Fermentation stopping tank for palm fruit bundle and fermentation stopping and fruit threshing system

A technology of palm fruit bundles and fermentation tanks, which is applied in the direction of fat production, fat oil/fat production, etc., which can solve the problems of large investment, complex structure of the fermentation and fruit removal system, and various equipment, so as to achieve simple overall structure and reduce production equipment and plant area, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

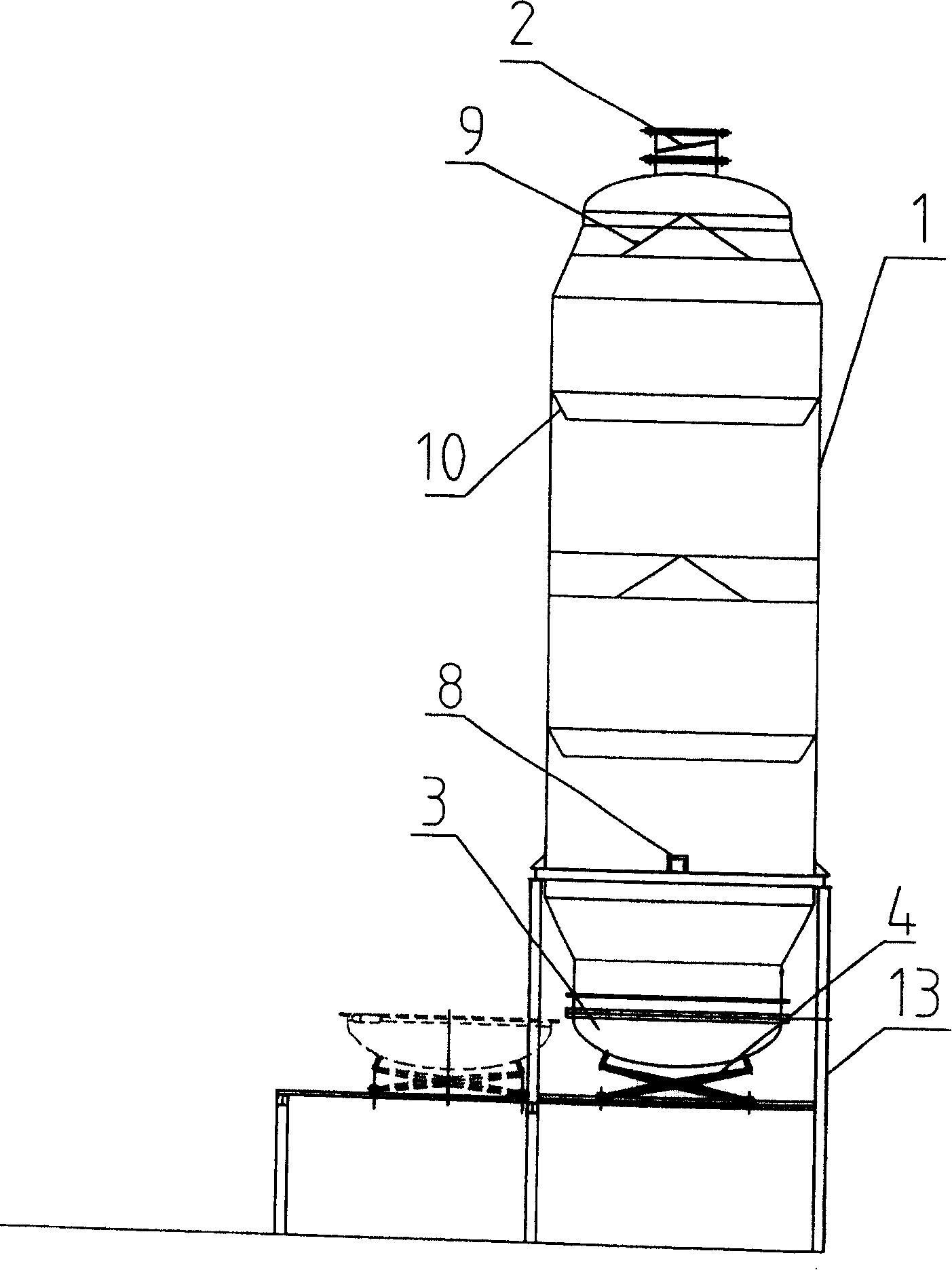

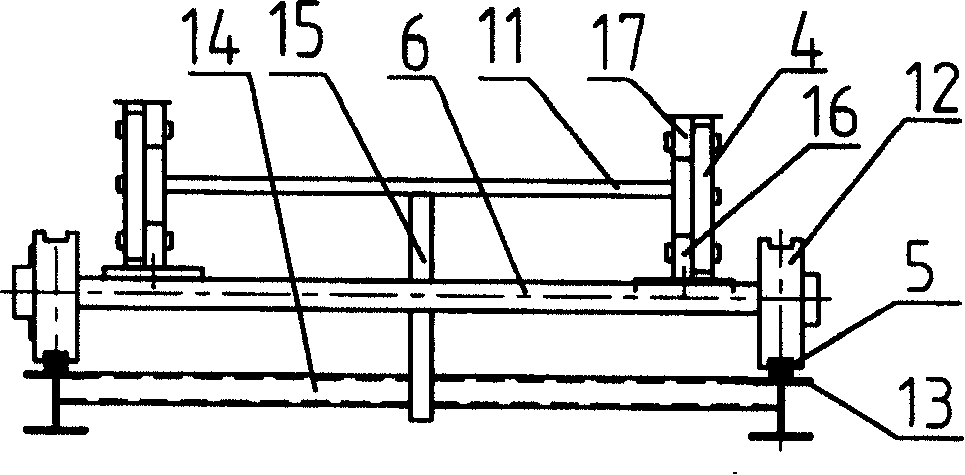

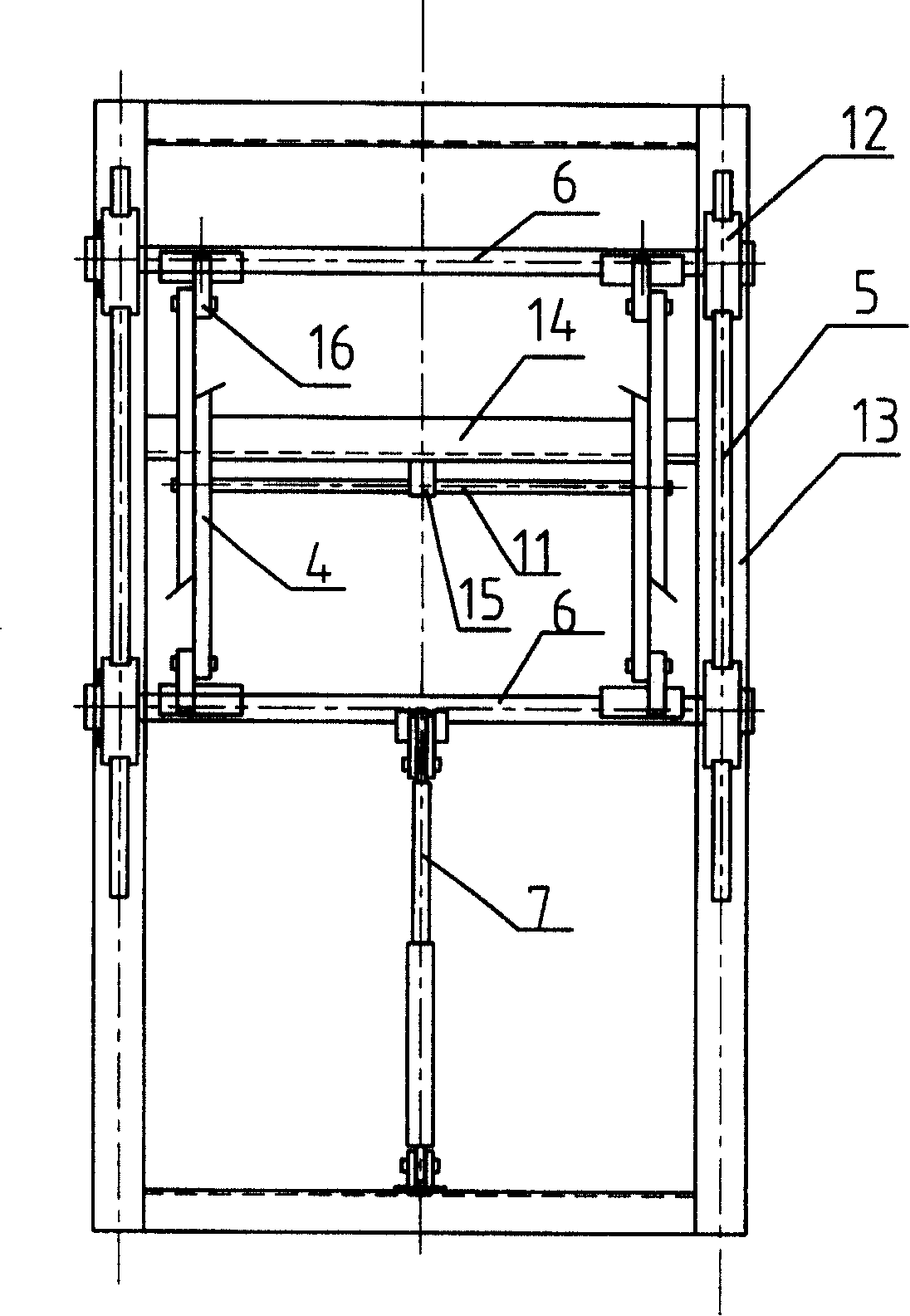

[0024] Embodiment 1, palm fruit bundle fermenter tank, tank body 1 is vertical, tank body top feed inlet is provided with automatic feed valve 2, and tank body bottom outlet is provided with opening and closing door 3, and opening and closing door 3 is with the tank. The vertical downward opening door with nested connection. The lower part of the opening and closing door 3 is provided with