Crude oil-natural gas-water three-phase flow meter and its measuring method

A technology of natural gas and flow meter, which is used in the detection of fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, etc. and other problems, to achieve the effects of reliable measurement, simplified debugging process, and expanded range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

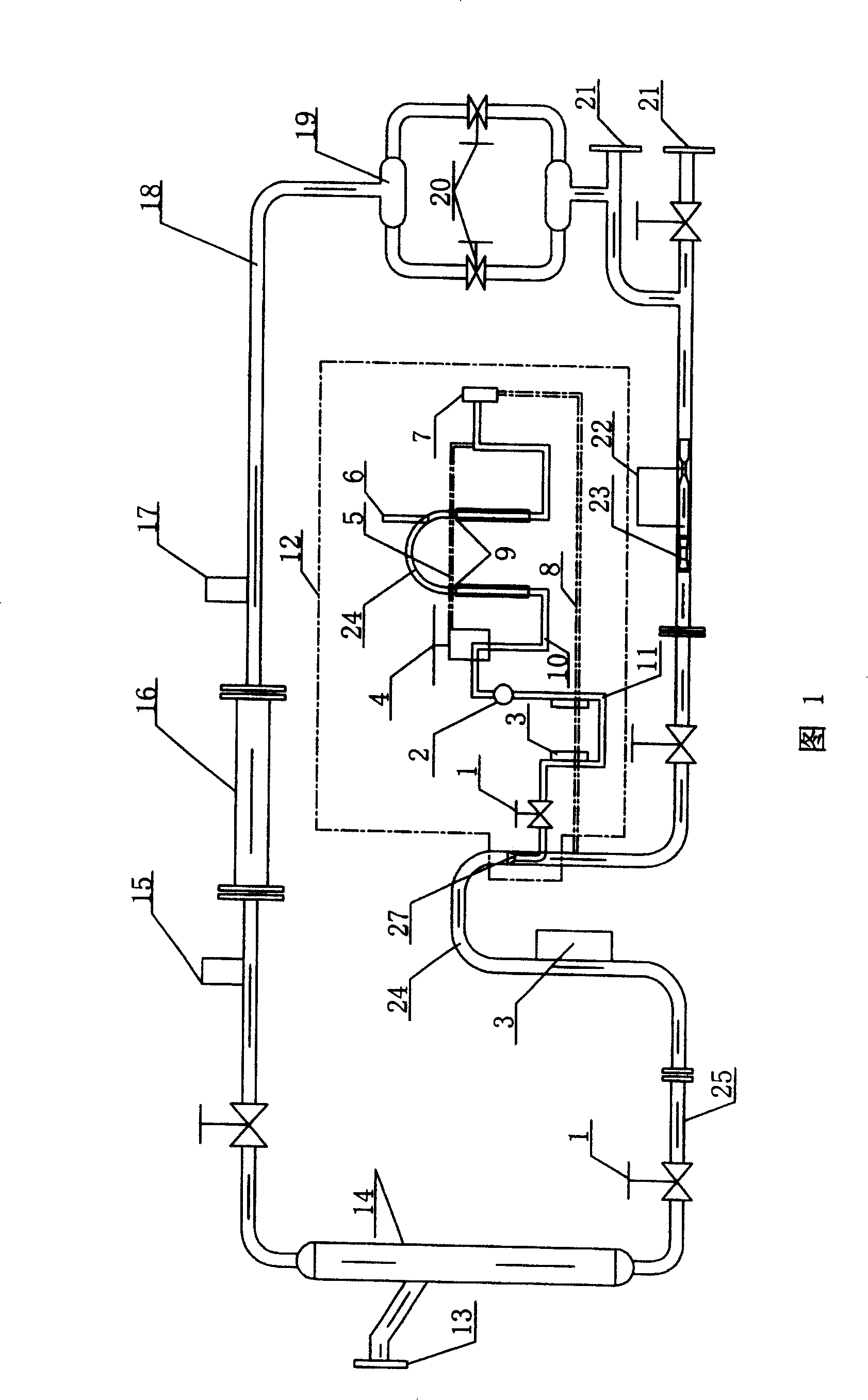

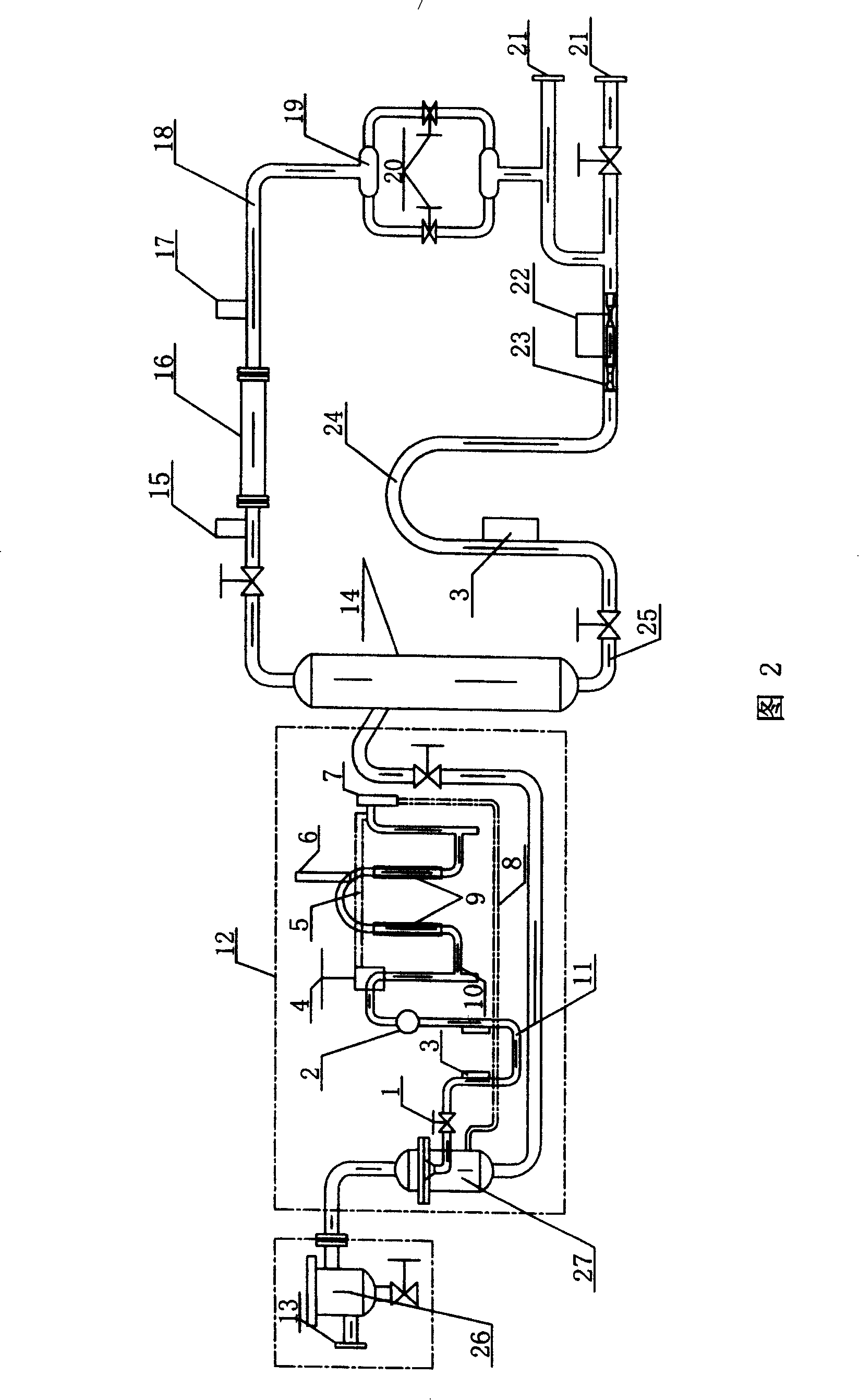

[0047] The present invention will be further described below with reference to the accompanying drawings and examples. In FIG. 1 , from the equipment inlet 13 to the discharge outlet 21 is a complete three-phase flow meter structure and working diagram. The equipment inlet 13 is divided into upper and lower two paths through the flow type finishing device 14, the upper one is the gas pipeline 18, and the lower one is the water oil pipeline 25. Among them, in the stroke of the gas pipeline 18 on the upper side, the floating ball valve 1 passes through the pressure transmitter 15, the precession vortex flowmeter 16, the temperature transmitter 17, the three-way 19, two parallel gas-liquid resistance balance valves 20, the three-way 19 and the discharge outlet 21 form a loop, and this path is mainly converted into gas flow under standard conditions by measuring pressure, flow and temperature. In the stroke of the water and oil pipeline 25 on the lower side, the floating ball valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com