Method of extracting avenabeta glucosan

A technology for glucan and oat, applied in the field of extracting oat beta-glucan, can solve the problems of high cost, difficult removal, low product purity and the like, and achieve the effects of improved product quality, simple extraction and separation method, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, extracting β-glucan

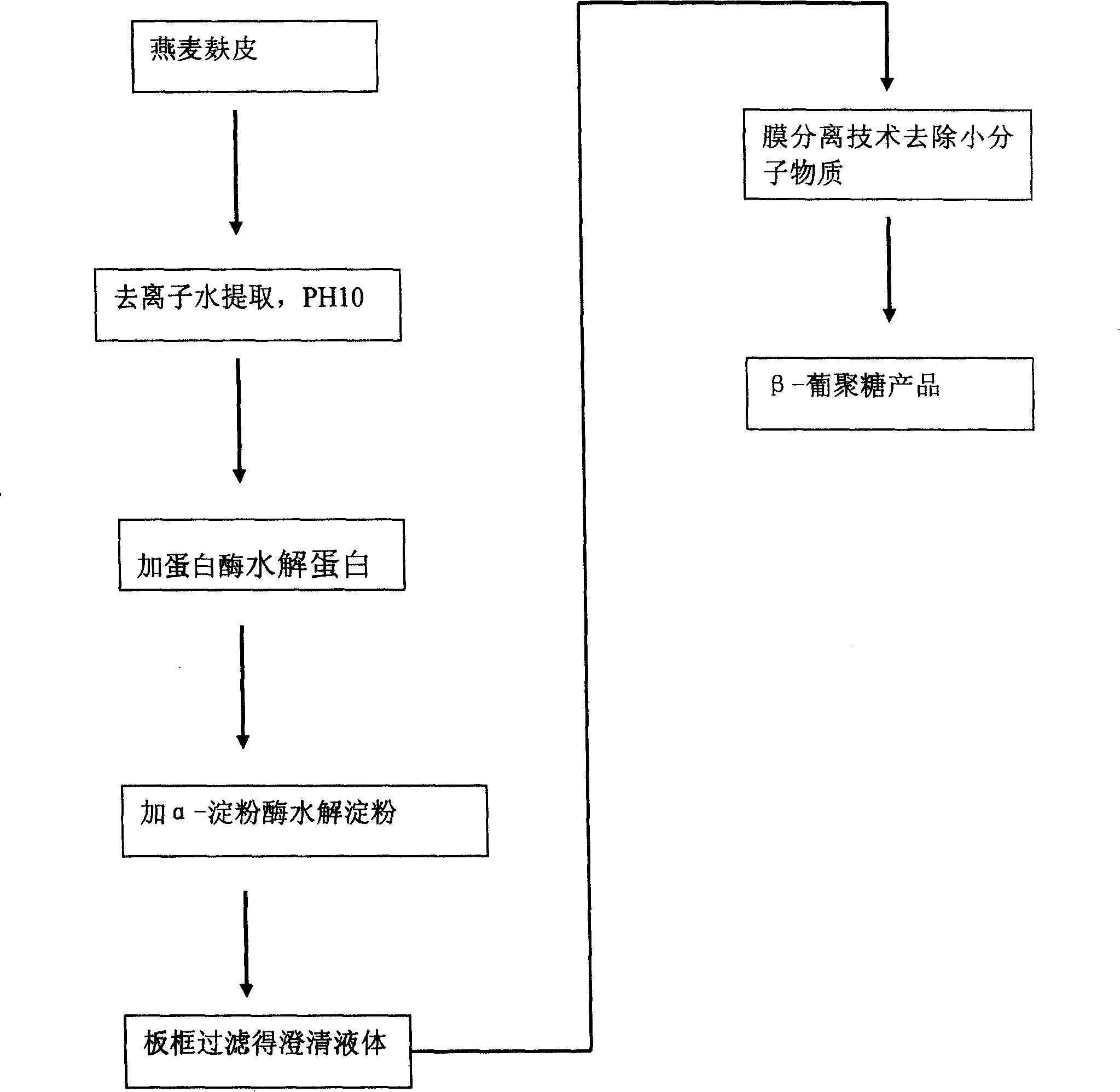

[0019] The process flow chart of extracting β-glucan is as follows: figure 1 As shown, the specific process is as follows:

[0020] (1) Selection of oat bran: oat bran between 20 mesh and 100 mesh is selected, and the content of soluble β-glucan is 8.6%.

[0021] (2) β-glucan extraction: add deionized water to the reaction vessel, adjust the pH value to about 8-10, heat to 50-60°C, add oat bran, the weight ratio of oat bran to water is 1:20 , stir evenly for 1-3 hours.

[0022] (3) Protein removal: after extraction, the pH value in the reaction vessel is about 8.0-8.5, add alkaline protease with an activity unit of 1 million U / g (use 5g alkaline protease per 100g oat bran), and continue at 50°C Stir for 1-2 hours.

