Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Prevent longitudinal deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

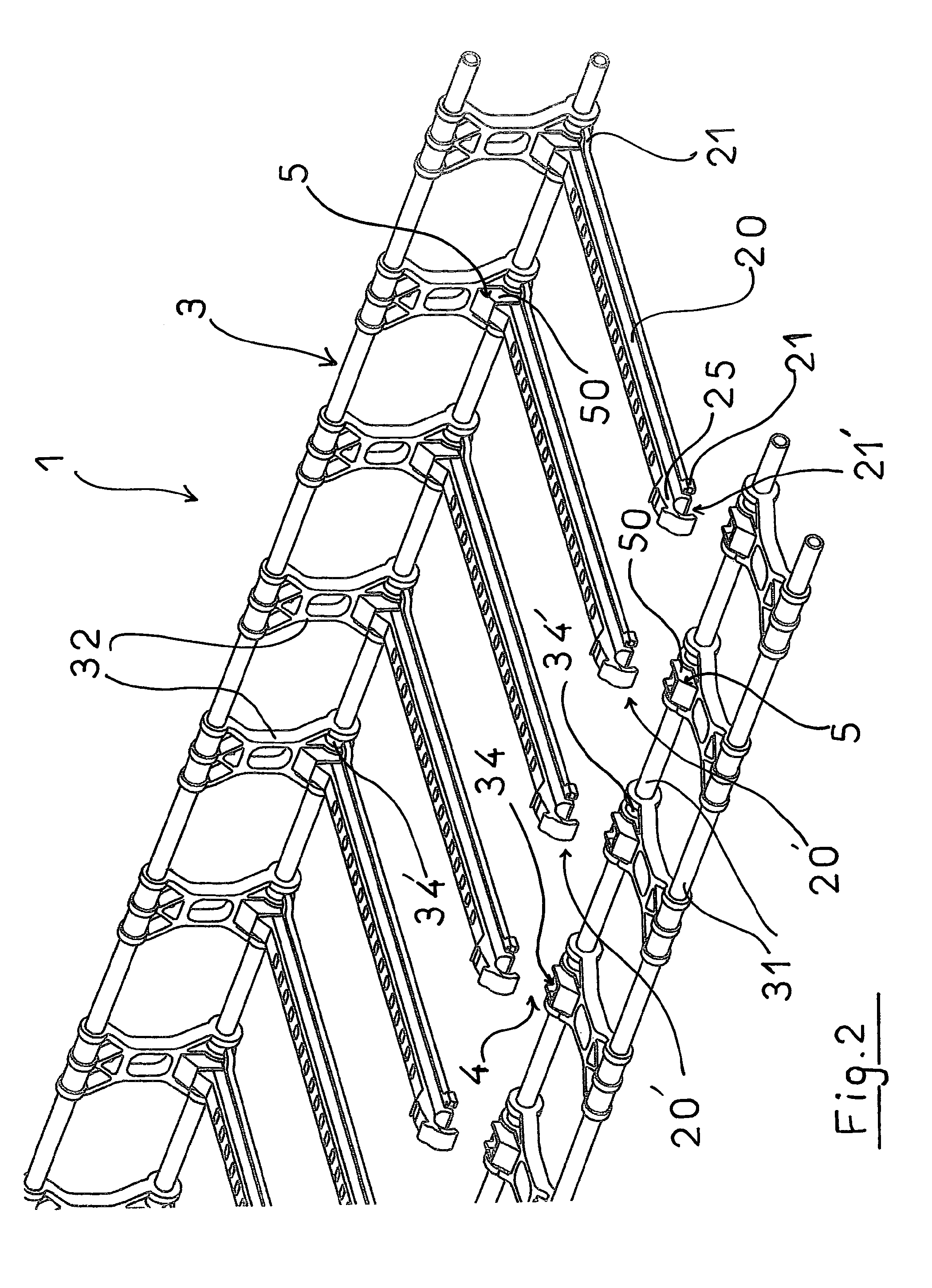

Cable routing device

InactiveUS20100181438A1Weight optimizationIncrease installation costPipe supportsElectrical apparatusPlastic materialsCoupling

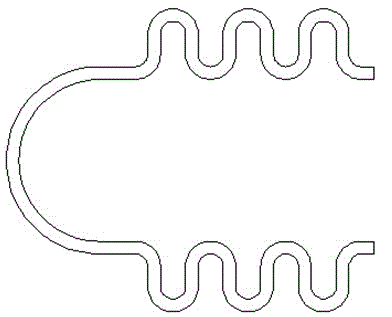

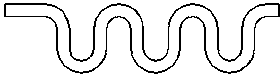

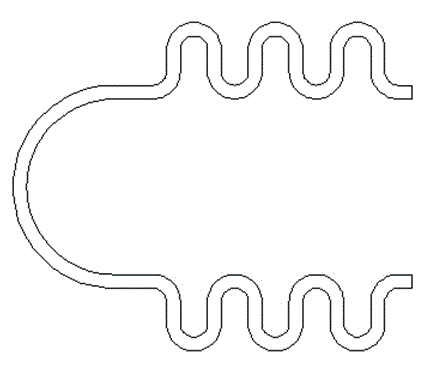

Device for routing cables, more particularly intended for routing and distributing electric cables having an elongated shape (1) with a U-shaped cross-section consisting of an assembly of two side posts (3) forming the arms of the U and of a base (2) forming the bottom of the U. The side posts (3) and the base (2) are substantially made from a composite material and / or a strengthened plastic material and in that at least one side post (3) is pivotally mounted while being jointed to the base (2) about an axis of rotation (30) by at least one hinge (4) and in that it comprises snap-coupling means (35,26,63,7) and abutment means (22,23,38,29,27) capable of locking the side post perpendicularly to said base (2) under the action of its rotation.

