Method of manufacturing templet and optical information storage medium

A manufacturing method and optical information technology, which are applied in the manufacture of optical record carriers, optical record carriers, etc., can solve the problems of strong adhesion between template and spacer layer, low yield rate of disc manufacturing process, etc., so as to reduce production cost and improve yield rate. , the effect of small stripping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

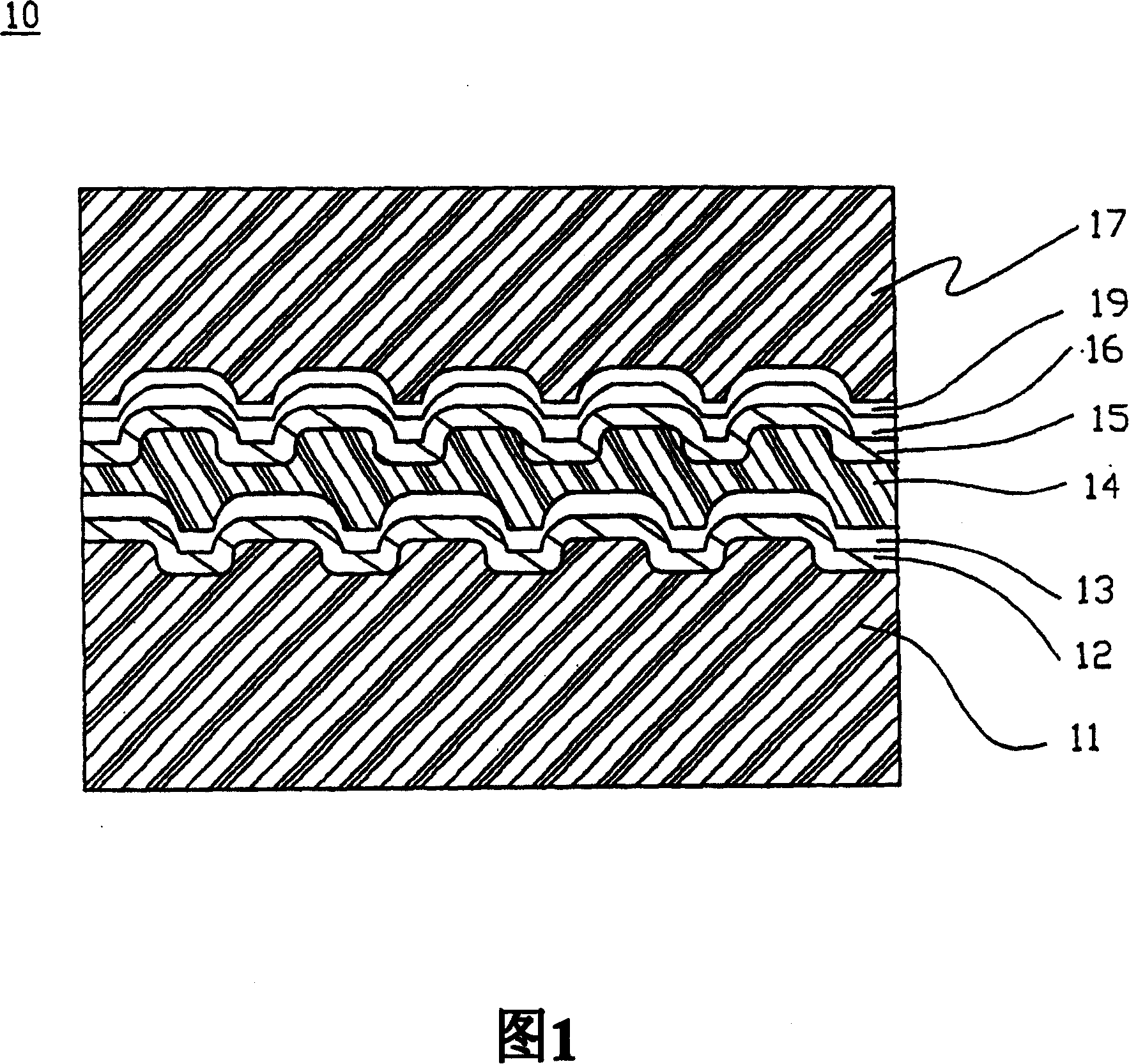