[0023] (4) Starch removal: add α-amylase with an activity unit of 4000U / g (use 2g of alkaline protease per 100g of oat bran), stir at 80°C for 0.5 hours, and decompose the starch into small molecular weight oligosaccha...

Embodiment 2

[0028] Example 2, functional experiment of oat β-glucan product

[0029] 1. Moisturizing effect experiment

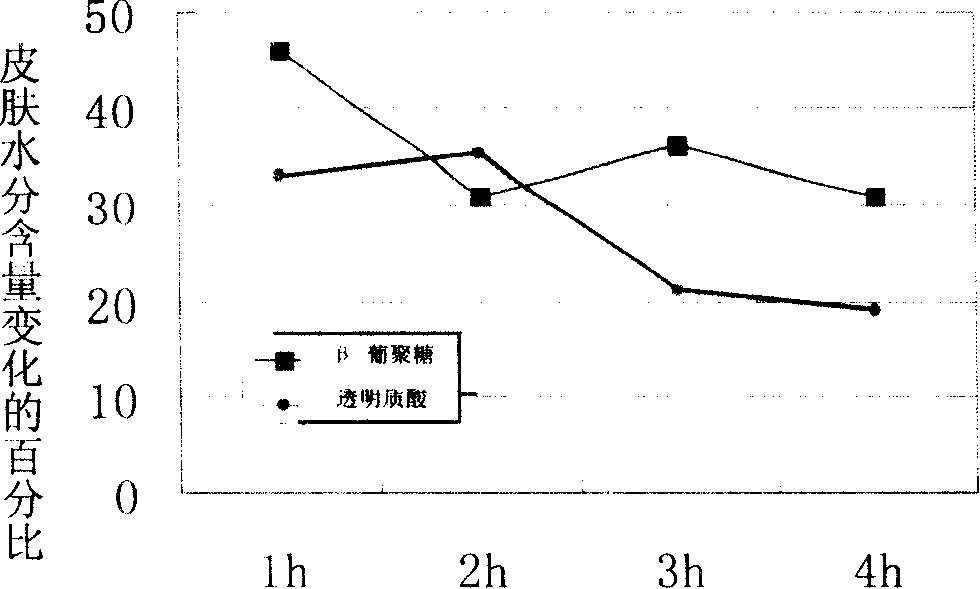

[0030] Using the human body test method, use a moisture tester to test the moisture content and TEWL value of the skin, and select 20 volunteers; the volunteers are half male and half male. Two different emulsions were applied to the skin surface: one containing 5% oat-β-glucan (β-glucan) and one containing 5% hyaluronic acid (HA); tested every half hour for a total of 4 hours. The change curve of the percentage change of the moisture content of the skin surface over time is as follows: figure 2 As shown, the results show that compared with hyaluronic acid, oat β-glucan has a better long-lasting moisturizing effect.

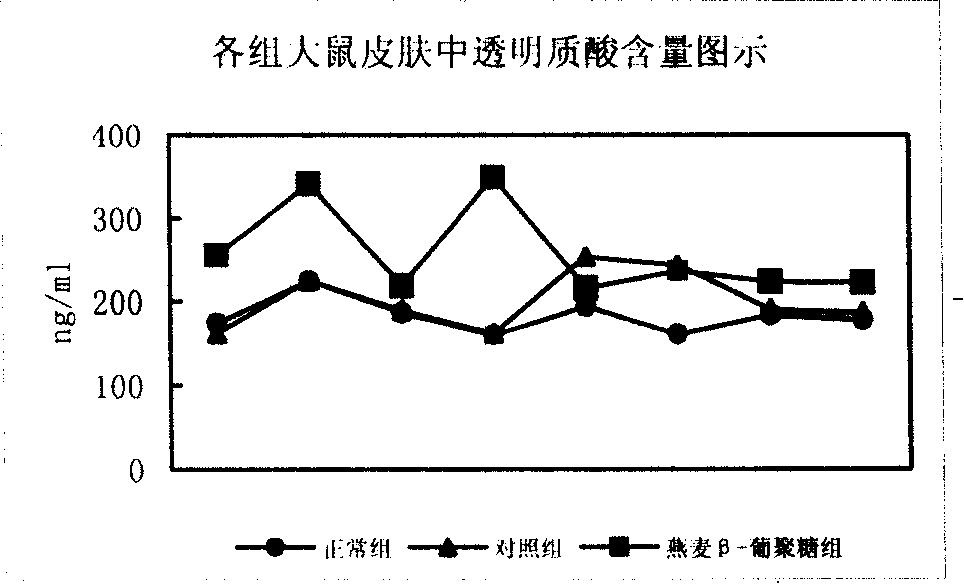

[0031] 2. Oat-β-glucan can increase the content of hyaluronic acid in rat skin

[0032] 2.1 Experimental drugs

[0033] Oat β-glucan used 1% oat β-glucan; the control group used 1% hyaluronic acid.

[0034] 2.2 Experimental animals

[0035] 40 clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com