Owner:CHAUZU FRANK +1

Cable routing device

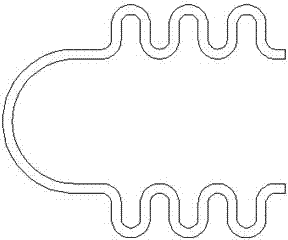

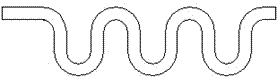

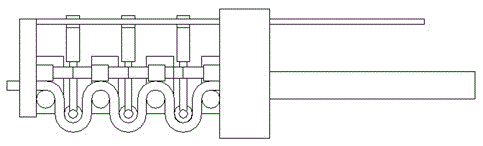

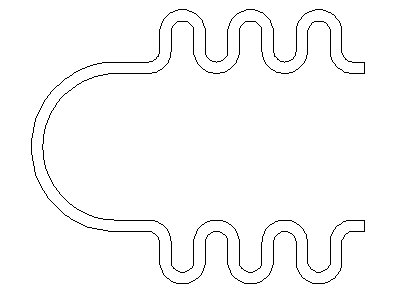

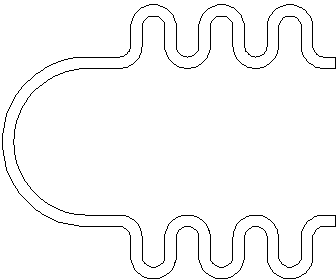

InactiveUS20120126067A1Easy and rapid transformationPrevent longitudinal deformationPipe supportsElectrical apparatusPlastic materialsEngineering

Device for routing cables, more particularly intended for routing and distributing electric cables having an elongated shape (1) with a U-shaped cross-section including an assembly of two side posts (3) forming the arms of the U and of a base (2) forming the bottom of the U. The side posts (3) and the base (2) are made from a composite material and / or a strengthened plastic material and in that at least one side post (3) is pivotally mounted while being jointed to the base (2) about an axis of rotation (30) by at least one hinge (4) and in that it comprises snap-coupling devices (35,26,63,7) and abutment devices (22,23,38,29,27) capable of locking the side post perpendicularly to said base (2) under the action of its rotation.

Owner:CQFD COMPOSITES

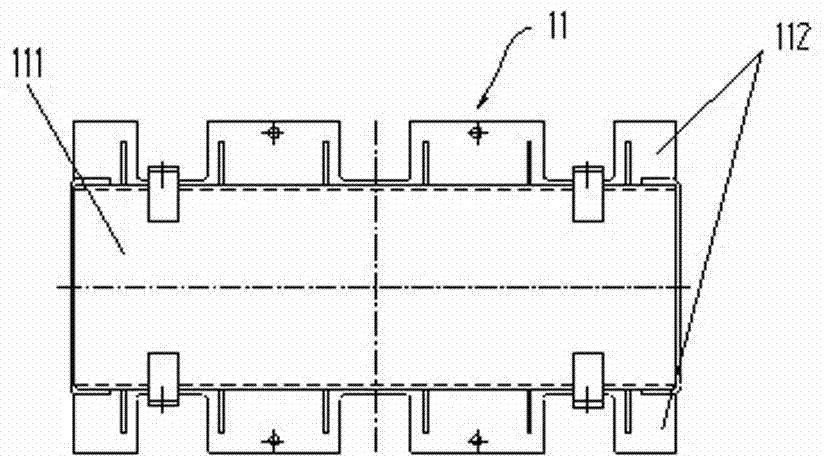

Transformer body structure

InactiveCN103050236AAchieve axial compressionIncrease axial pressureTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerFlux loop

The invention relates to a transformer body structure, in particular to a body structure of an open type winding iron core transformer. The transformer body structure comprises a magnetic flux loop formed by splicing multiple silicon steel sheets, an upper clamping part arranged on the upper portion of the magnetic flux loop, a lower clamping part arranged on the lower portion of the magnetic flux loop and two side plates positioned on the left and right sides of the body structure, the upper clamping part comprises an upper body and upper fixed plates fixedly arranged on the left and right sides of the upper body, the lower clamping part comprises a lower body and lower fixed plates fixedly arranged on the left and right sides of the lower body, the side plates are detachable and connected with the upper fixed plates and the lower fixed plates respectively, a storage space of the magnetic flux loop is formed among the upper clamping part, the two side plates and the lower clamping part, and a connecting mechanism capable of being in detachable connection is arranged between the upper clamping part and the lower clamping part. The transformer body structure is compact in structure, high in strength, small in noise and high in short-circuit resistance.

