Antenna connector

A technology for antenna connectors and antennas, applied to antennas, antenna supports/mounting devices, electrical components, etc., can solve problems such as inability to cope with rotational operation force, uneven torque, short elastic change stroke, etc., and achieve uniform and stable torque And the effect of positioning effect, ease of change relationship, and long change range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

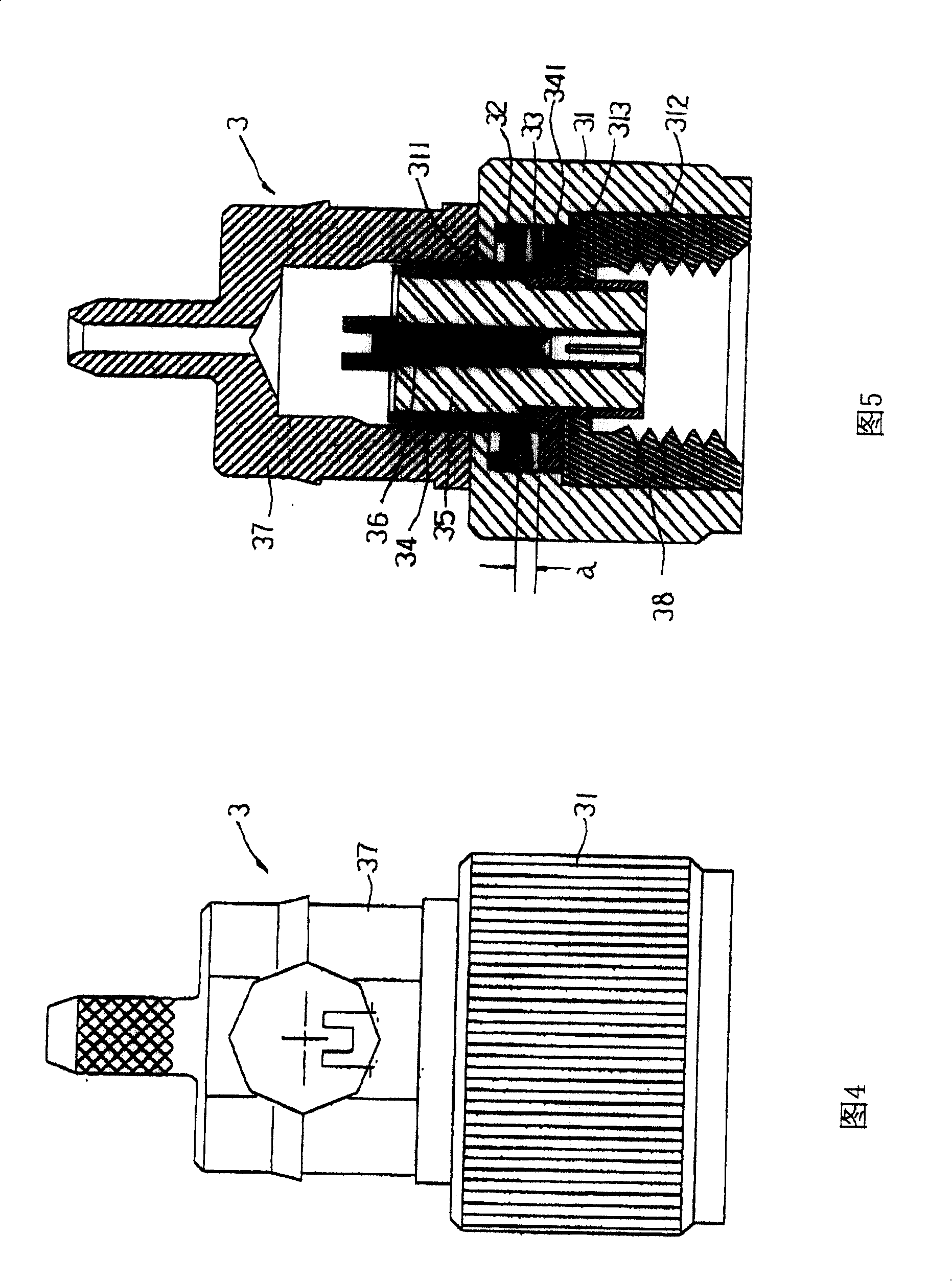

[0061]The structure, features and effects of the present invention are further described in detail in accordance with the embodiments of the accompanying drawings as follows. 6 is a side view of the antenna connector of the present invention, and FIG. 7 is a cross-sectional view of the antenna connector of the present invention.

[0062] As shown in the figure, the antenna connector 4 of the present invention includes a cylindrical shell 41, a joint assembly 42, a grounded rear cover 43, a lower gasket 44, an upper fixed washer 45, a telescopic coil spring 46, A ground connection tube 47 , an insulating sleeve 48 , and a center terminal 49 .

[0063] The inner wall of the cylindrical shell 41 has an inner shoulder 411 at about the middle portion thereof, and the interior of the cylindrical shell is divided into a lower chamber 412 and an upper chamber 413 by the inner shoulder.

[0064] The above-mentioned joint assembly 42 has a body 421 which is closely fitted to the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com