Process for the purpose of determining surface evenness errors in band and particularly steel and metal band and further a surface evenness measuring roller

A technology of surface uniformity and error, applied in the field of measuring rolls for determining the surface uniformity error and surface uniformity in strips, especially steel strips and metal strips, and can solve problems such as small measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

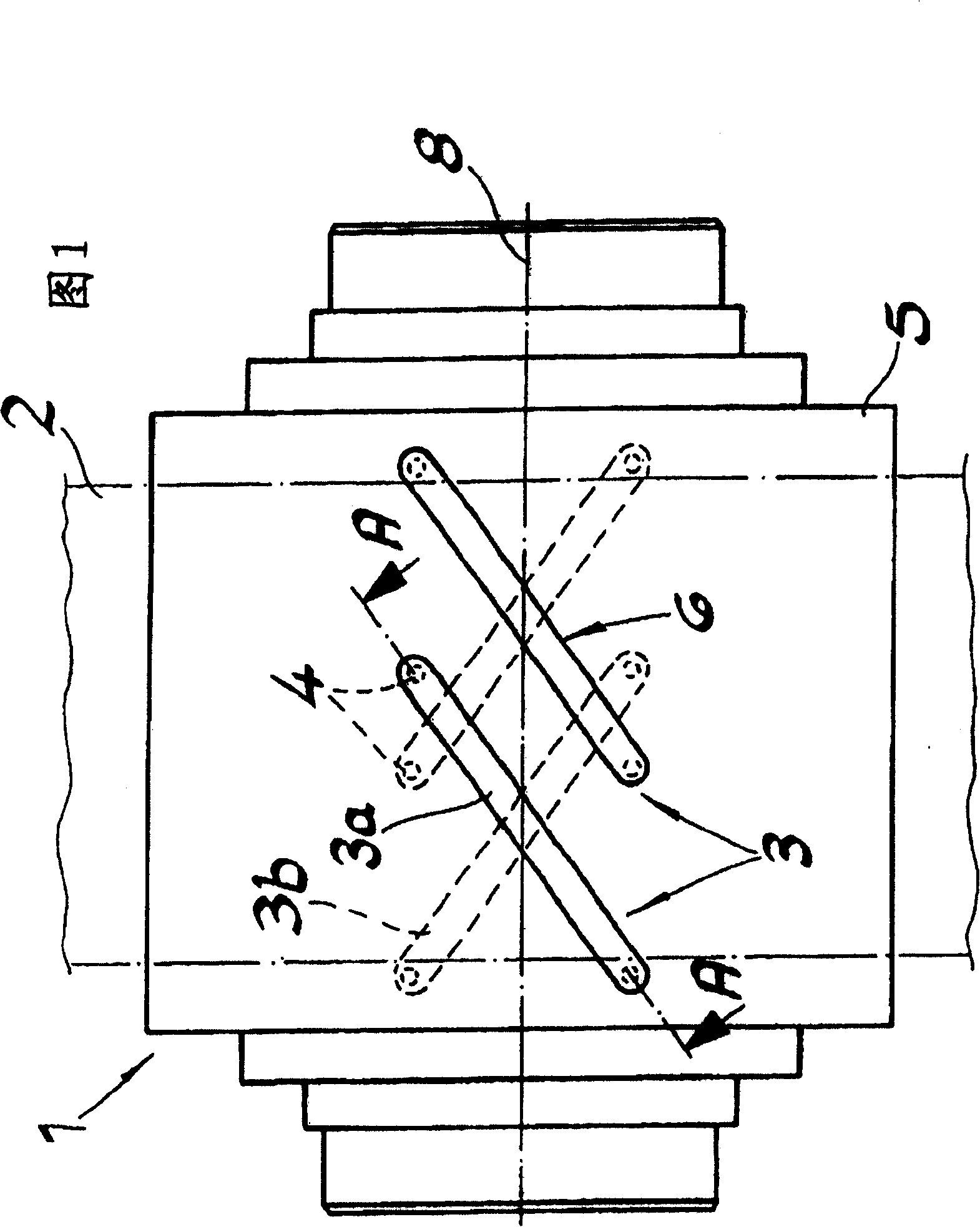

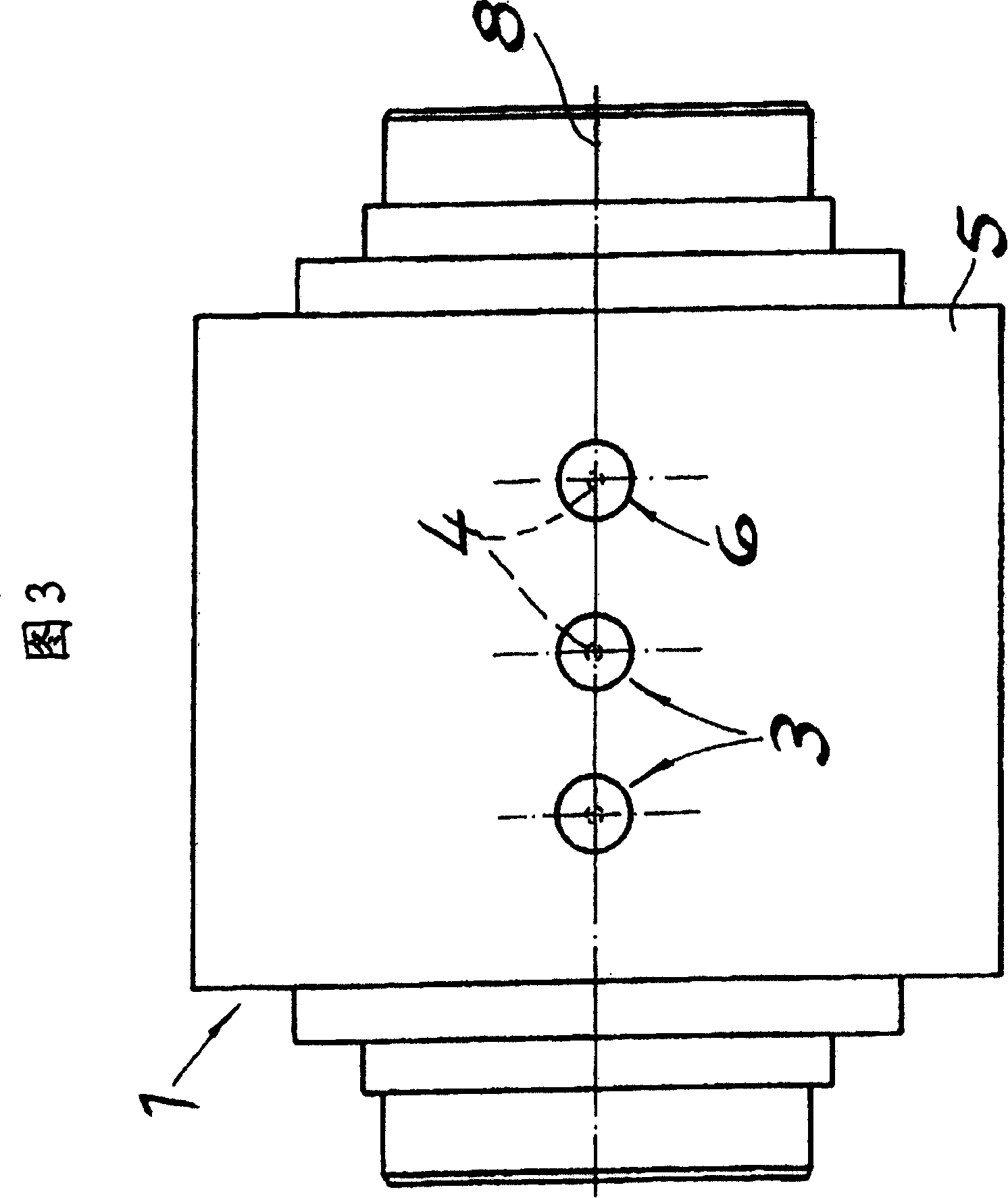

[0014] In FIGS. 1 to 4 there is shown a surface evenness sensor roll 1 for determining, in particular the steel strip and Surface uniformity errors in metal strips. Such a surface uniformity sensor roll comprises at least one measuring head 3 with two partial measuring heads joined together and offset by 180° each in the roll mantle and supported on two force transmitters and passed through A circular movement gap 6 is separated from the roll mantle 5 and fixed to each other by at least one tie rod 7, wherein the belt 2 surrounds the belt 2 with a predetermined contact arc during the measurement of the tensile stress distribution of the belt 2 over the entire belt width. around a surface uniformity sensor roller 1, thereby applying a local pressure to the surface uniformity sensor roller 1, wherein the belt 2 is subjected to tensile stress over its entire width, the local pressure corresponding to the local longitudinal tensile stress distribution in the direction of the belt,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com