Anti-explosion image pickup instrument

A camera and rotating cylinder technology, which is applied in the field of explosion-proof cameras, can solve the problems of difficult installation and maintenance, poor environmental adaptability, poor operation accuracy, etc., and achieve the effects of easy installation and maintenance, good operation accuracy and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

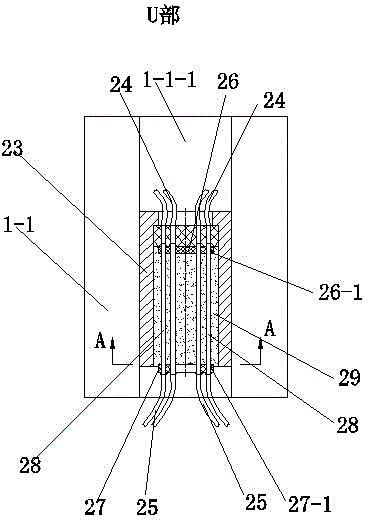

[0032] see Figure 1~9 As shown, an explosion-proof camera includes a base 1, a rotating cylinder 2, a camera 100 and a camera rotating device 200, the camera 100 and the rotating cylinder 2 are connected through the camera rotating device 200,

[0033] see figure 2As shown, a cylinder rotating device 300 is also included, and the cylinder rotating device 300 includes a transmission substrate 3, a motor mounting bracket 4, a motor 5, a driving gear 6, a driven gear 7, a spring 8, a spring pressure ring 9, a transmission shaft 10, The first bearing 11-1, the second bearing 11-2 and the bearing pressure ring 12, the base 1 has a shaft seat 1-1, the shaft seat 1-1 has a shaft hole 1-1-1, and the transmission shaft 10 is fixedly connected In the shaft hole 1-1-1, the middle part of the transmission base plate 3 is provided with a mounting ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com