Owner:WUJIANG TRANSFORMER CO LTD

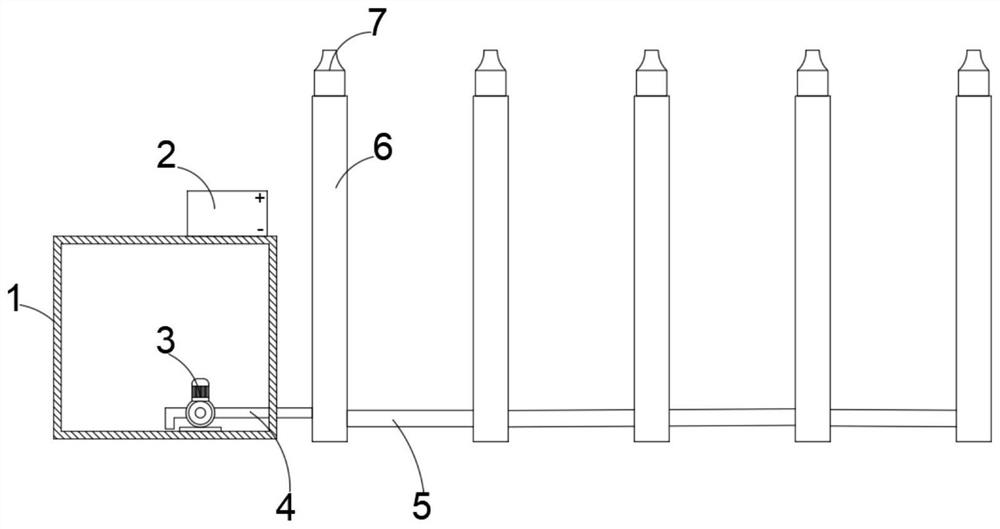

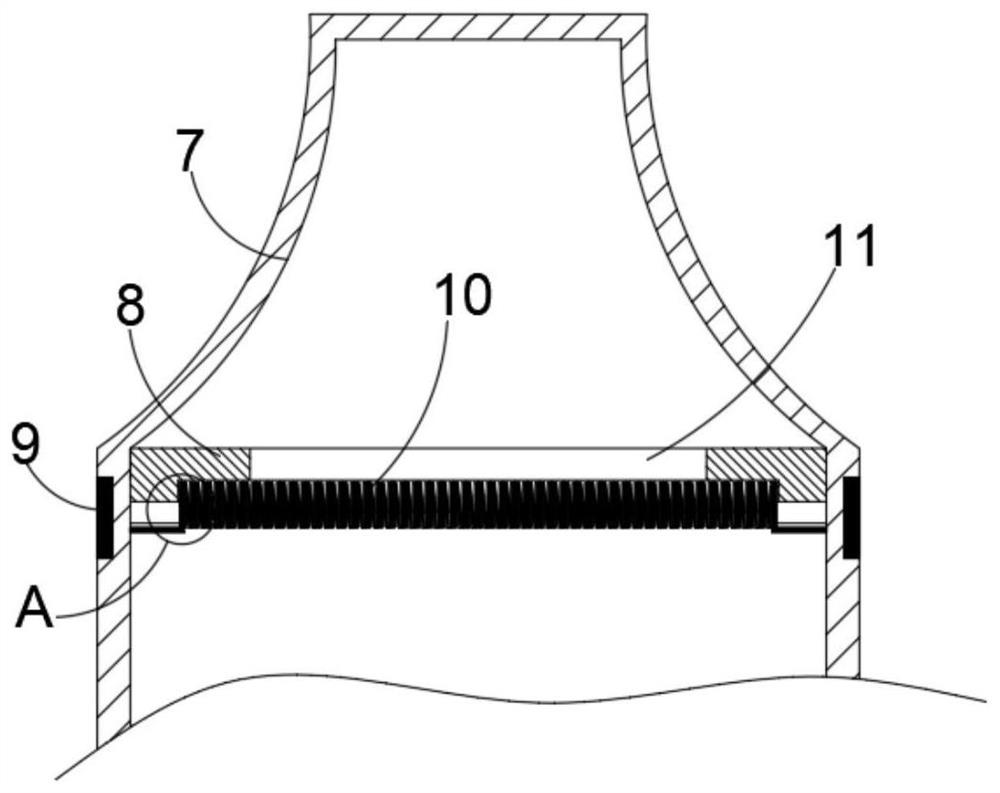

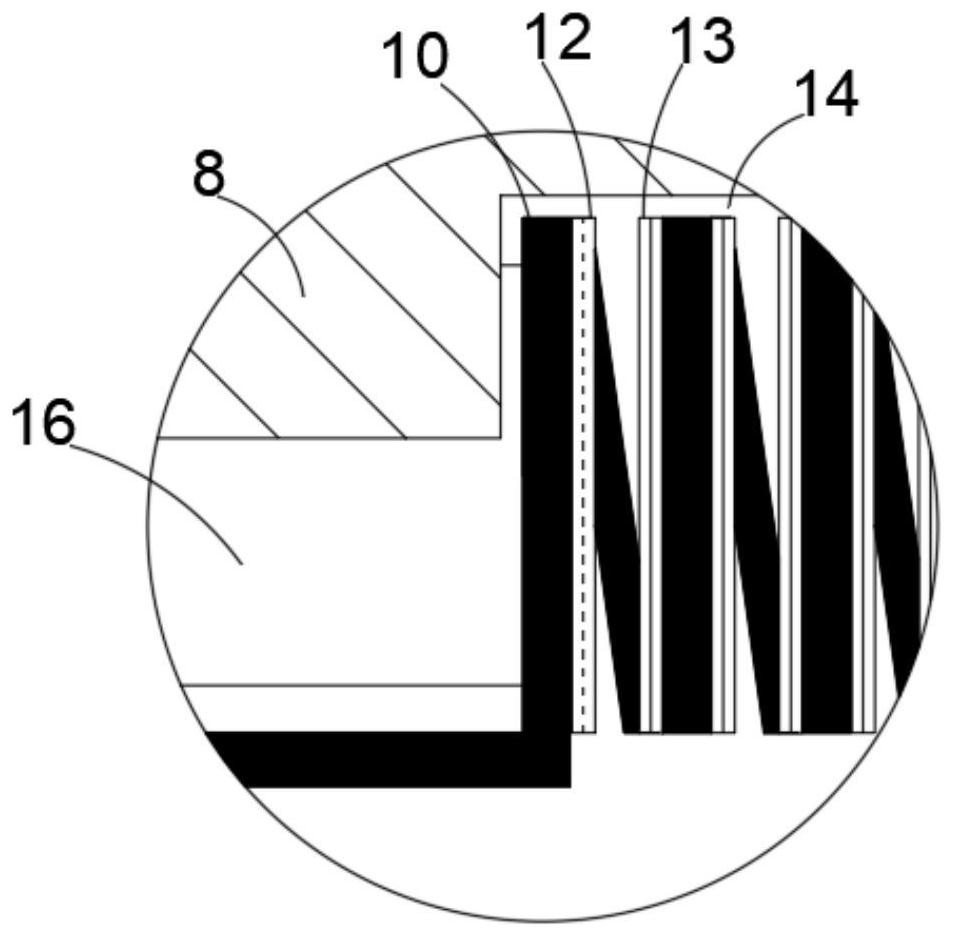

Novel high-sensitivity controllable sprinkler irrigation system

ActiveCN108966792AControl clearanceSatisfy traffic demandPressurised distribution of liquid fertiliserEngineeringTower

The invention discloses a novel high-sensitivity controllable sprinkler irrigation system. The novel high-sensitivity controllable sprinkler irrigation system comprises a water tower and a plurality of sprinkler irrigation pipes, wherein the sprinkler irrigation pipes are vertically arranged; the multiple sprinkler irrigation pipes are arranged in a communicated mode through connecting pipes whichare transversely arranged; the water tower is of a hollow structure; a water pump is arranged on the side wall of the lower side of the water tower; a water inlet pipe of the water pump is located atthe bottom of the water tower; a water outlet pipe of the water pump penetrates through the side wall of the water tower and is communicated with the side wall of one of the sprinkler irrigation pipes; sprinkler irrigation spray heads are arranged on the side walls of the upper sides of the sprinkler irrigation pipes; partition plates which are transversely arranged are arranged in the inner walls of the sprinkler irrigation spray heads; the side walls of the very centers of the partition plates are provided with strip-shaped water outlets which are transversely arranged; the side walls of the lower sides of the partition plates are provided with arc-shaped sliding grooves; and the arc-shaped sliding grooves are communicated with the strip-shaped water outlets. According to the novel high-sensitivity controllable sprinkler irrigation system, the flow of sprinkler irrigation can be strictly controlled, the flow adjusting precision is high, and the adjusting operation is time-saving andlabor-saving.

