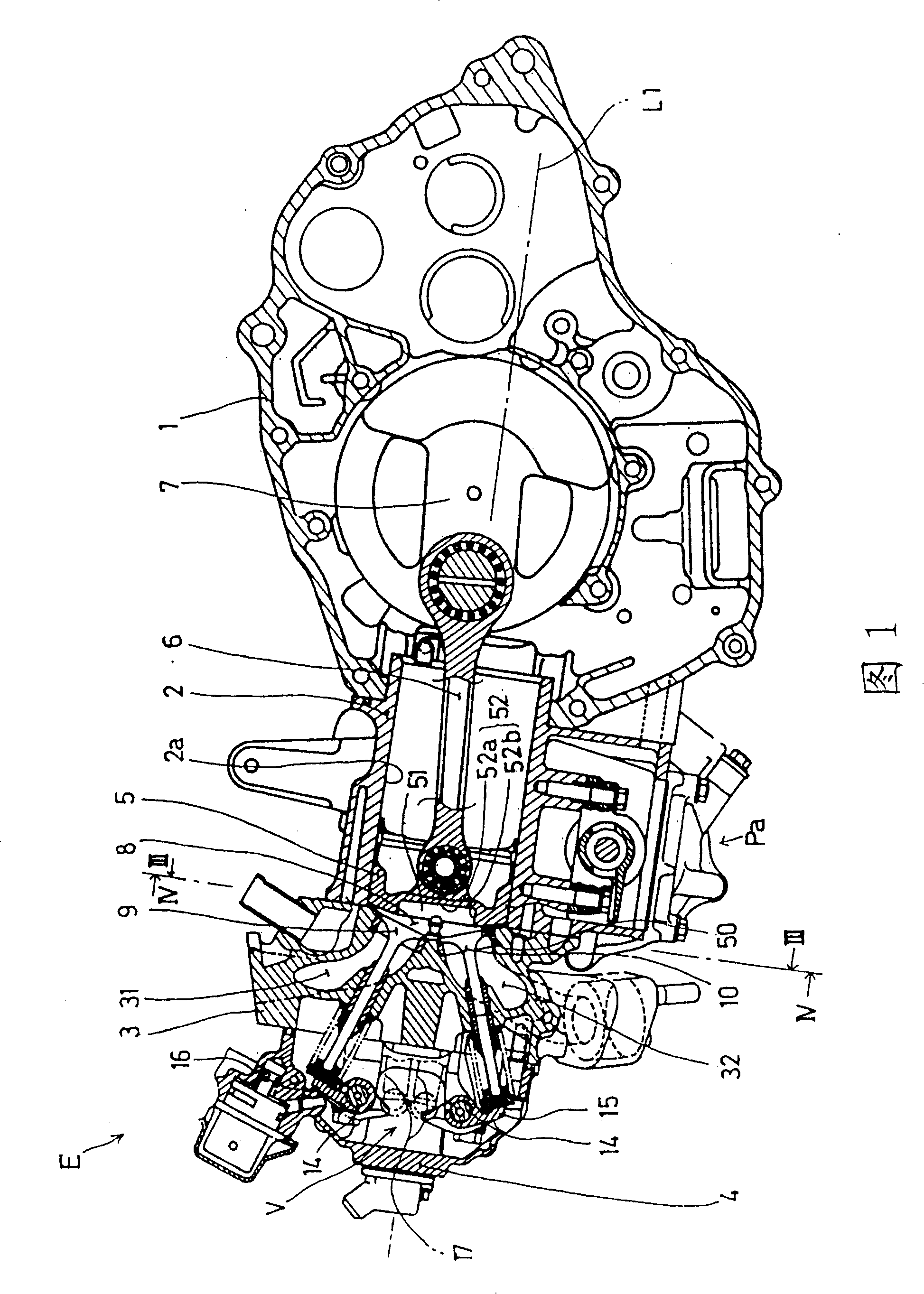

[0028] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0029] See Figure 1 and figure 2 , the fuel direct injection internal combustion engine E to which the present invention is applied is a spark ignition type four-stroke single-cylinder internal combustion engine. The internal combustion engine E includes a crankcase 1 rotatably supporting a crankshaft 7 , a cylinder 2 connected to the crankcase 1 , a cylinder head 3 connected to an upper end of the cylinder 2 , and a head cover 4 connected to the upper end of the cylinder head 3 . A piston 5 fitted in a cylinder bore 2 a of the cylinder 2 and capable of reciprocating movement rotates a crankshaft 7 through a connecting rod 6 . As shown in FIG. 1, the internal combustion engine E is mounted on the motorcycle in a state in which the cylinder 2 located at the front of the motorcycle with respect to the crankshaft 7 is slightly inclined toward the upper side of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com