Radial coreless permanent magnet motor

A permanent magnet motor, ironless technology, applied in the field of electric motors, can solve the problems that the advantages are not clearly reflected, the sine degree of the air gap flux density is poor, and the power level is low, so as to achieve small vibration and improve the air gap flux density waveform , the effect of high friction torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Further describe content of the present invention below in conjunction with accompanying drawing and embodiment:

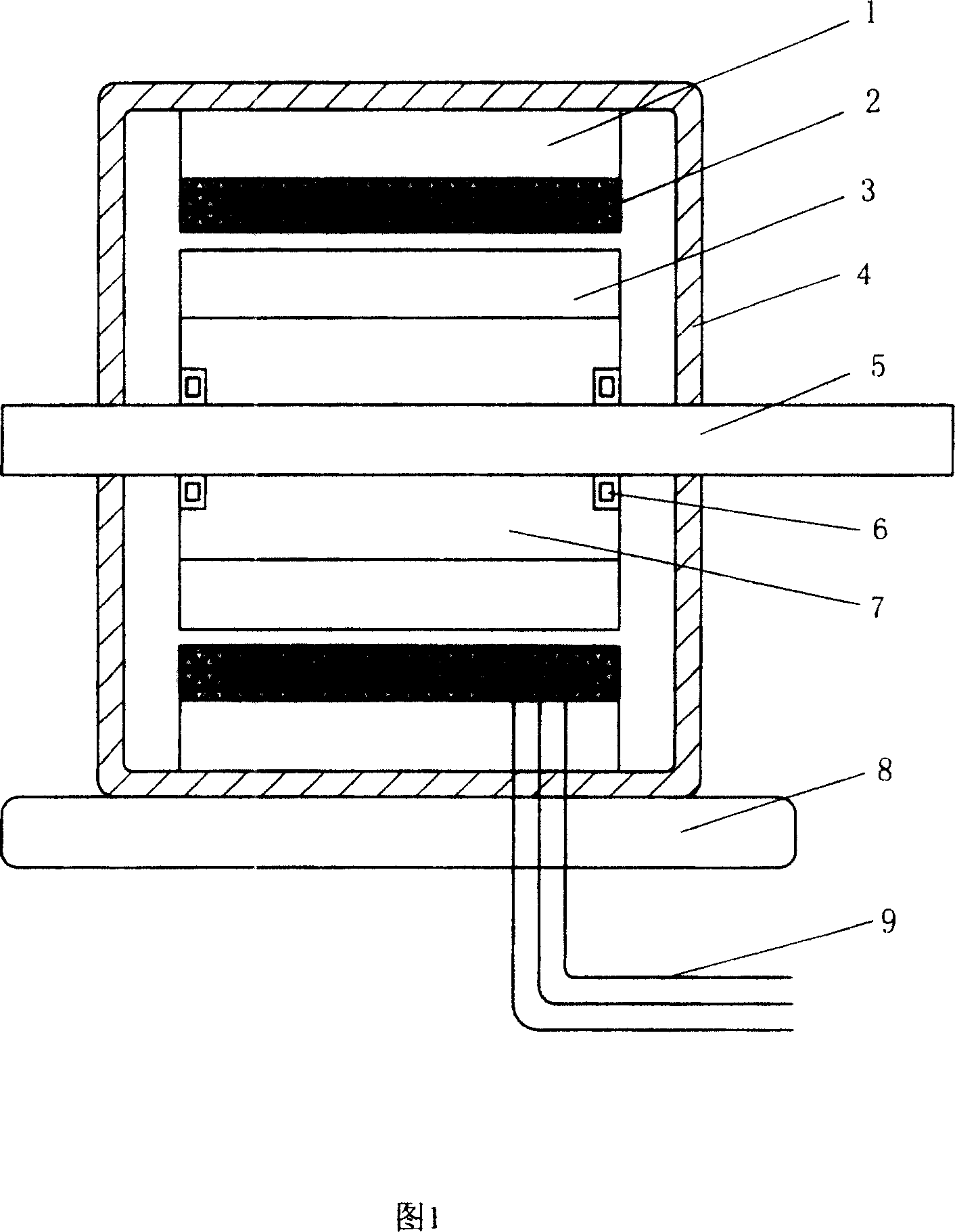

[0011] The mechanical structure of the present invention is shown in Figure 1, comprises housing 4, machine base 8, rotating shaft 5, bearing 6, rotor support 7, stator yoke 1, stator winding 2, housing 4 is placed on machine base 8, and motor shaft 5 passes through The bearings 6 on the inner walls of both sides of the casing 4 are fixed in the middle of the casing 4, and the rotor and the stator are sequentially arranged radially around the rotating shaft 5; the rotor part includes a permanent magnet 3 and a rotor bracket 7, and the rotor bracket 7 is fixed on the motor shaft 5 , used to support the rotor, the permanent magnets 3 are distributed around the rotor bracket 7; the stator part includes the stator yoke 1, the stator winding 2, the stator winding 2 is arranged around the permanent magnet 3, and the cylindrical coil of the stator is fixed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com