Water single component poly urethane woodware paint and its producing method

A one-component, polyurethane technology, applied in the field of paint, can solve the problems of large VOC volatilization, not resistant to alcohol scrubbing, easy to turn yellow, etc., to achieve the effect of reducing volatilization, environmental protection, and prolonging the time of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0032] Waterborne one-component polyurethane open-effect wood lacquer, consisting of the following components: waterborne one-component polyurethane content of 75%, water-soluble cellulose ether content of 7.5%, deionized water content of 17%, water-based silicone The content is 0.5%; the above percentage refers to the percentage containing the total mass.

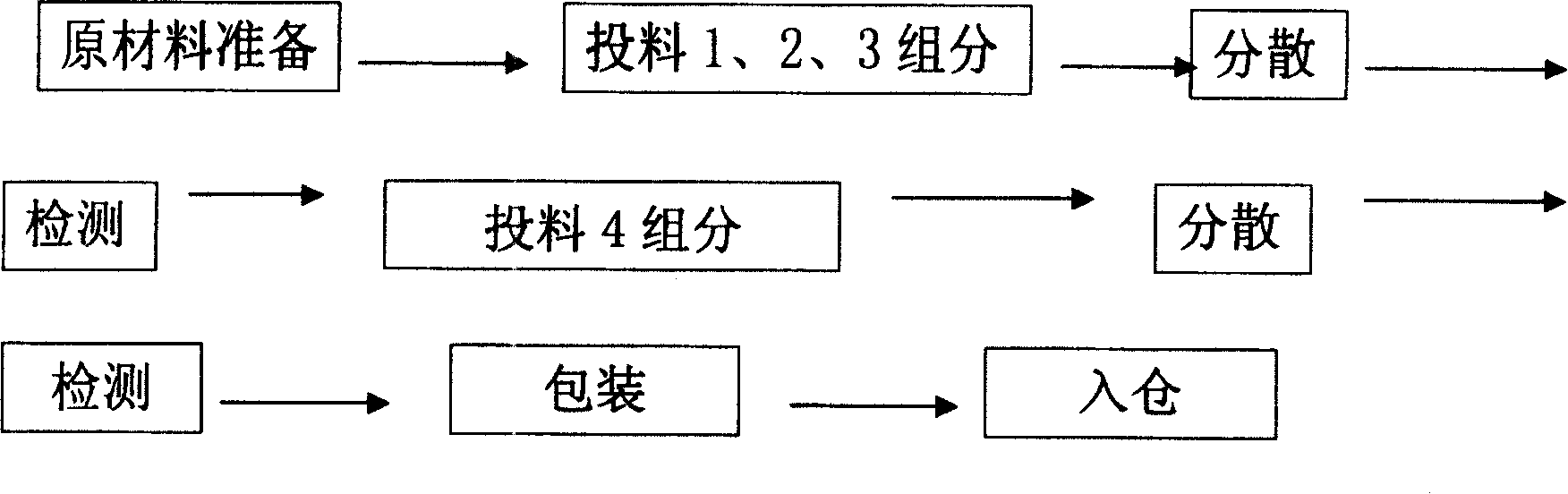

[0033] The manufacturing process adopted in this embodiment is as follows:

[0034] (1) Prepare raw materials: one-component polyurethane aqueous dispersion, water-soluble cellulose ether, water, water-based silicone;

[0035] (2) Under normal temperature conditions, put into a single-component polyurethane aqueous dispersion, water-soluble cellulose ether, and pure water by percentage in a conventional high-speed disperser to disperse, so that the fineness of the material is less than 40 microns;

[0036] (3) Control the temperature below 50°C, put water-based silicone into the disperser, and disperse at a medium speed f...

specific Embodiment 2

[0040] Fatty acid modified one-component polyurethane aqueous dispersion adopts the product of Germany Bayer (bayer), and the model is VP LS 2342, and its content is 84.5%; Water-soluble cellulose ether is the product of German Clariant Gmbh (Clariant Gmbh), and its content 2%; the content of pure water is 9.5%, and the water-based silicone is mixed by several materials of Byk028, Byk024, Byk346, and Byk381 of BYK Company in Germany, and the content is 3%; the above percentage refers to the content of percentage of the total mass.

specific Embodiment 3

[0043] The water-based one-component polyurethane open effect wood lacquer is composed of the following components: the fatty acid modified one-component polyurethane aqueous dispersion adopts the product of Bayer (bayer) company in Germany, the model is VP LS 2342, and its content is 81%; water-soluble Cellulose ether is a product of Clariant Gmbh in Germany. Its content is 4.5%, and the content of purified water is 13%. Water-based silicone is made by mixing several materials of Byk028, Byk024, Byk346, and Byk381 of BYK Company in Germany. , the content is 1.5%; the above percentages refer to the percentages containing the total mass. The result obtained by the experiment shows that the performance of the product obtained in embodiment 3 is better than that in embodiments 1 and 2.

