Construction cavities forming method and object containing cavities fabricated thereby

A technology of structures and holes, applied in construction, manufacturing tools, ceramic molding machines, etc., to achieve the effects of reducing construction costs, easy storage, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

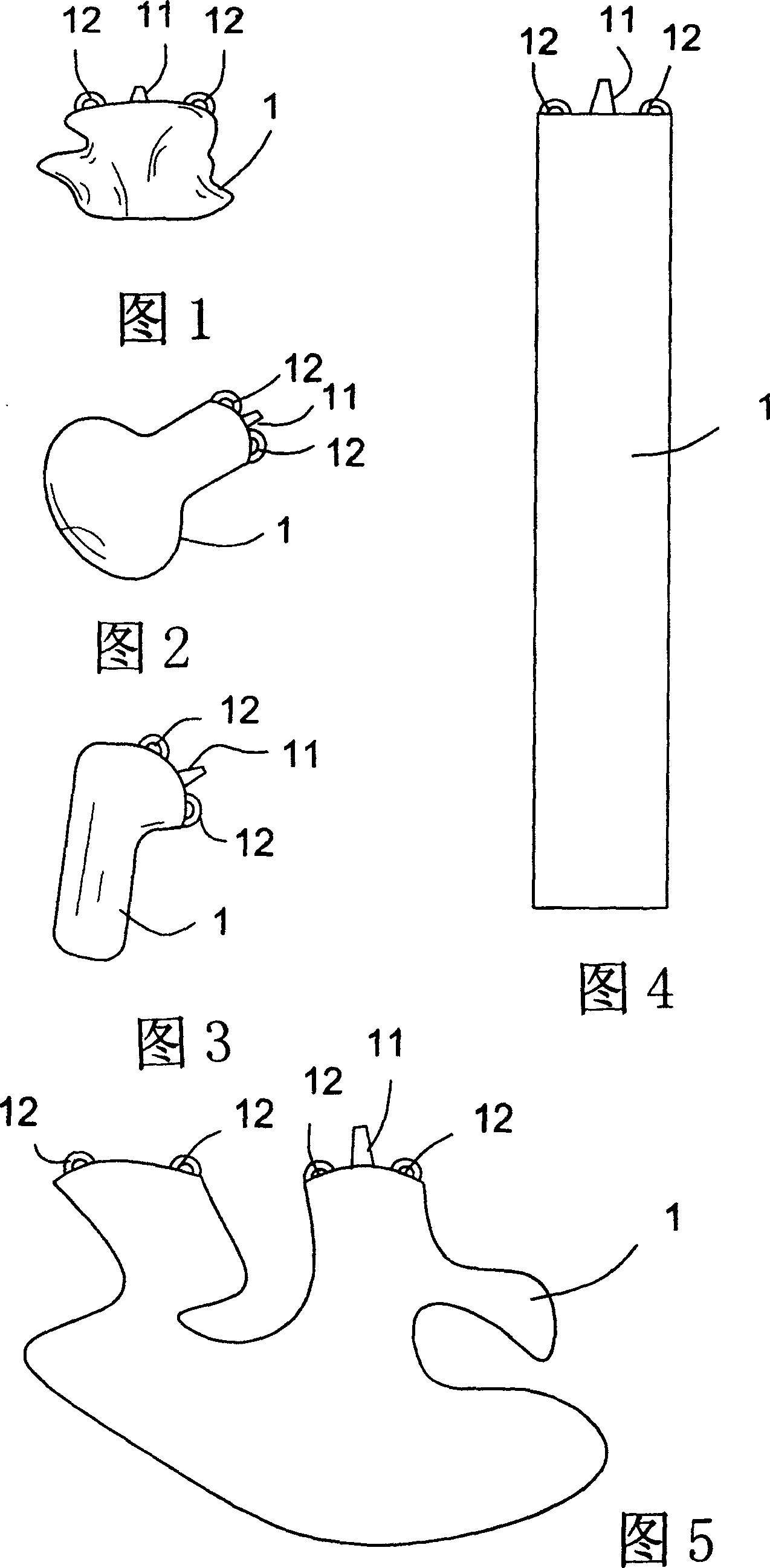