Owner:ANHUI KANGYU HYDROPOWER MACHINERY COMPLETE EQUIP CO LTD

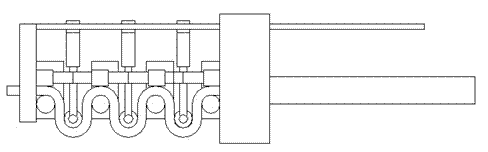

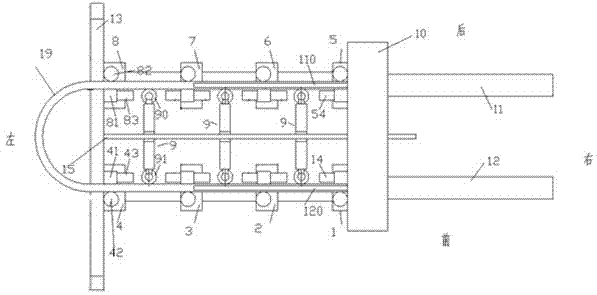

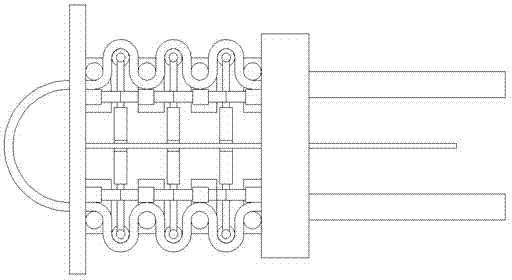

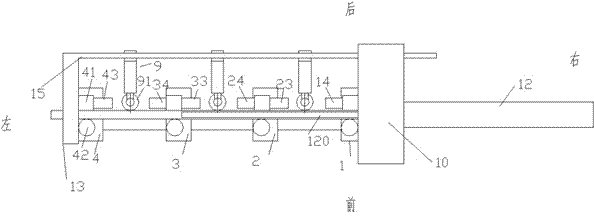

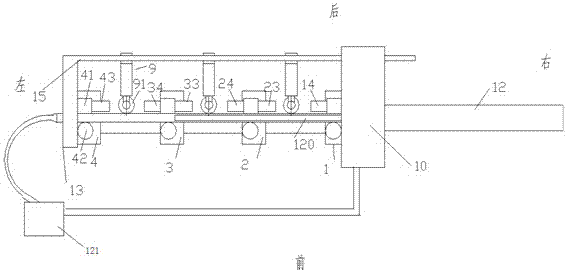

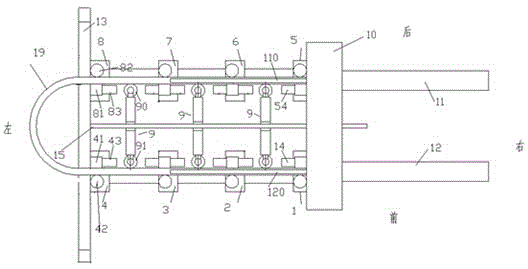

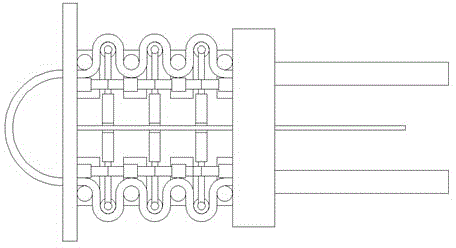

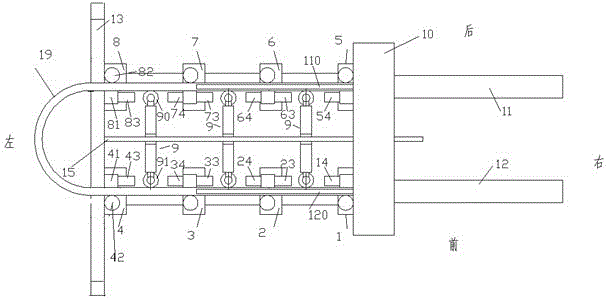

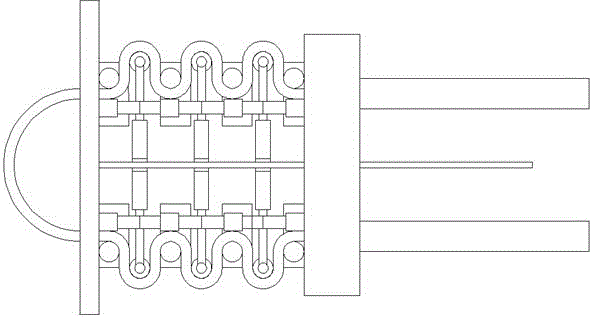

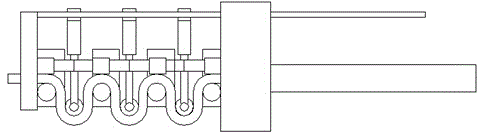

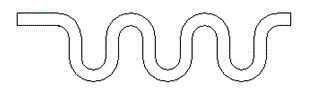

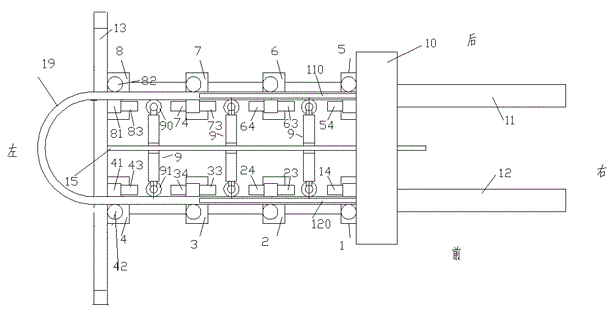

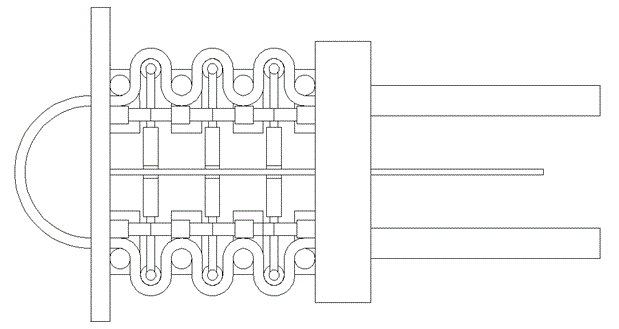

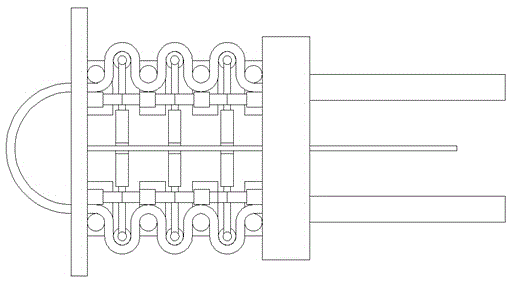

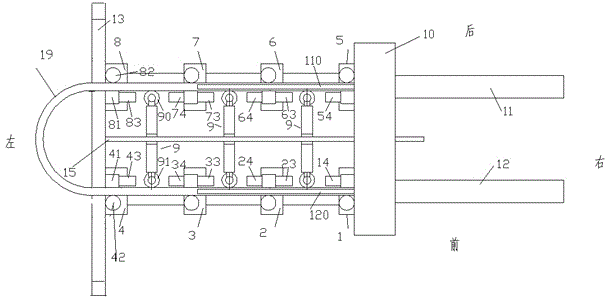

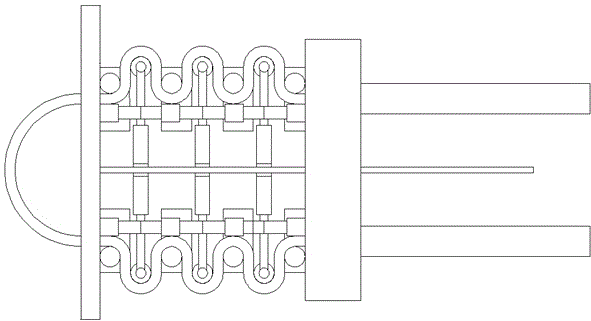

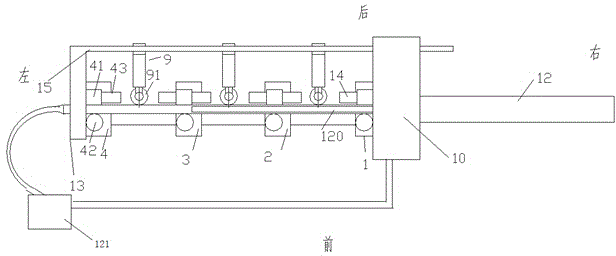

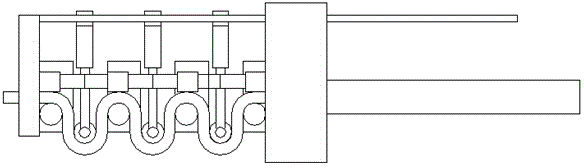

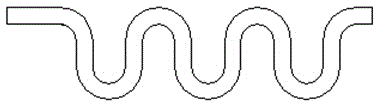

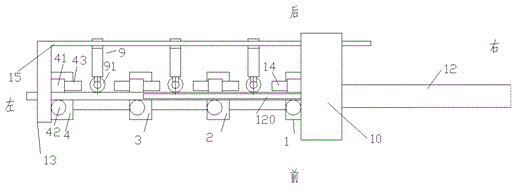

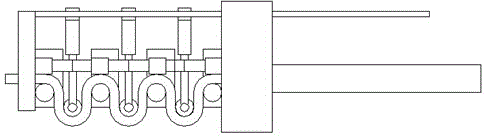

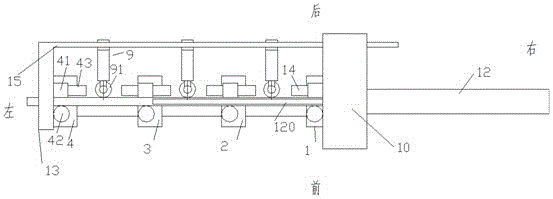

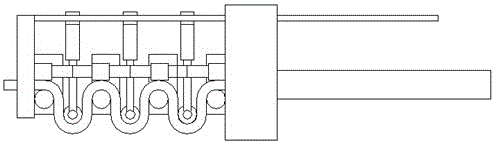

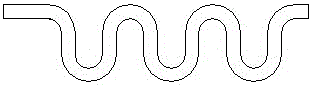

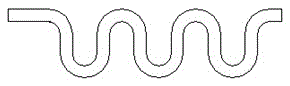

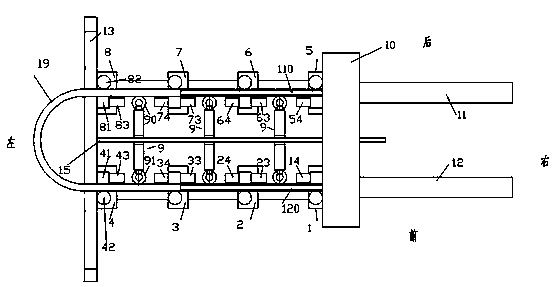

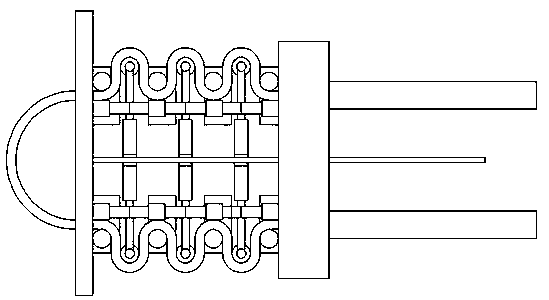

