High precision hot press silicon nitride ceramic ball bearing and its manufacturing method

A technology of silicon nitride ceramic balls and manufacturing methods, which is applied in the direction of ball bearings, manufacturing tools, bearing components, etc., can solve the problems that high-precision ceramic bearings cannot be purchased, hot-pressed silicon nitride materials are difficult to process hard and brittle materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063]The specific technical solutions of the present invention will be further described below in conjunction with embodiments:

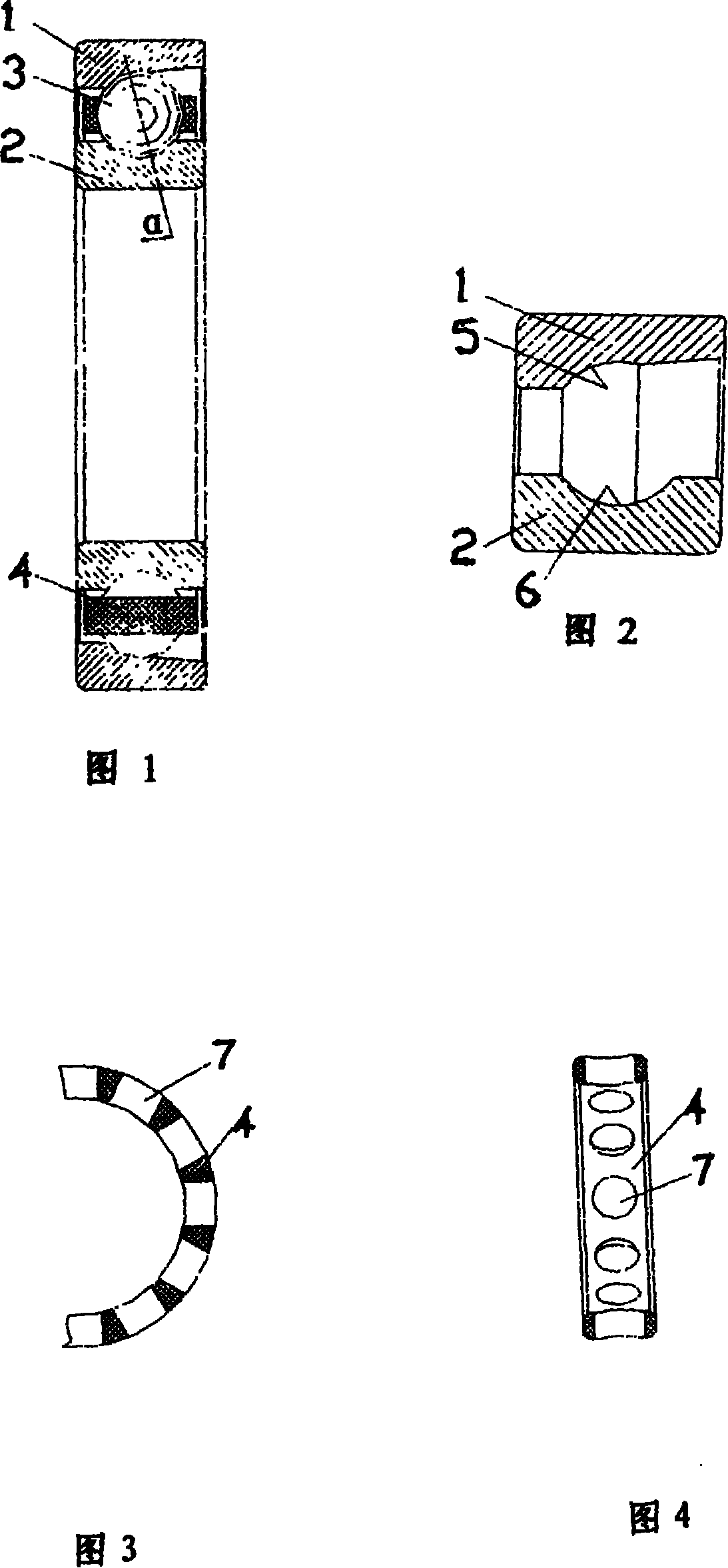

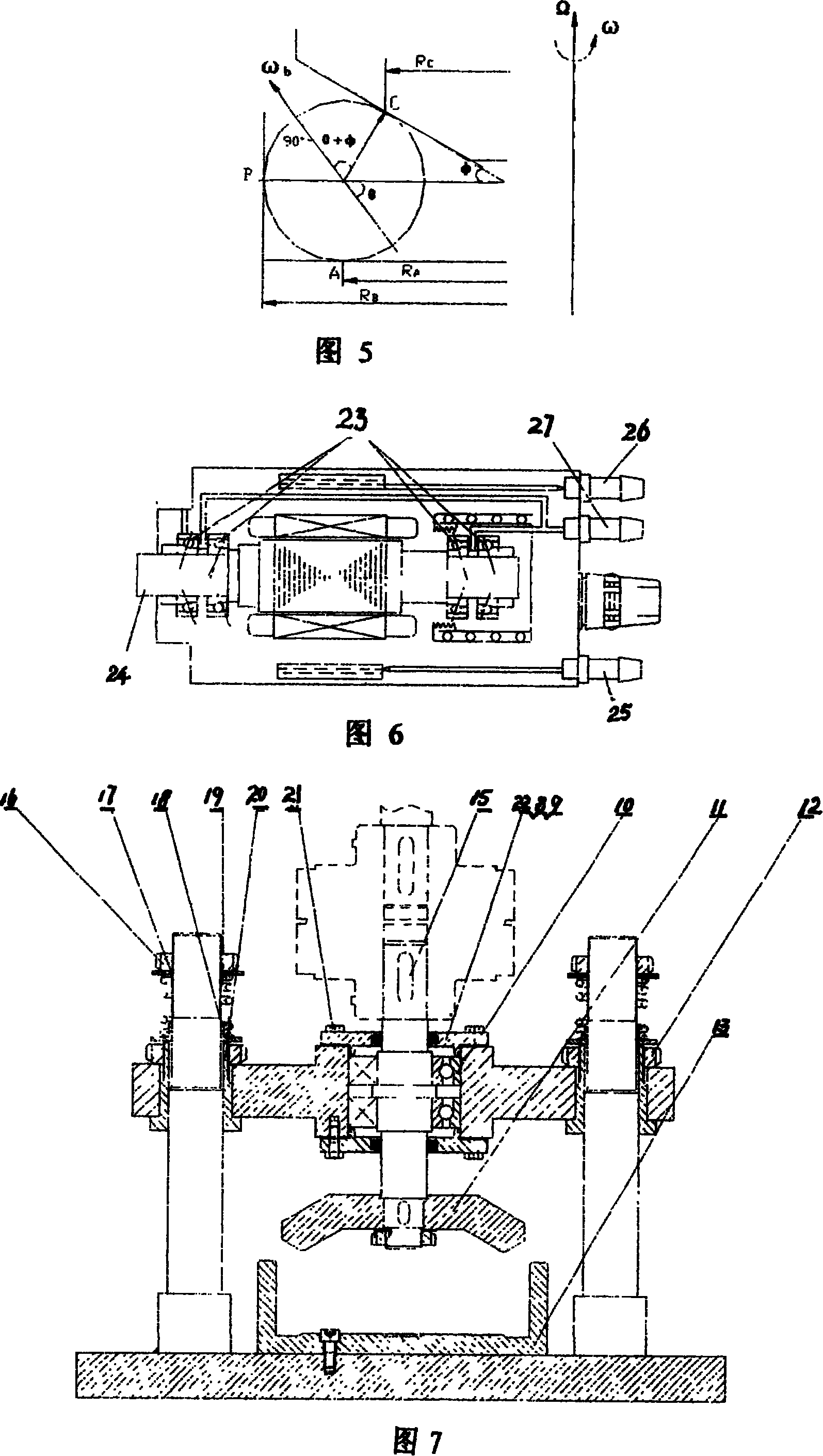

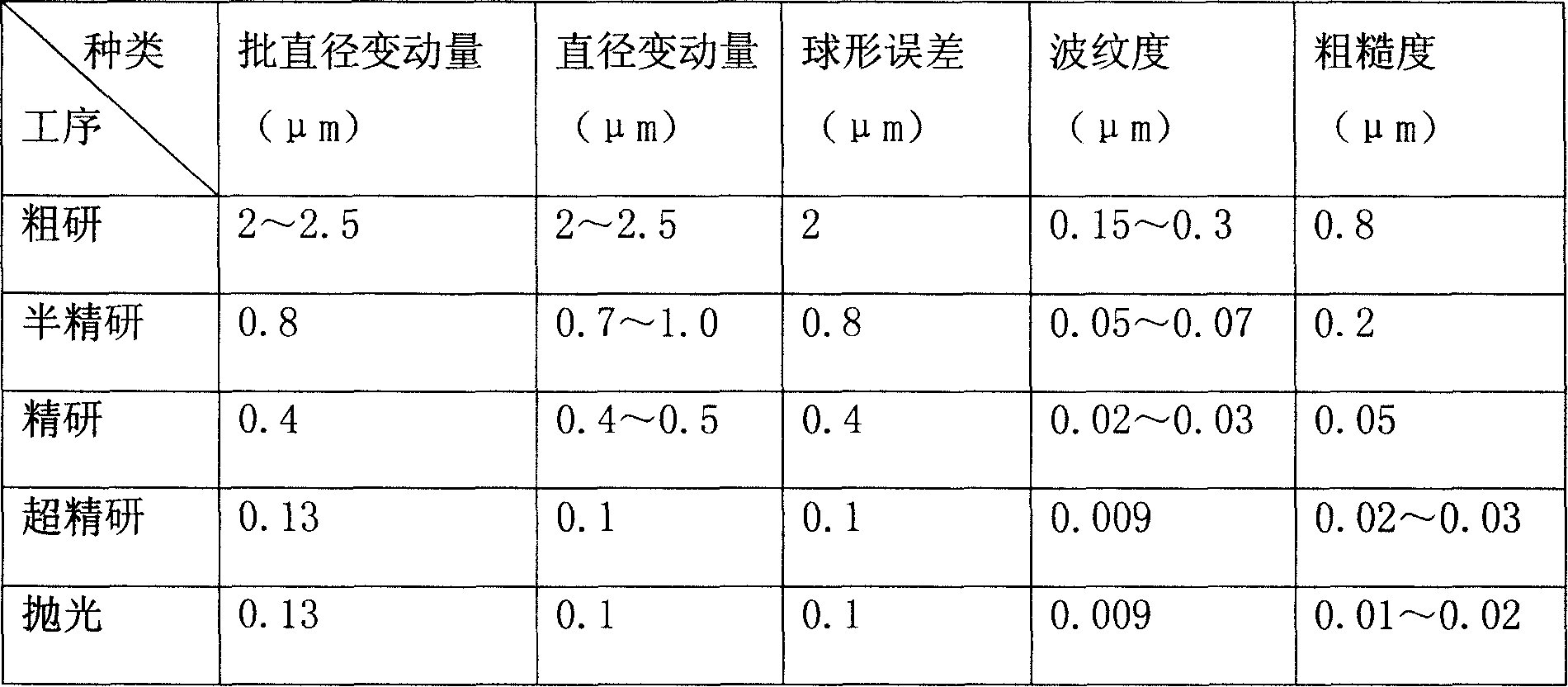

[0064] The high-precision hot-pressed silicon nitride ceramic ball bearing shown in Figures 1 to 4 includes: an inner ring 2 and an outer ring 1 made of steel. The inner ring 2 and the outer ring 1 respectively have two facing each other. One of the arc raceways 5 and 6; a number of ceramic ball rolling elements 3 arranged between and in contact with the raceways 5 and 6 of the inner and outer rings; one set between the inner and outer rings 1, 2 In order to maintain the ceramic ball rolling element 3 rolling element isolation ring, that is, the cage 4. The ball bearing is of angular contact type, that is to say, the outer ring 1 and the inner ring 2 respectively have a respective outer raceway 5 and an inner raceway 6, which face each other with their concave surfaces facing each other. In this example , The outer ring 1 has a lock, which makes the be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com