Ribbed grid-like reinforced concrete shear wall and making method thereof

A production method and mesh-like technology, which can be applied to walls, building components, earthquake-proof and other directions, can solve the problems of poor shear stiffness and cannot be applied, and achieve the effects of large lateral stiffness, improved shear stiffness, and high shear stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

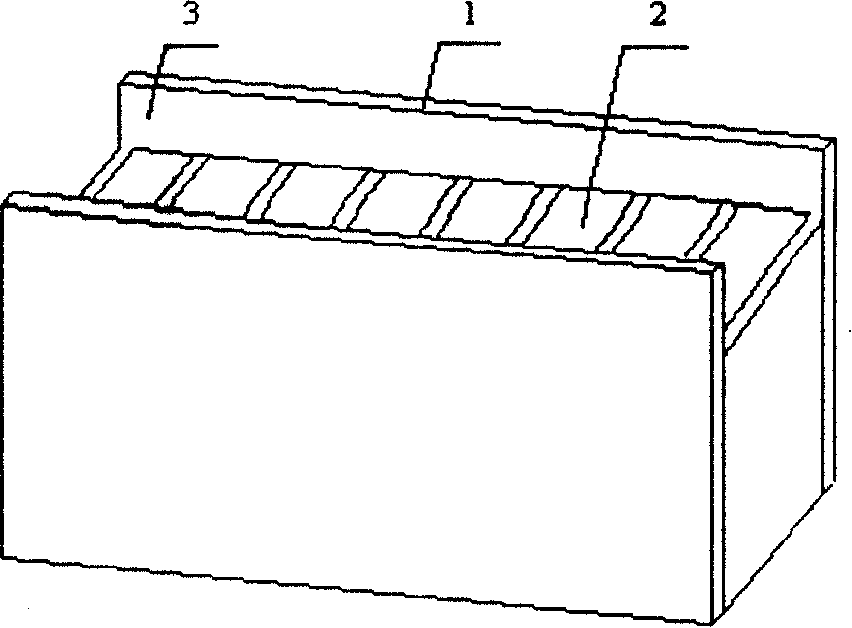

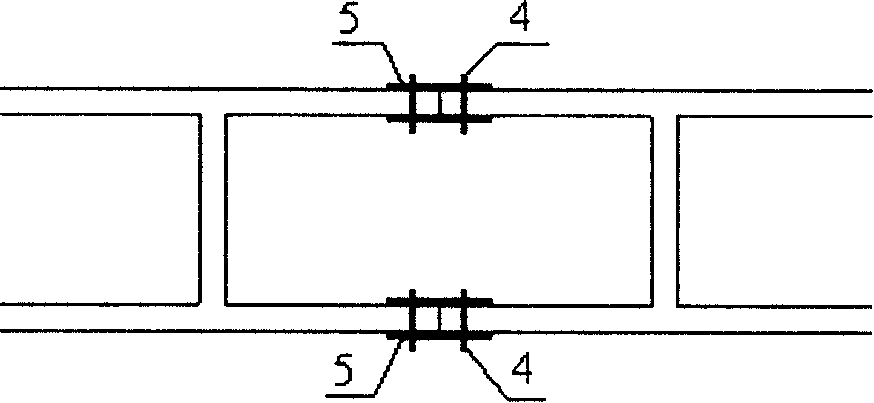

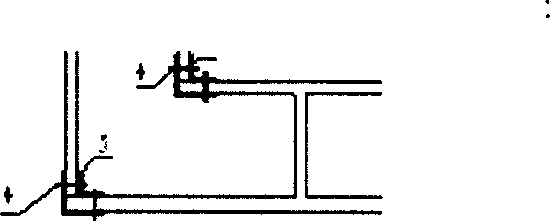

[0018] Embodiments of the present invention: as attached figure 1 Shown, the reinforced concrete shear wall of the dense rib grid pattern of the present invention is formed by layering connection of two or more cavity slabs (1), and the height of the cavity slab (1) is determined by the layer of the building. The height is determined by calculation, divided into 4 to 6 blocks along the height direction, and the height is generally controlled between 450 and 750mm; the width of the cavity slab (1) is determined by the load-bearing wall bay, generally between 7.8m and 12m The bay can be divided into two sections (3.9m ~ 6m) or three sections (2.6m ~ 4m), forming a "line-shaped connection node", forming an "L-shaped section node" at the corner of the building, and forming at the intersection of vertical and horizontal walls. "T-shaped" or "cross-shaped joints" are connected by thin steel plates (5) bent into L-shaped, straight-shaped and self-tapping screws (4); the cavity slab (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com