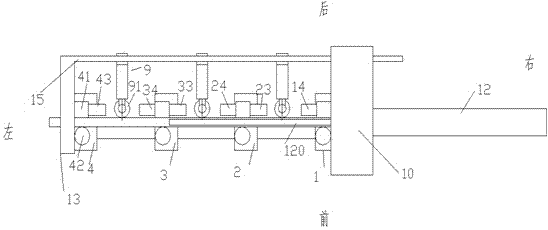

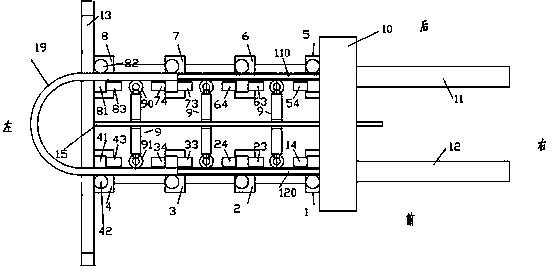

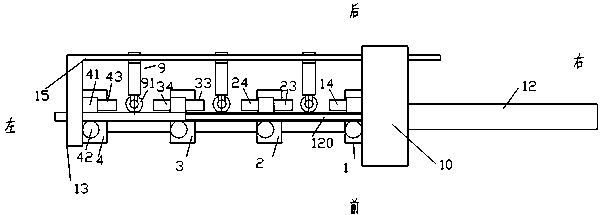

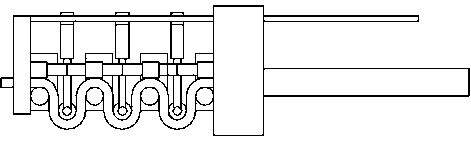

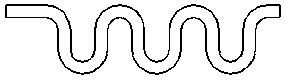

Bending technology for furnace tube of linear heating furnace

InactiveCN103920767AGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

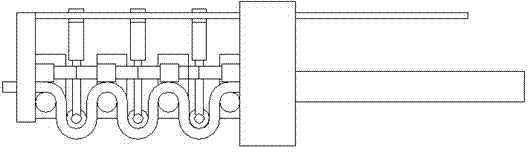

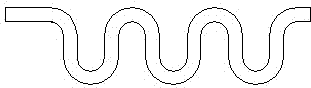

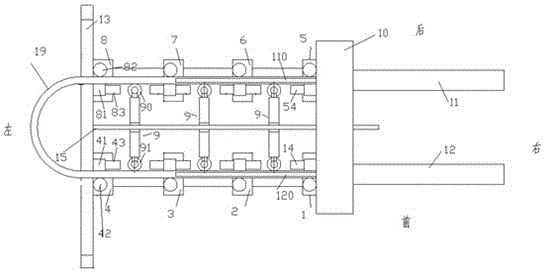

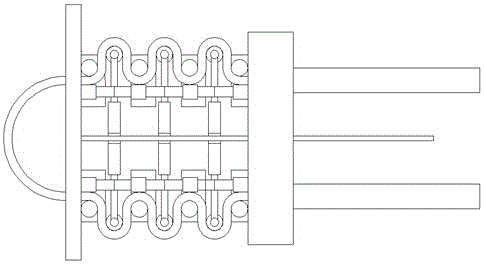

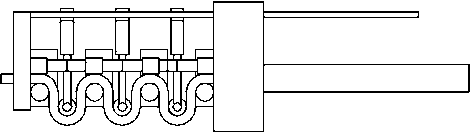

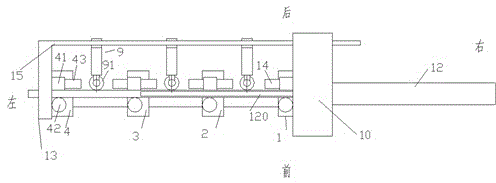

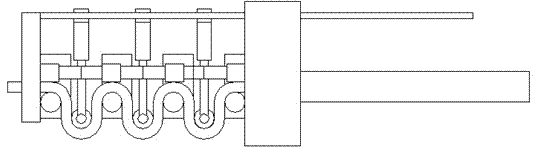

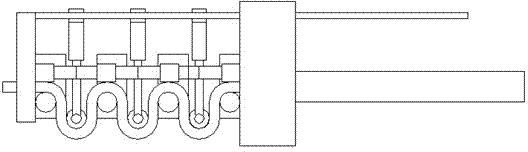

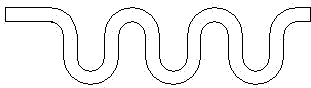

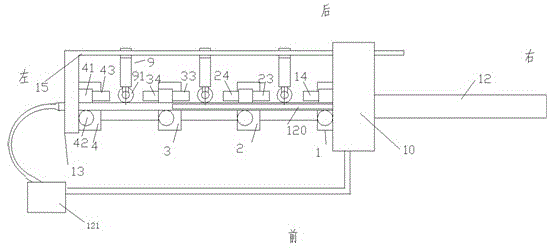

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:方自成

A New High Sensitivity Controllable Sprinkler Irrigation System

ActiveCN108966792BControl clearanceSatisfy traffic demandPressurised distribution of liquid fertiliserStream flowEnvironmental engineering

The invention discloses a novel high-sensitivity controllable sprinkler irrigation system, which includes a water tower and a plurality of vertically arranged sprinkler irrigation pipes. The plurality of sprinkler irrigation pipes are connected and arranged through horizontally arranged connecting pipes, and the water tower is a hollow structure. , and the lower side wall of the water tower is provided with a water pump, the inlet pipe of the water pump is located at the bottom of the water tower, and the outlet pipe of the water pump runs through the side wall of the water tower and communicates with the side wall of one of the sprinkler pipes, the The upper side wall of the sprinkler pipe is provided with a sprinkler nozzle, and the inner wall of the sprinkler nozzle is provided with a horizontal partition, and the central side wall of the partition is provided with a horizontal strip water outlet. An arc-shaped chute is arranged on the lower side wall of the dividing plate, and the arc-shaped chute communicates with the bar-shaped water outlet. In the present invention, the novel high-sensitivity controllable sprinkler irrigation system can strictly control the flow rate of sprinkler irrigation, has high flow rate adjustment accuracy, and saves time and labor in the adjustment operation.