a lifting and translation mechanism of the opening and closing door. The lifting and translation mechanism of the opening and closing door includes two pairs of supporting rods 4 that are hinged to the front and rear sides of the bottom of the opening and closing door 3. The middle of the two pairs of supporting rods 4 is hinged on the Hinge shaft 11 two ends, the same end support bar 4 lower ends are hinged with the roller shaft 6 that roller 12 is installed on both sides, and roller 12 rolls with guide rail 5 and touches, and left side roller shaft 6 is connected with oil cylinder piston 7....

Embodiment 2

[0025] Embodiment 2. In this embodiment, the outlet at the bottom of the tank is not equipped with a vertical opening and closing door and its lifting and translation mechanism, but a horizontal opening gate valve 18 is installed, and the outer end of the gate valve is connected to a cylinder piston 19 to open and close the tank body. exit. 20 is the tank support. Others are the same as embodiment 1.

Embodiment 3

[0026] Embodiment 3, palm fruit bundle brake fermentation fruit removal system, comprising successively fruit loading platform 21, first conveyor 22, brake fermentation tank 23, temporary storage bucket 24, second conveyor 25, fruit removing machine 26, fruit loading platform The outlet of 21 is connected with the inlet of the first conveyor 22, the outlet of the first conveyor 22 is connected with the feed port of the brake fermentation tank 23, the outlet of the brake fermentation tank 23 is connected to the inlet of the second conveyor 25 through the temporary storage bucket 24, and the second conveyor The 25 exit connects the fruit stripping machine 26. The fresh fruit ears are unloaded into the fruit loading platform 21 after being measured by the truck scale, and the fruit loading platform 21 continuously enters the vertical brake fermentation tank 23 with the door open through the first conveyor 22 from the automatic valve on the top of the vertical brake fermentation ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com