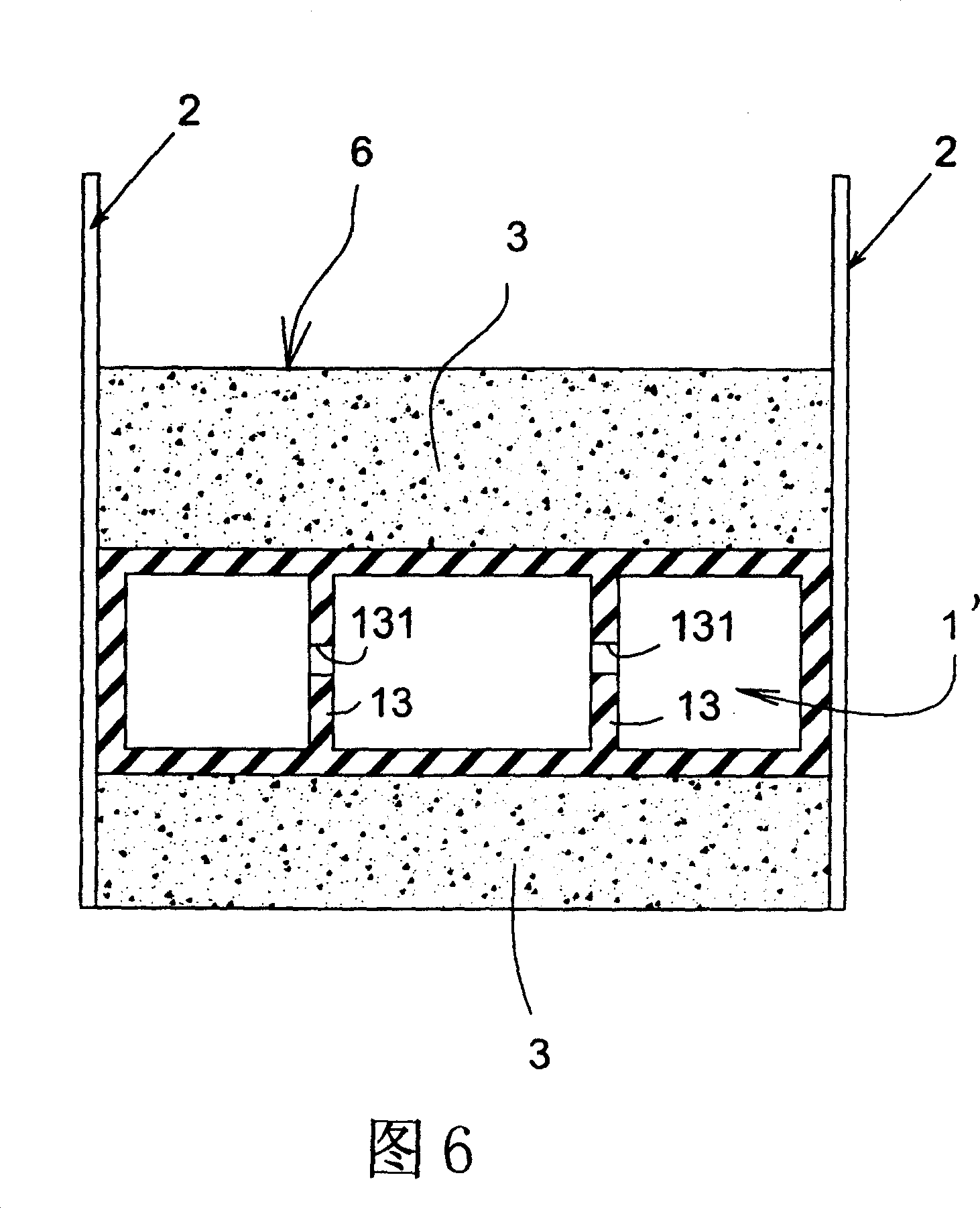

[0042] Please refer to Fig. 1 to Fig. 5, the present invention relates to a method for forming a hole in a structure and an object containing a hole made therefrom. And the improvement of the pouch 1 used in the method for forming holes in the structure of the object containing holes made by this method.