Owner:ANHUI KANGYU HYDROPOWER MACHINERY COMPLETE EQUIP CO LTD

Bending technology for furnace tube of linear heating furnace

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:海门江海建设投资有限公司

U-shape Furnace Tube Bending Process Using Fixture Locking Rail Mechanism and Carrying out Pressure Keeping and Sizing

InactiveCN103894463BGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

Owner:南通市海门江海建设投资有限公司

Bending Process of a Linear Heating Furnace Tube

InactiveCN103934331BGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

The invention discloses a linear type heating furnace tube bending technology. According to the technology, a furnace tube bending device is used and comprises a left machine frame (13) and a pushing and pressing mechanism (10), the pushing and pressing mechanism (10) is located on the right side of the left machine frame (13), a dovetail guide rail (15) is fixedly connected to the rear portion of the right side of the left machine frame (13) and extends horizontally in the left-right direction, the left end of the dovetail guide rail (15) is fixedly connected with the left machine frame (13), the right end of the dovetail guide rail (15) is in sliding connection with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing a furnace tube to penetrate through is formed in the front portion of the left machine frame (13), and three hydraulic bending devices (9) are arranged on the dovetail guide rail (15) from left to right in sequence in a sliding mode and located between the left machine frame (13) and the pushing and pressing mechanism (10).

Owner:董璞玉

Bending technology for furnace tube of linear heating furnace

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:南通江海港建设工程有限公司

Bending Process of a Linear Heating Furnace Tube

The invention discloses a linear type heating furnace tube bending technology. According to the technology, a furnace tube bending device is used and comprises a left machine frame (13) and a pushing and pressing mechanism (10), the pushing and pressing mechanism (10) is located on the right side of the left machine frame (13), a dovetail guide rail (15) is fixedly connected to the rear portion of the right side of the left machine frame (13) and extends horizontally in the left-right direction, the left end of the dovetail guide rail (15) is fixedly connected with the left machine frame (13), the right end of the dovetail guide rail (15) is in sliding connection with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing a furnace tube to penetrate through is formed in the front portion of the left machine frame (13), and three hydraulic bending devices (9) are arranged on the dovetail guide rail (15) from left to right in sequence in a sliding mode and located between the left machine frame (13) and the pushing and pressing mechanism (10).

Owner:徐州博创建设发展集团有限公司

U-shape Furnace Tube Bending Process Using Fixture Locking Rail Mechanism and Fixture Position Sensor

ActiveCN103861922BGuaranteed shape accuracyAvoid insufficient clamping forceLocking mechanismEngineering

The invention discloses a U-shaped heating furnace tube bending technology which uses furnace tube bending equipment. The furnace tube bending equipment comprises a left machine frame and a pushing and pressing mechanism, wherein the pushing and pressing mechanism is located on the right side of the left machine frame, a guide rod is fixedly arranged in the middle of the right side of the left machine frame and extends horizontally in the left-right direction, the left end of the guide rod is fixedly connected with the left machine frame, the right end of the guide rod is connected with the middle of the pushing and pressing mechanism in a sliding mode, a channel used for allowing an original U-shaped furnace tube to pass through to be fed and a well machined furnace tube to pass through to be discharged is formed in the left machine frame, and three bending hydraulic devices are arranged on the guide rod and between the left machine frame and the pushing and pressing mechanism in a sliding mode in sequence from left to right.

Owner:郎溪品旭科技发展有限公司

Bending process of u-shaped furnace tube using bending roll distance sensor and pressure-holding finalization

Owner:XUZHOU MASTER MECHANICAL TECH CO LTD

U-shaped furnace pipe bending process for carrying out heating fluid heating and carrying out ejection and material returning

InactiveCN103846325BGuaranteed shape accuracyAvoid insufficient clamping forceMetal-working feeding devicesPositioning devicesEngineeringMachining process

Owner:广州市火龙焊接设备有限公司

Linear type heating furnace tube bending technology

InactiveCN103934332AGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringHeating furnace

The invention discloses a linear type heating furnace tube bending technology. According to the technology, a furnace tube bending device is used and comprises a left machine frame (13) and a pushing and pressing mechanism (10), the pushing and pressing mechanism (10) is located on the right side of the left machine frame (13), a dovetail guide rail (15) is fixedly connected to the rear portion of the right side of the left machine frame (13) and extends horizontally in the left-right direction, the left end of the dovetail guide rail (15) is fixedly connected with the left machine frame (13), the right end of the dovetail guide rail (15) is in sliding connection with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing a furnace tube to penetrate through is formed in the front portion of the left machine frame (13), and three hydraulic bending devices (9) are arranged on the dovetail guide rail (15) from left to right in sequence in a sliding mode and located between the left machine frame (13) and the pushing and pressing mechanism (10).

Owner:HUAIAN KANGNUOKE COLOR PRINTING

Bending Process of a Linear Heating Furnace Tube

ActiveCN103934333BGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringHeating furnace

The invention discloses a linear type heating furnace tube bending technology. According to the technology, a furnace tube bending device is used and comprises a left machine frame (13) and a pushing and pressing mechanism (10), the pushing and pressing mechanism (10) is located on the right side of the left machine frame (13), a dovetail guide rail (15) is fixedly connected to the rear portion of the right side of the left machine frame (13) and extends horizontally in the left-right direction, the left end of the dovetail guide rail (15) is fixedly connected with the left machine frame (13), the right end of the dovetail guide rail (15) is in sliding connection with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing a furnace tube to penetrate through is formed in the front portion of the left machine frame (13), and three hydraulic bending devices (9) are arranged on the dovetail guide rail (15) from left to right in sequence in a sliding mode and located between the left machine frame (13) and the pushing and pressing mechanism (10).

