Fatty acid ester alkoxylating method and dedicated equipment therefor

A technology for fatty acid ester alkoxylation and alkoxylation, which is applied in the field of fatty acid ester alkoxylation method and its special equipment, and can solve unsuitable fatty acid ester alkoxylation and unsuitable alkoxylation methods, etc. problems, achieve the effects of suppressing side reactions, excellent reactivity and selectivity, and short production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This example is the preparation of the catalyst.

[0029] Weigh 18KgAl(NO 3 ) 3 .9H 2 O, add 22.5Kg of deionized water to prepare aluminum nitrate solution, and pour it into the high-level liquid tank when it is completely dissolved. Add 175Kg of deionized water to a 500L enamel kettle, start stirring, slowly add 23KgMgO in batches from the manhole at 25°C to make it completely dispersed, after adding MgO, stir at constant temperature for 20 minutes, and then slowly add dropwise at 25°C. A good aluminum nitrate solution, drip for 20 minutes, mature at a constant temperature of 25°C for 50 minutes, and then wash. Add 200Kg of deionized water and stir for 10 minutes, filter under reduced pressure, and repeat washing and filtering until the pH of the system is between 6.5-7.5. Add 8Kg of clay to the filter cake, mix it evenly, and then press it into a shape. The shaped ring-shaped catalyst is placed in a thermostat and dried at 100°C for 10 hours. Then take 5Kg of 5% potassium...

Embodiment 2

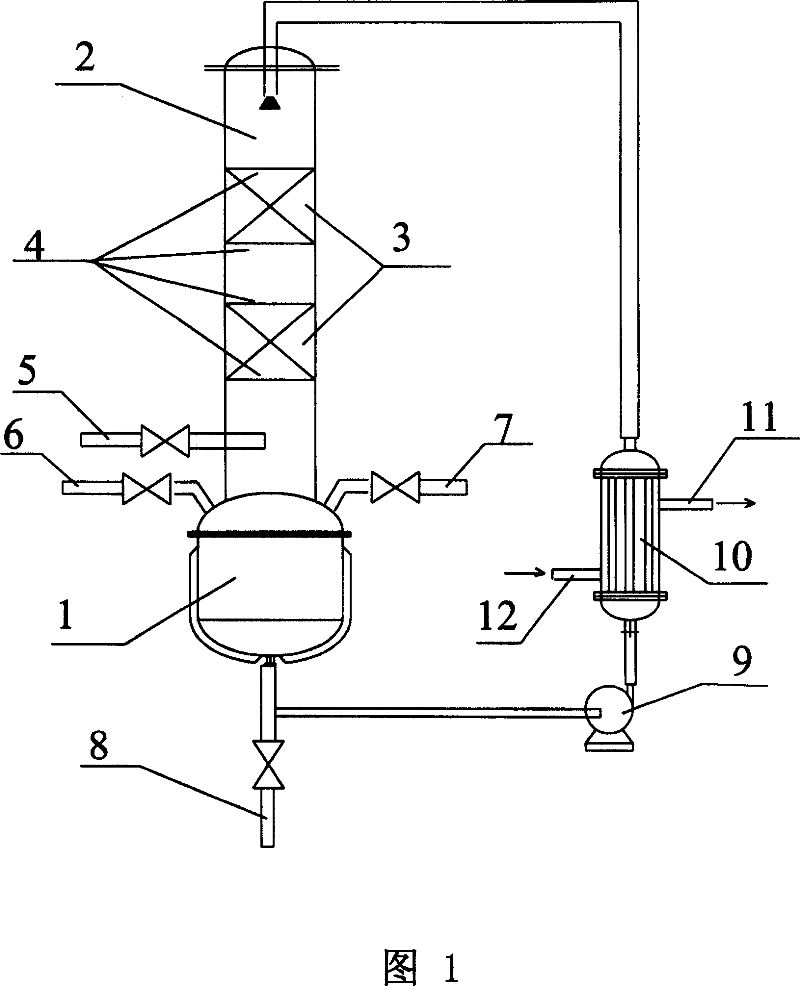

[0031] We took 20Kg of the ring-shaped catalyst of Example 1 and installed it on the two-layer catalyst bed of the equipment of the present invention, and made the catalyst of each bed 10Kg, and fixed it with a sieve plate with an aperture of 3mm.

[0032] All the following examples are performed on this equipment. For different kinds of products, we use 100℃ water circulation washing reaction equipment for 20 minutes, 50℃ ethanol circulation washing for 20 minutes, and then vacuum drying at 100~110℃ for 20 minutes. Continue to use after handling the reaction equipment.

[0033] Vacuum 15Kg of methyl laurate into the tower kettle, start the circulation pump and the vacuum pump, raise the temperature to 100-110°C for vacuum dehydration for 20-40 minutes, and then stop the dehydration. Raise the temperature to 140℃, open the ethylene oxide feed valve, and introduce 0.5Kg of ethylene oxide. At this time, the pressure is 0.2mPa. Close the feed valve. When the temperature of the system...

Embodiment 3

[0035] Vacuum 5Kg methyl laurate into the tower kettle, start the circulation pump and vacuum pump, raise the temperature by 100-110°C, vacuum dehydration for 20-40 minutes, and then stop dehydration. Increase the temperature to 140°C, open the ethylene oxide feed valve, and pass in 0.5Kg of ethylene oxide. At this time, the pressure is 0.15mPa. Close the feed valve. When the system temperature rises and the pressure drops, continue to pass in ethylene oxide Alkane, keep the reaction temperature at 135-155°C and the pressure at 0.4mPa. After 18 minutes, 44.5Kg of ethylene oxide was introduced, the epoxy feed valve was closed, the feeding was stopped, the material was kept circulating for 20 minutes, the temperature was lowered to 60-80°C, the circulation pump was turned off, and the finished product was 49.7Kg. The results of the reaction are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com