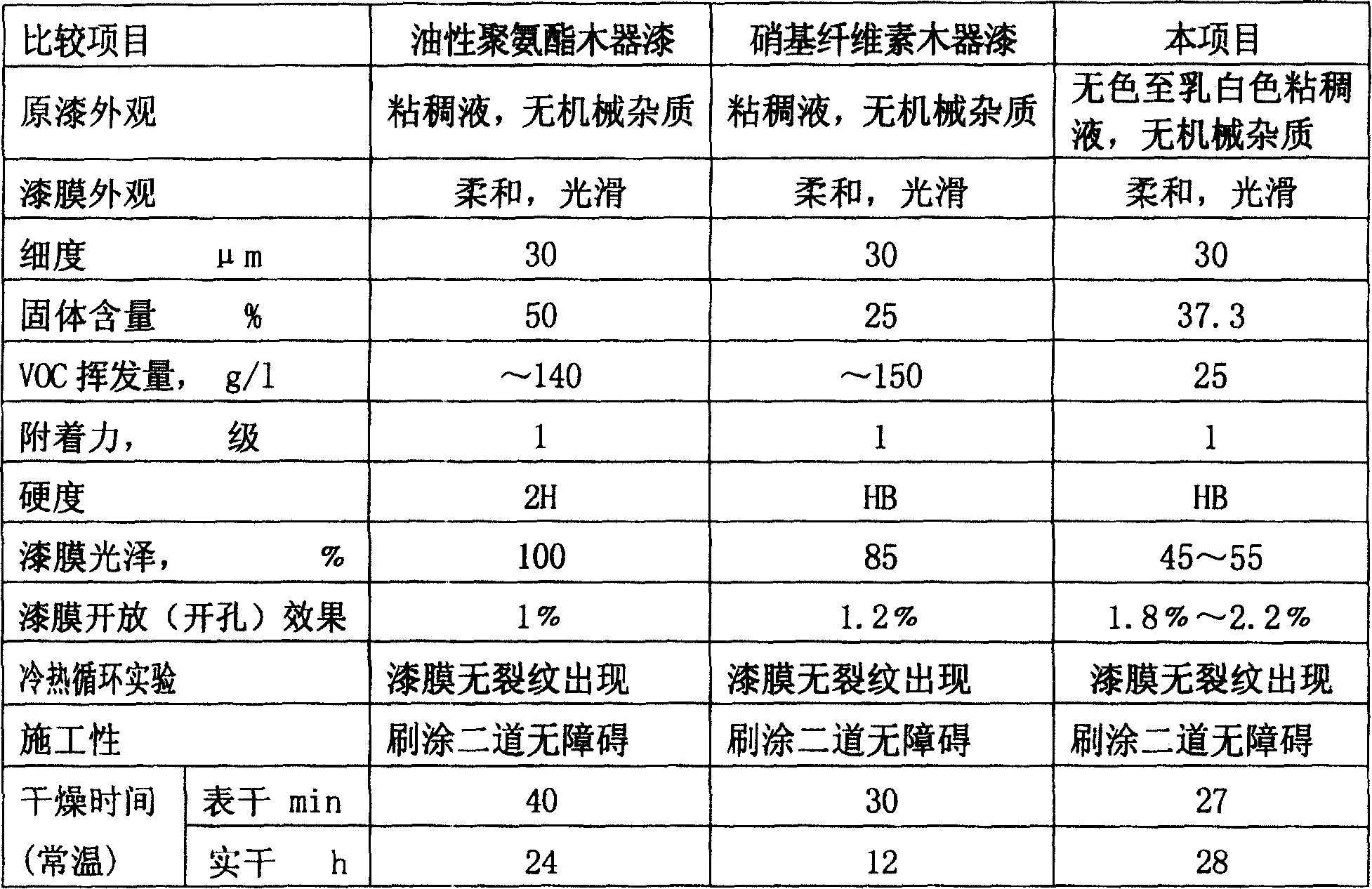

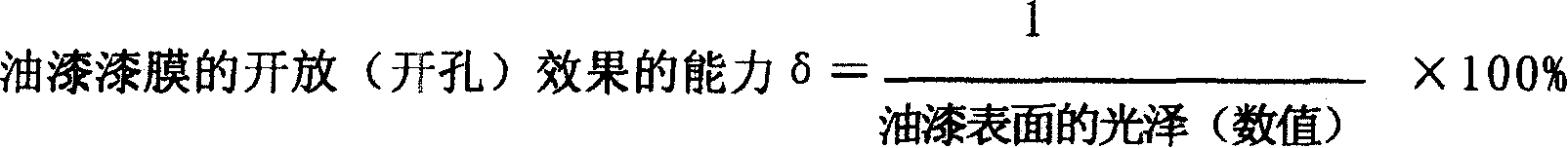

[0044] This specific embodiment 3 draws the result of the following table through comparing with similar products and through testing: the selected experimental plate is the ash three-plywood.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com