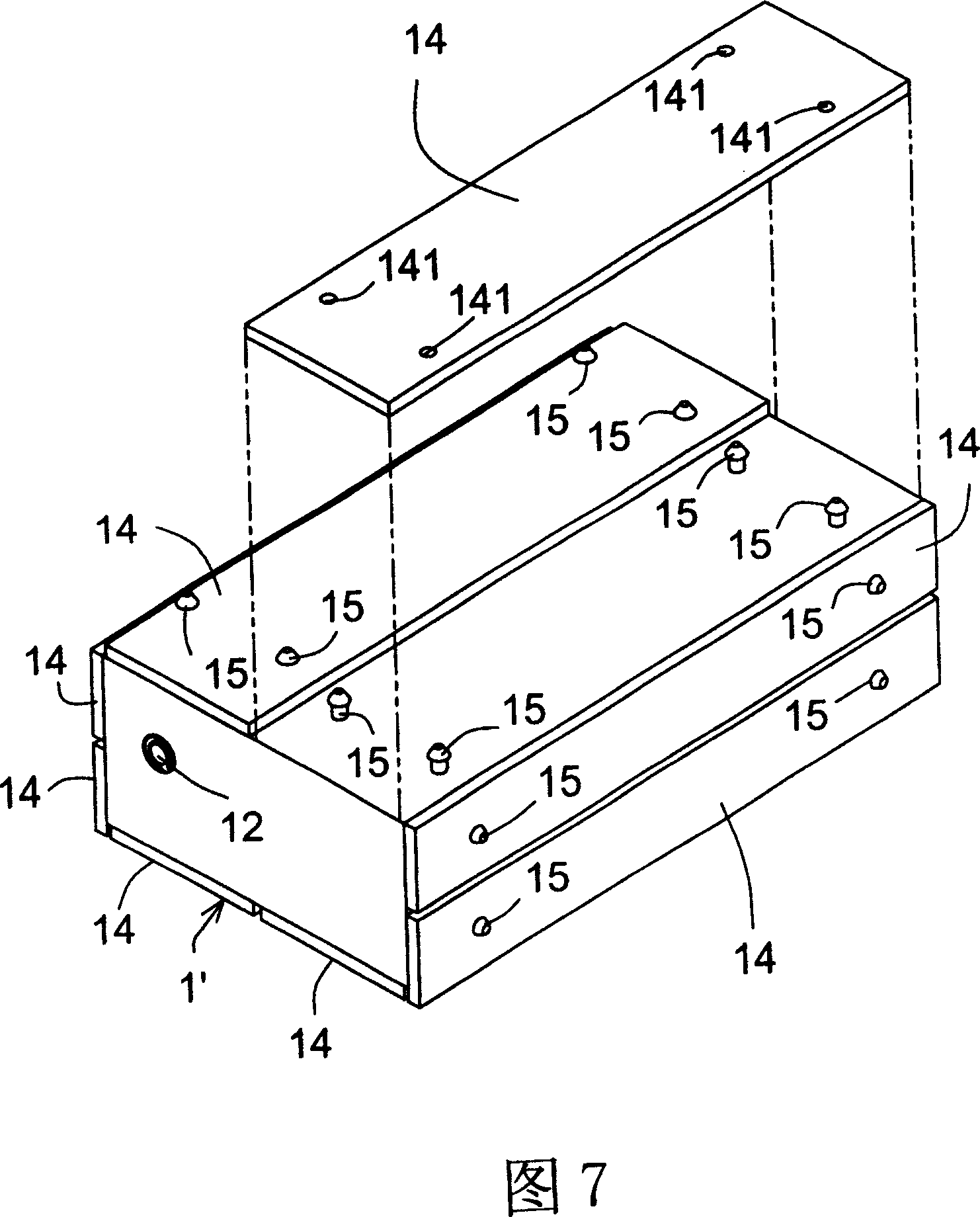

[0043] The method for forming holes in structures disclosed by the present invention can also be used to build covers 51 of structures such as ditches 5 as shown in Fig. 7, Fig. 8 and Fig. 9. After the side wall 52 of the side wall 52 on both sides, a vertically long pouch 1' is horizontally placed on the top between the side walls 52 on both sides, so that after the elongated pouch 1' is filled with gas from its inflation nozzle 11, its two sides are tightly closed. Supported on the side walls 52 on both sides of the ditch 5 , the elongated pouch 1 ′ is formed on the formwork of the cover 51 of the ditch 5 formed by grouting. After the cover body 51 formed by grouting is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com