Rubber asphalt compacting technology based on pavement quality indicator

A non-nuclear density meter and rubber asphalt technology, which is applied in the field of non-destructive testing, can solve the problems of rubber asphalt pavement compaction not meeting the design requirements, early damage to the pavement, and unguaranteed construction quality, so as to avoid insufficient compaction or excessive rolling, low detection cost, and the effect of saving construction machinery shifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] When the present invention is put into production, carry out according to the following steps:

[0029] 1) Calibration of non-nuclear density meter;

[0030] a) After the paving of each surface layer of the rubber asphalt pavement test road is completed and passed the inspection, 5 points are evenly selected and marked;

[0031] b) Start the non-nuclear density meter, set the representative value of the rubber asphalt surface layer thickness to be detected, and measure the density at the marked points in step a);

[0032] c) After step b) is completed, immediately drill the core sample at the corresponding position, and mark it well, and the mark corresponds to the number of the detection data of the non-nuclear density meter;

[0033] D) the core sample of step c) is drilled to measure the gross volume density of each core sample by surface dry method indoors;

[0034] e) taking step b) the measured density of the non-nuclear density meter as the abscissa, and taking...

Embodiment 2

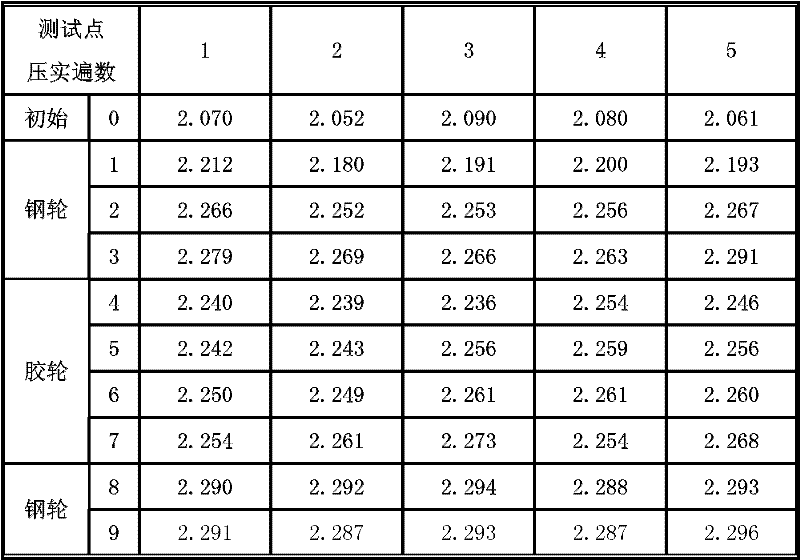

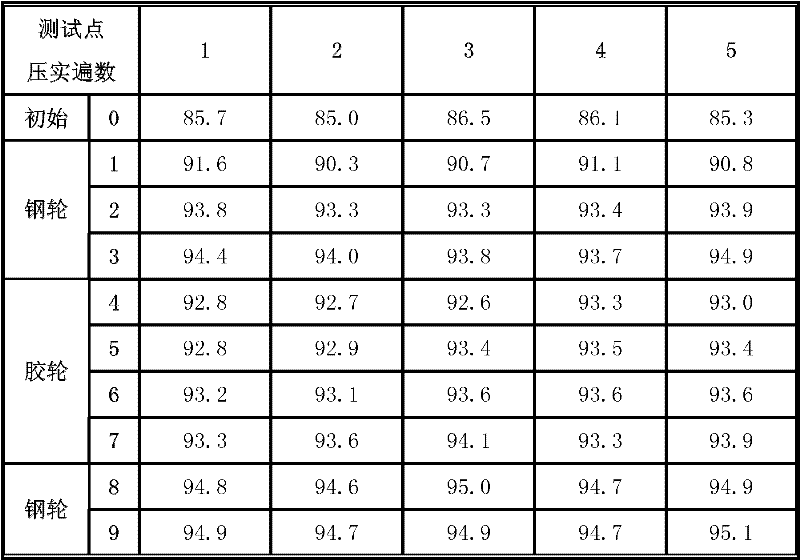

[0040] In the rubber asphalt pavement test section of Guangdong Xingyu Expressway, when the present invention was put into the test, the following steps were carried out:

[0041] 1) Calibration of PQI non-nuclear density meter;

[0042] a) After the paving of each surface layer of the rubber asphalt pavement test road is completed and passed the inspection, 5 points are evenly selected and marked;

[0043] b) Start the PQI non-nuclear density meter, set the representative value of the rubber asphalt surface layer thickness to be detected, and measure the density at the marked points in step a);

[0044] c) After step b) is completed, immediately drill the core sample at the corresponding position and mark it, which corresponds to the PQI non-nuclear density meter detection data number;

[0045] D) the core sample of step c) is drilled to measure the gross volume density of each core sample by surface dry method indoors;

[0046] e) taking step b) the measured density of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com