Mixed silk quilt wadding and its producing method

A production method and technology of silk quilts, which are applied in the fields of fabric surface trimming, textiles and papermaking, non-woven fabrics, etc., can solve the problems of incompatibility and achieve high resilience, high strength, and good wet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

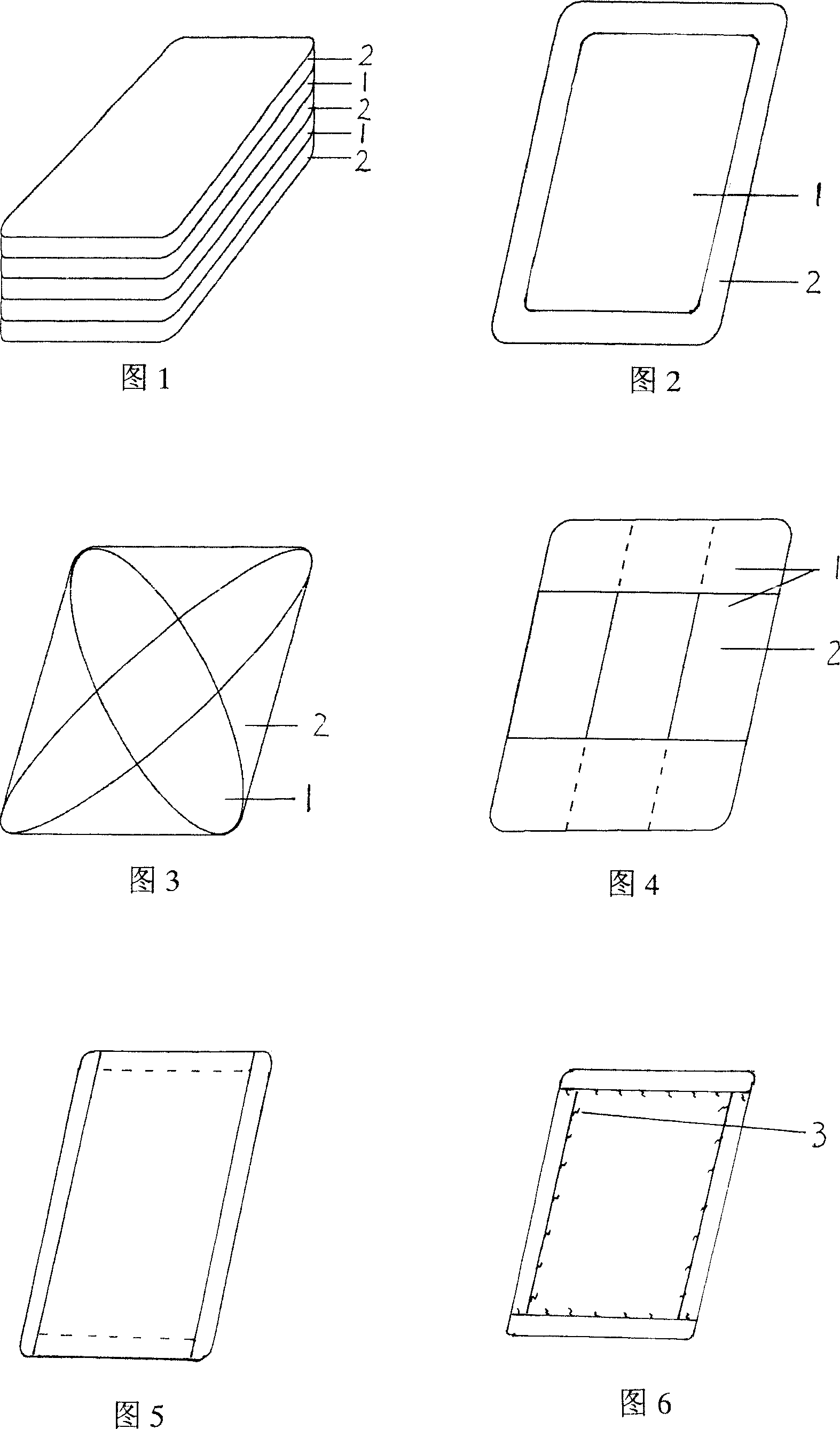

Embodiment 1

[0023] Embodiment 1 is a "mouth" structure, as shown in Figure 1. This example silk quilt weighs 750g. Wherein the tussah silk sheet weight is 75% (there are 7 sheets), and the mulberry silk sheet weight is 25% (there are 12 sheets). Cut tussah silk raw material long cotton pieces (about 50cm×7) into short pieces of 150cm, and pull the four sides of each piece of cotton outward evenly to a rectangular thin piece with a length of 250cm and a width of 190cm. Ribs and black spots on the cotton sheet. The four sides of mulberry silk floss are evenly stretched into a rectangular sheet with the same length and width as the tussah silk sheet 1. Then the two kinds of flakes are laminated according to tussah - mulberry - tussah - mulberry - tussah, and the outermost layer is covered with three layers of mulberry silk flakes to form a superimposed body. After the covering is completed, the four sides of the superimposed body are folded up by 20 cm and superimposed with the floc. Fin...

Embodiment 2

[0024] Embodiment 2 is a "back" structure, as shown in Figure 2. This example silk quilt weighs 1000g. Wherein the weight of the tussah silk sheet is 90% (there are 7 sheets), and the weight of the mulberry silk sheet is 10% (there are 10 sheets). Cut the long piece of tussah silk raw material into short pieces of 100cm, and pull out the four sides of each piece evenly until it is 190cm long and 160cm wide. . The four sides of the mulberry silk floss are evenly stretched into a 270cm long silk floss sheet with a width of 240cm. Then lay the cotton sheets alternately according to tussah-mulberry-tussah-mulberry, place the tussah silk sheets in the middle to form a "hui" shape, and cover the outermost two layers of mulberry silk cotton sheets to form a laminated body. After the covering is completed, the four sides of the superimposed body are folded up by 20 cm and superimposed with the floc. Finally, there are several twisting points between the folded edge and the outer l...

Embodiment 3

[0025] Embodiment 3 is "X" type structure, see Fig. 3. The heavy 1500g of silk quilt of this example adopts the tussah silk sheet of 45% weight (having about 8 pieces) and the mulberry silk flake of 55% weight (having about 55 pieces). Cut the tussah silk sheet to a length of 150 cm, and pull the four sides of each sheet outward evenly to form an oblong shape. Every two pieces of cotton are crossed and stacked to form an "X". Then stretch the four sides of the mulberry silk sheet evenly, so that the size of each side is 20cm larger than the size of the silk quilt, and lay them alternately with the "X" cotton sliver, with four layers of mulberry silk sheets on the upper and lower surfaces. After covering, fold up 20cm on each side and twist with the outer layer in a few points. In this case, the "X" frame is relatively strong, and the four sides are thin and soft, which is not easy to lose shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com