High pressure nano vapor generation method and generator therefor

A steam generator technology, applied in the field of steam generators, can solve problems such as long heating time, large water consumption, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

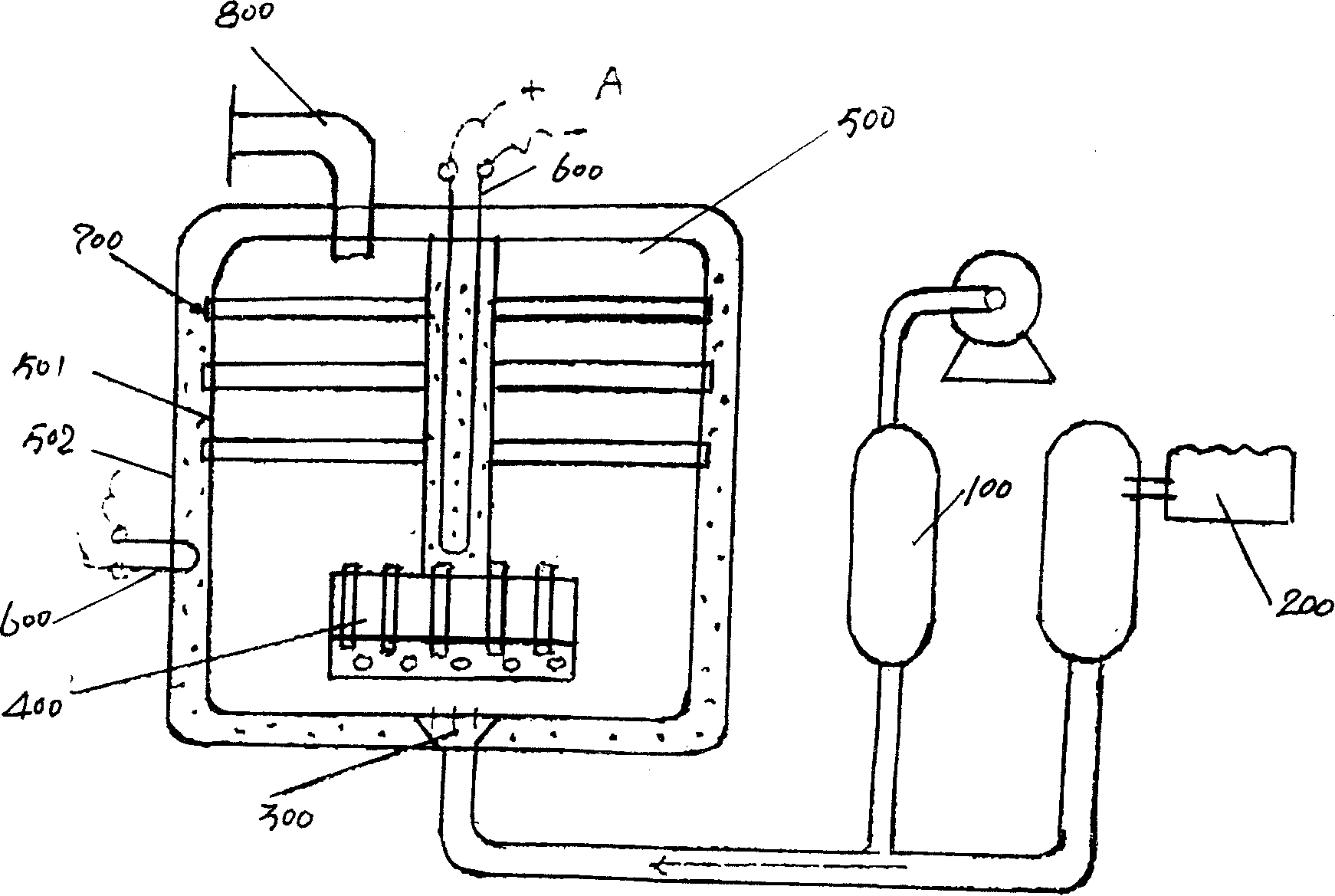

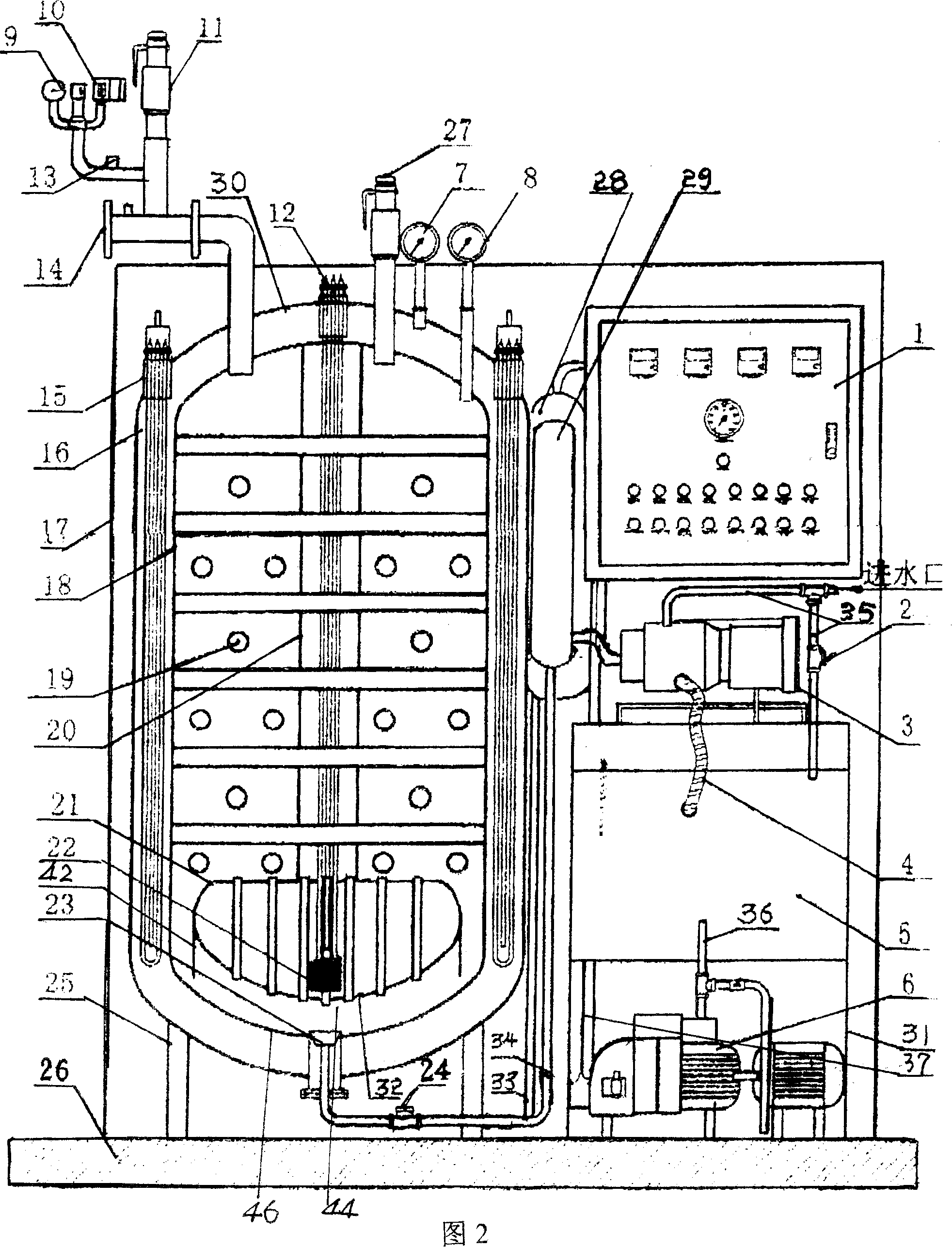

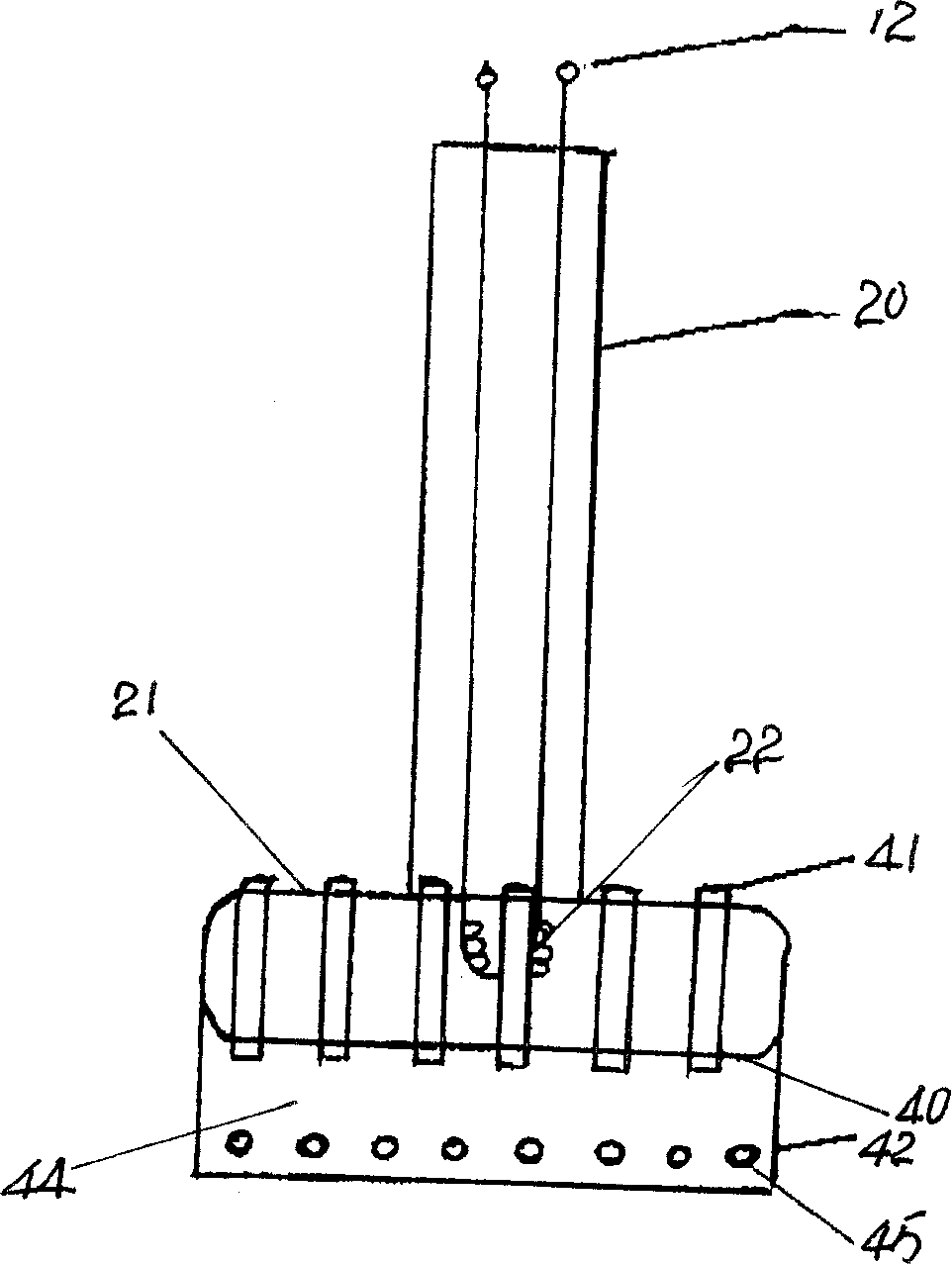

[0011] The method for generating high-pressure nano-water vapor of the present embodiment is as follows: figure 1 As shown, after the low-temperature steam or high-temperature water produced by the steam generator 100 is mixed with the pressure air produced by the air compressor 200, it is sprayed into the space 400 with rapid heating through the high-pressure nozzle 300 for ultra-fine particle atomization treatment, and the atomized Steam enters the sealed heat exchange space 500 for high-temperature heat treatment, thereby generating high-pressure nano-water vapor. The rapidly heating space 400 is provided in the heat exchange space 500 . The heat exchange space 500 includes an inner heat exchange space 501 and an outer heat exchange space 502; the inner heat exchange space 501 and the outer heat exchange space 502 are provided with an electric heating device 600; the inner heat exchange space 501 and the outer heat exchange space 502 are provided with heating oil 700. A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com