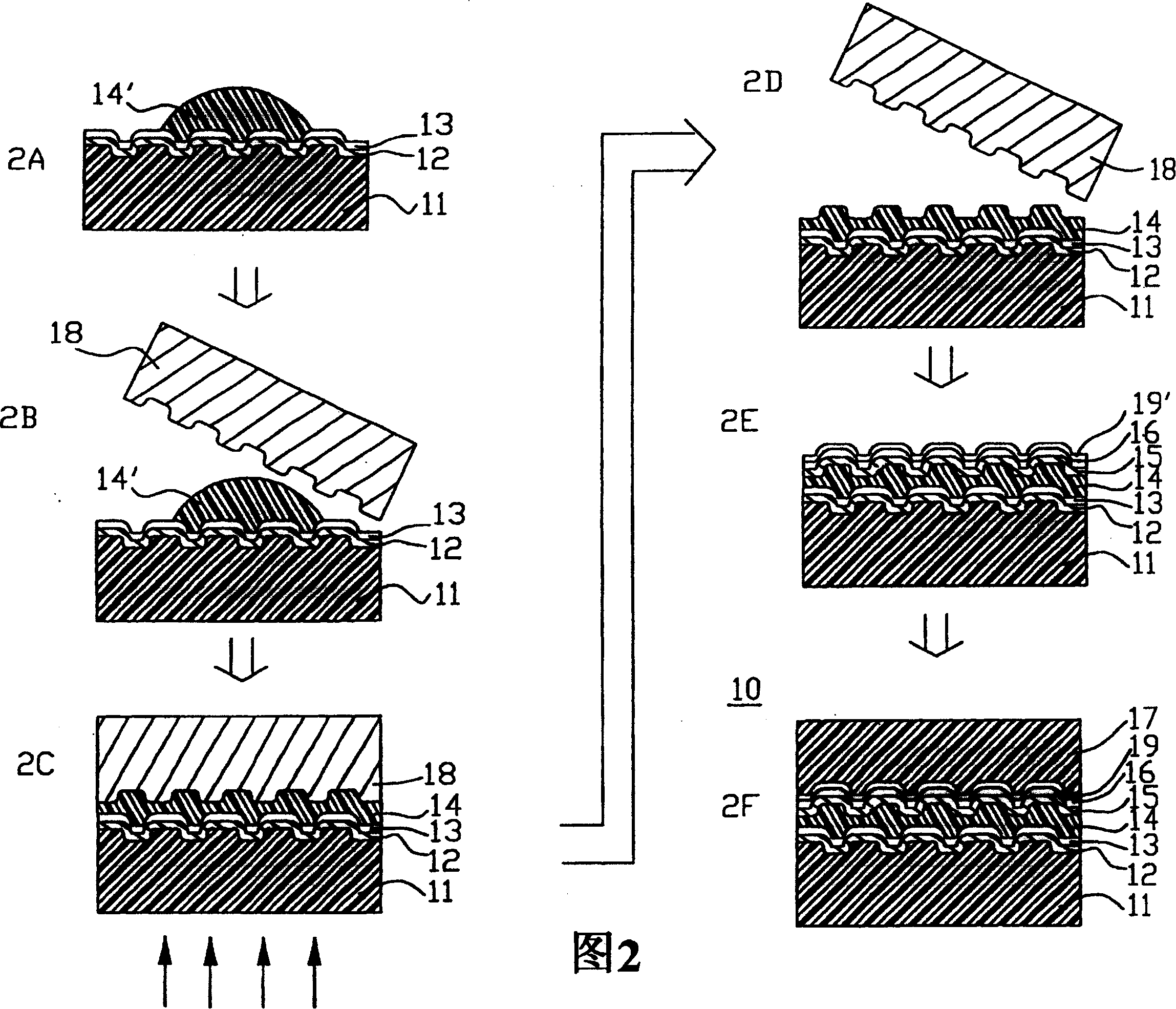

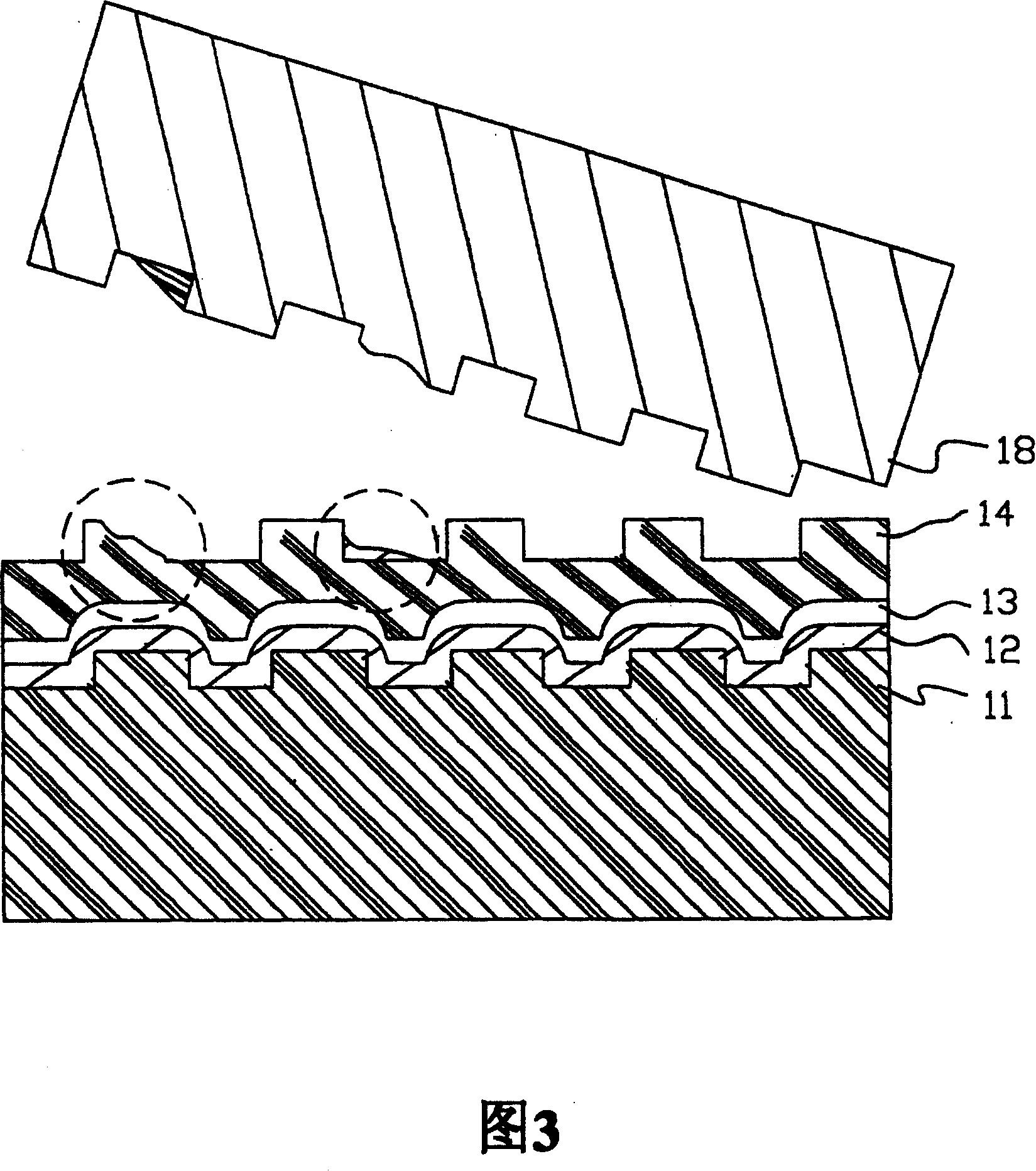

[0059] The template and the manufacturing method of the optical information storage medium according to the preferred embodiment of the present invention will be described below with reference to the relevant drawings.

[0060]First, please refer to FIG. 4 to FIG. 7 to illustrate the manufacturing method of the optical information storage medium according to the preferred embodiment of the present invention.

[0061] In this embodiment, the template is used in a photopolymerization process (Photo-Polymerization Process, 2P Process) to manufacture an optical information storage medium. The optical information storage medium is a writable digital laser disc (DVD-R), and in this embodiment, a single-sided double-layer DVD-R formed by a 2P process is used to illustrate the manufacturing method of the optical information storage medium of the present invention the preferred embodiment.

[0062] As shown in FIG. 4, in this embodiment, the manufacturing method of the optical informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com