Backlight module with diffraction optical element

A technology of diffractive optical elements and backlight modules, applied in optical elements, optics, nonlinear optics, etc., can solve the problems of thick lens thickness, insufficient light transmittance of light-transmitting plate, limited range accuracy of lens surface, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

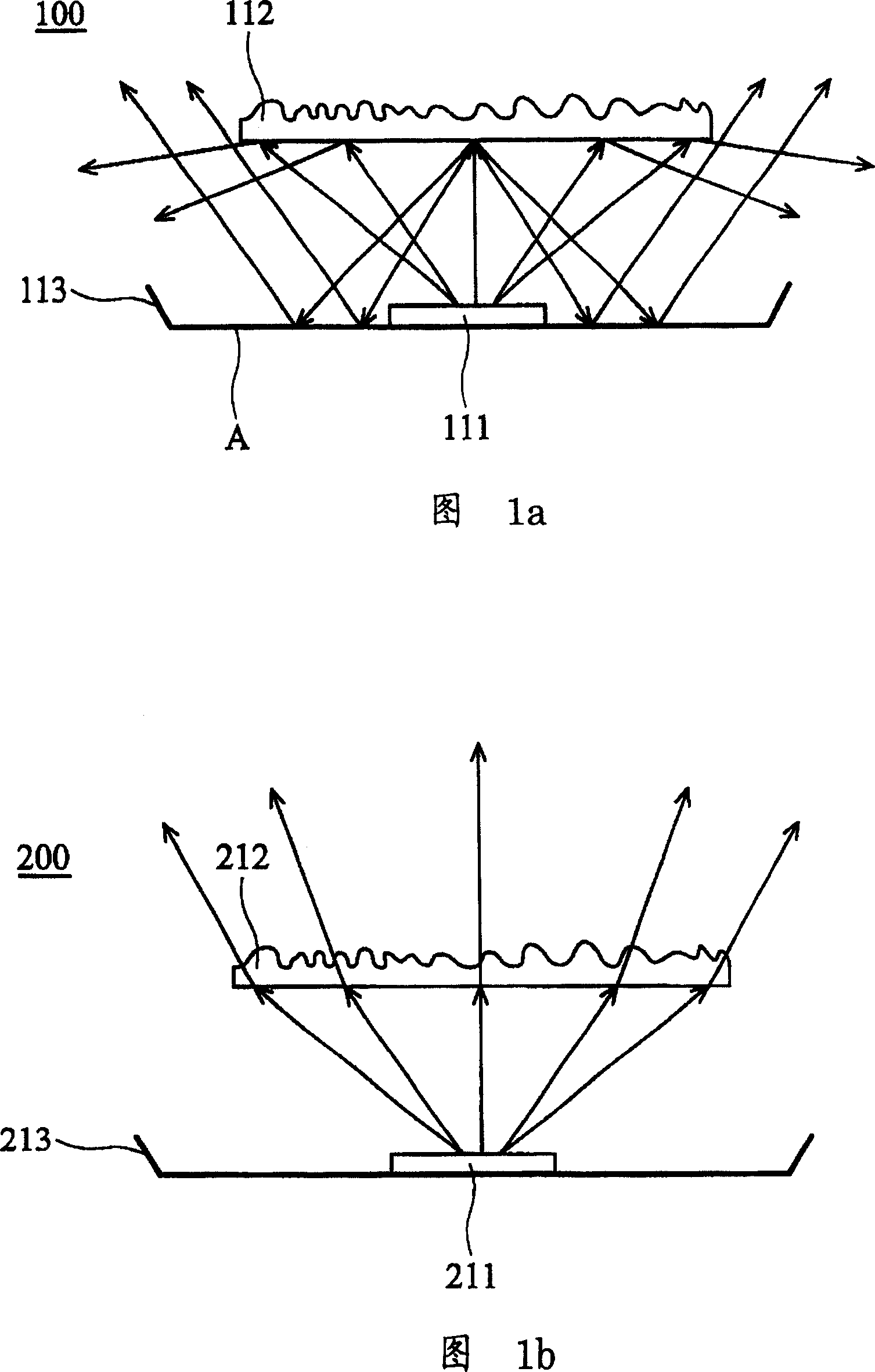

[0017] See Figure 1a first. FIG. 1a shows a schematic diagram of a first embodiment of a backlight module of the present invention. In this embodiment, the backlight module of the present invention is a direct type backlight module 100 , including: a liquid crystal panel (not shown in the figure), a light source 111 , a reflector 113 , and a diffractive optical element 112 . Since the remaining elements are not essential features of the invention, they are not all listed. Wherein, the diffractive optical element 112 is arranged above the light source 111. Through proper phase configuration, the diffractive optical element 112 can modulate the wavefront of the light wave emitted by the light source 111, and then control the direction and distribution of li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com