zoom lens

A zoom lens and lens technology, applied in the field of zoom lenses, can solve problems such as inability to effectively meet market demands, imperfect zoom lens design, and poor brightness perception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

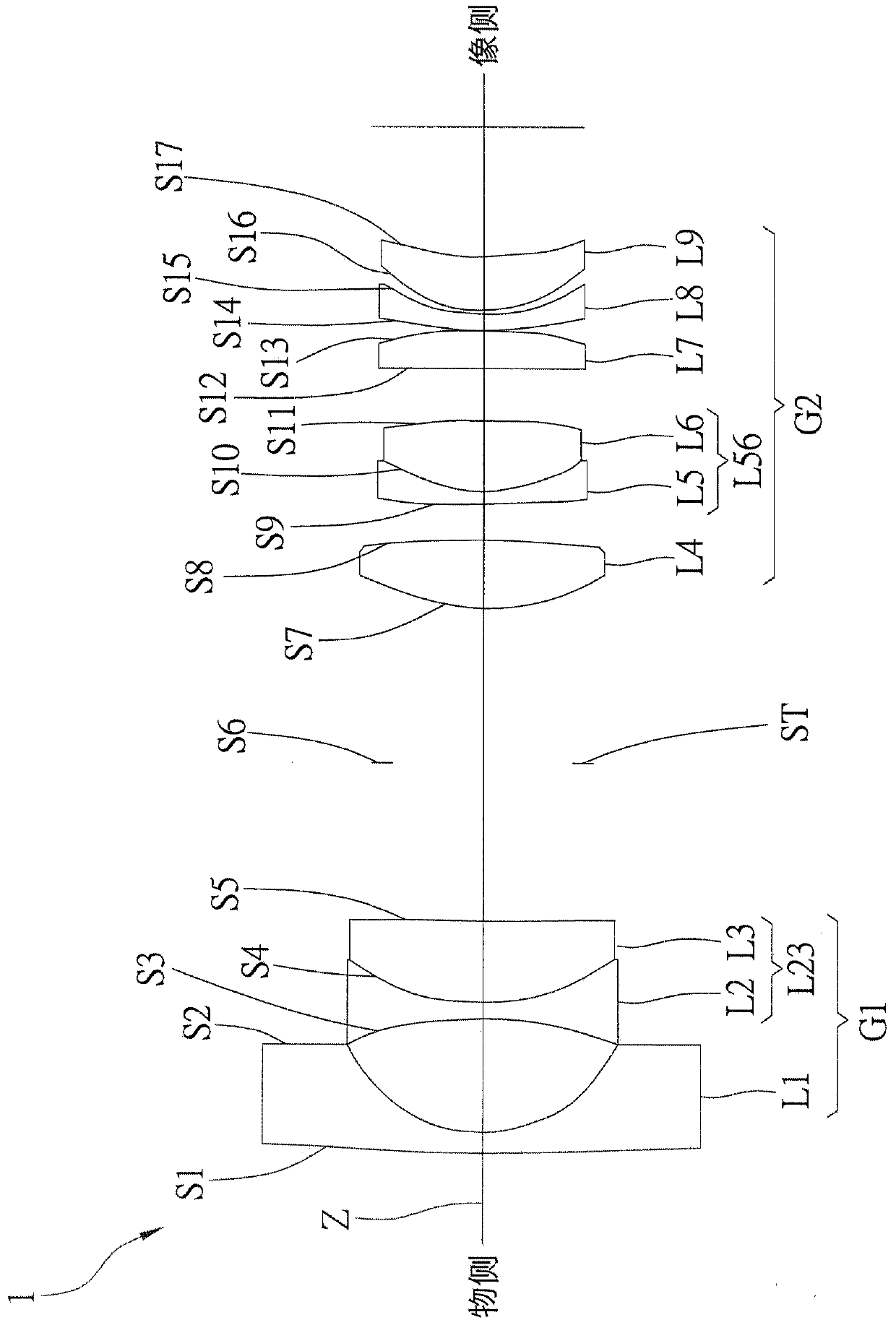

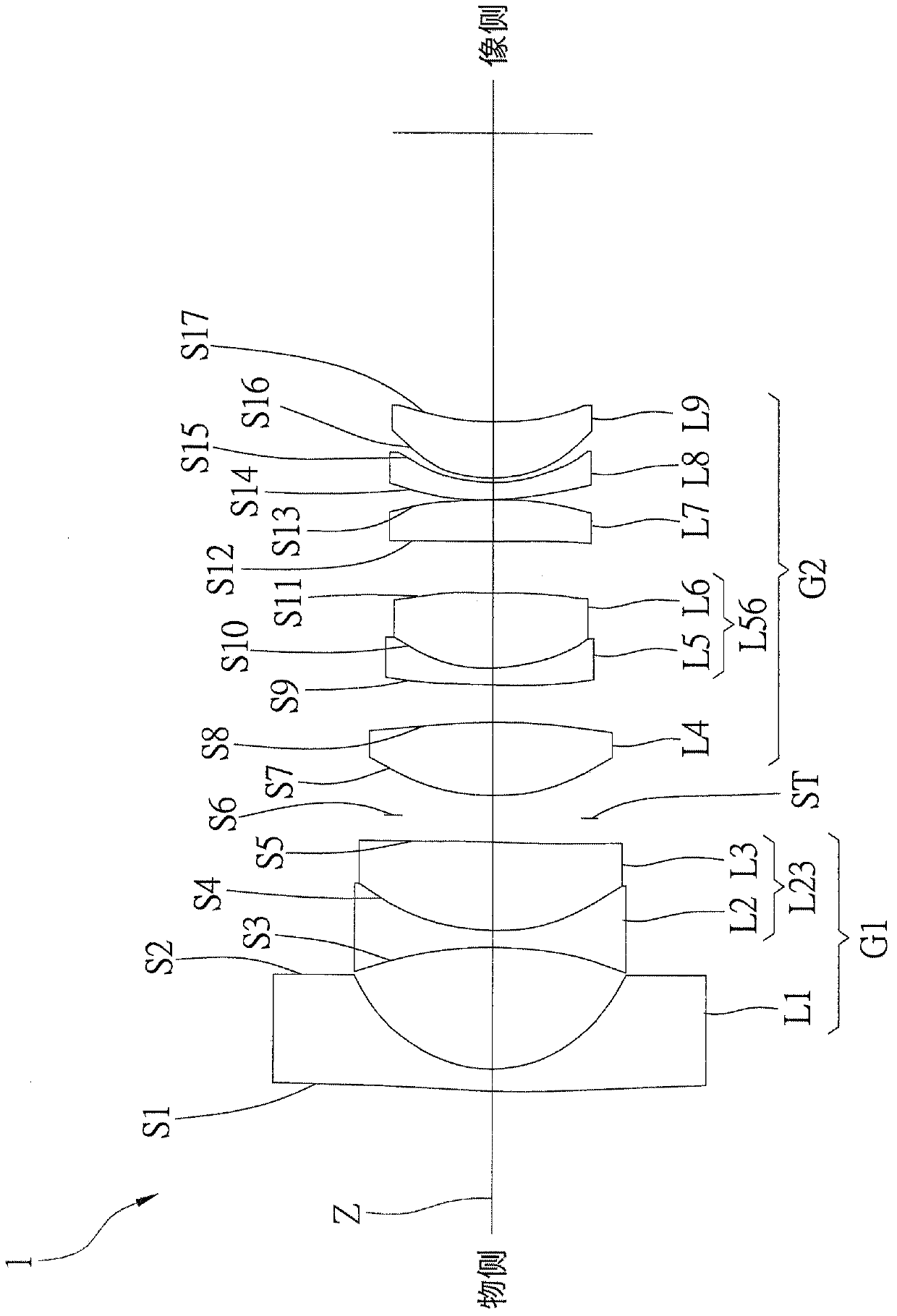

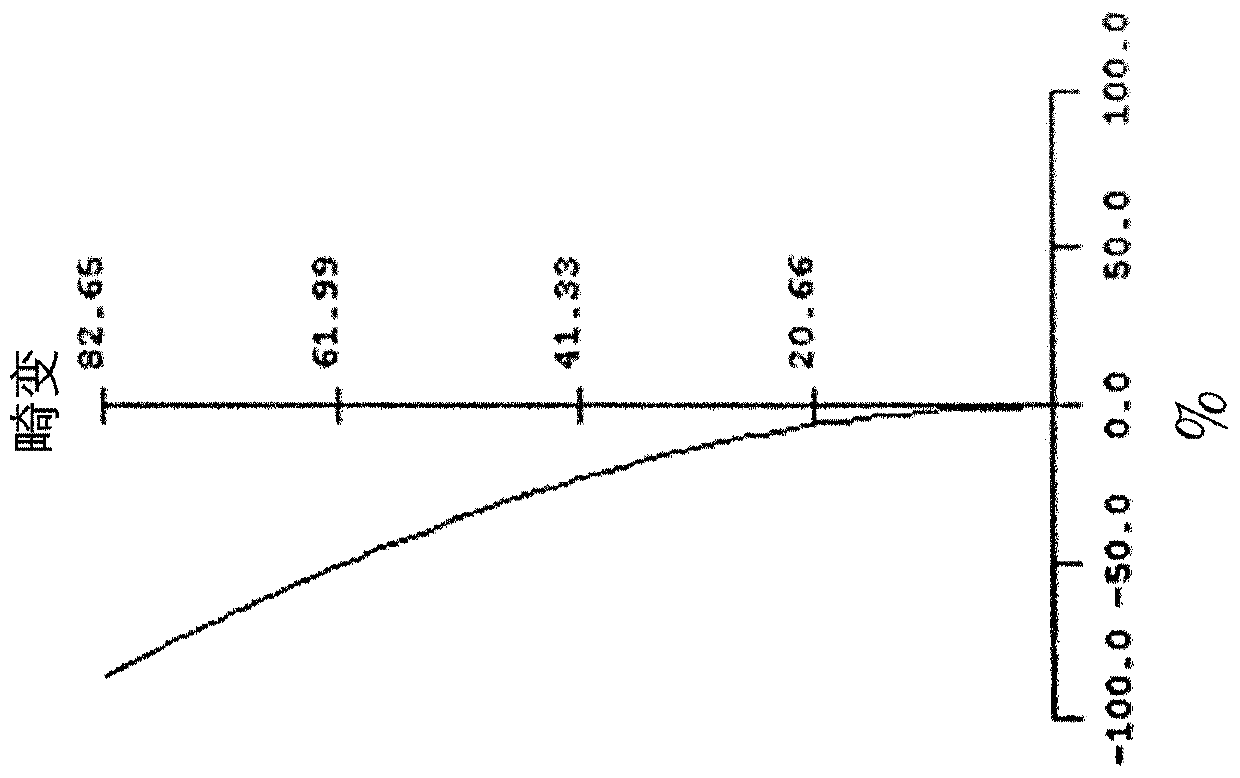

[0061] In order to illustrate the present invention more clearly, the following examples are cited and described in detail in conjunction with the drawings, and please refer to Figure 1A and Figure 1B , Figure 3A and Figure 3B , Figure 5A and Figure 5B , Figure 7A and Figure 7B , Figure 9A and Figure 9BShown are the lens structures of the zoom lenses 1 to 5 of the first to fifth embodiments of the present invention at the wide-angle end and the telephoto lens respectively, wherein:

[0062] The zoom lenses 1 - 5 respectively include a first lens group G1 , a diaphragm ST and a second lens group G2 sequentially arranged along an optical axis Z from an object side to an image side. In addition, according to the needs of use, an optical filter (Optical Filter) can also be provided in the middle of the zoom lenses 1-5 (such as the aperture position, between the second lens group G2 and the image side, etc.) to filter The purpose of improving optical performance c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com