Owner:JIANGSU BINXIN STEEL GRP

U-shaped heating furnace tube bend process for conducting heating fluid heating and pressure maintaining forming

Disclosed is a U-shaped heating furnace tube bend machining technology. Furnace tube bending equipment is used, the furnace tube bending equipment comprises a left rack and a pushing mechanism, and the pushing mechanism is arranged on the right side of the left rack. A guide rod is fixedly arranged in the middle part of the right side of the left rack, and the guide rod extends horizontally in the left-right direction. The left end of the guide rod is fixedly connected with the left rack, the right end of the guide rod is connected with the middle of the pushing mechanism in a sliding mode, and a channel used for allowing an original U-shaped furnace tube to be fed and to penetrate through and allowing a machined furnace tube to be discharged and to pass through is formed in the left rack. Three bending hydraulic devices are sequentially arranged from left to right in a sliding mode on the guide rod between the left rack and the pushing mechanism.

Owner:JIANGSU JINSHENGYUAN SPECIAL VALVE

U-shaped furnace tube bending process for stress relief heat treatment and pressure maintaining and finalizing

InactiveCN103861919BGuaranteed shape accuracyAvoid insufficient clamping forceStress relievingEngineering

The invention provides a bending technology for U-shaped heating furnace tubes. According to the bending technology, a furnace tube bending device is applied. The furnace tube bending device comprises a left machine frame and a pushing and pressing mechanism, wherein the pushing and pressing mechanism is located on the right side of the left machine frame, a guide rod is fixedly arranged at the middle position of the right side of the left machine frame, the guide rod horizontally extends leftwards and rightwards, the left end of the guide rod is fixedly connected with the left machine frame, and the right end of the guide rod is connected with the middle portion of the pushing and pressing mechanism in a sliding mode. A channel is arranged in the left machine frame, and the channel is used for feeding and penetrating of original U-shaped furnace tubes and discharging of the machined furnace tubes. Three bending hydraulic devices are sequentially arranged on the portion, between the left machine frame and the pushing and pressing mechanism, of the guide rod from left to right in a sliding mode.

Owner:江苏振强不锈钢制品有限公司

U-shape Furnace Tube Bending Process Using Bending Roll Distance Sensor and Stress Relief Heat Treatment

InactiveCN103861909BGuaranteed shape accuracyAvoid insufficient clamping forceMetal-working feeding devicesPositioning devicesEngineeringTube bending

Owner:扬州市金川表面处理有限公司

Bending Process of a Linear Heating Furnace Tube

InactiveCN103920772BGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:扬州市金川表面处理有限公司

Bending process of a straight heating furnace tube

Owner:JIANGSU BINXIN STEEL GRP

Bending Process of a Linear Heating Furnace Tube

The invention discloses a linear type heating furnace tube bending technology. According to the technology, a furnace tube bending device is used and comprises a left machine frame (13) and a pushing and pressing mechanism (10), the pushing and pressing mechanism (10) is located on the right side of the left machine frame (13), a dovetail guide rail (15) is fixedly connected to the rear portion of the right side of the left machine frame (13) and extends horizontally in the left-right direction, the left end of the dovetail guide rail (15) is fixedly connected with the left machine frame (13), the right end of the dovetail guide rail (15) is in sliding connection with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing a furnace tube to penetrate through is formed in the front portion of the left machine frame (13), and three hydraulic bending devices (9) are arranged on the dovetail guide rail (15) from left to right in sequence in a sliding mode and located between the left machine frame (13) and the pushing and pressing mechanism (10).

Owner:JIANGSU BINXIN STEEL GRP

Bending technology for furnace tube of linear heating furnace

InactiveCN103920772AGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringHeating furnace

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:扬州市金川表面处理有限公司

Bending technology for furnace tube of linear heating furnace

ActiveCN103920774BGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringHeating furnace

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:南通江海港建设工程有限公司

Bending Process of a Linear Heating Furnace Tube

InactiveCN103920767BGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:方自成

U-shaped furnace tube bending process adopting clamp rail locking mechanism and carrying out distressing heat treatment

ActiveCN103861920AGuaranteed shape accuracyAvoid insufficient clamping forceLocking mechanismEngineering

The invention relates to a U-shaped heating furnace tube bending machining process. Furnace tube bending equipment is adopted by the process and comprises a left rack and a pushing and pressing mechanism, the pushing and pressing mechanism is arranged on the right side of the left rack, a guide rod is fixedly arranged in the middle of the right side of the left rack, the guide rod horizontally extends in the left-and-right direction, the left end of the guide rod is fixedly connected with the left rack, the right end of the guide rod is in sliding connection with the middle of the pushing and pressing mechanism, and a channel which allows an original fed U-shaped furnace tube to pass and allows a discharged machined furnace tube to pass is arranged in the left rack. Three bending hydraulic devices are sequentially arranged at the position, between the left rack and the pushing and pressing mechanism, of the guide rod from left to right in a sliding mode.

Owner:南通泰东机械有限公司

Bending Process of a Linear Heating Furnace Tube

InactiveCN103920770BGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

Owner:RUGAO OUTONG MACHINERY FITTINGS

Bending technology for furnace tube of linear heating furnace

InactiveCN103920770AGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:RUGAO OUTONG MACHINERY FITTINGS

U-shaped furnace tube bending technology for distressing thermal treatment and pressure-maintaining shaping

InactiveCN103861919AGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

The invention provides a bending technology for U-shaped heating furnace tubes. According to the bending technology, a furnace tube bending device is applied. The furnace tube bending device comprises a left machine frame and a pushing and pressing mechanism, wherein the pushing and pressing mechanism is located on the right side of the left machine frame, a guide rod is fixedly arranged at the middle position of the right side of the left machine frame, the guide rod horizontally extends leftwards and rightwards, the left end of the guide rod is fixedly connected with the left machine frame, and the right end of the guide rod is connected with the middle portion of the pushing and pressing mechanism in a sliding mode. A channel is arranged in the left machine frame, and the channel is used for feeding and penetrating of original U-shaped furnace tubes and discharging of the machined furnace tubes. Three bending hydraulic devices are sequentially arranged on the portion, between the left machine frame and the pushing and pressing mechanism, of the guide rod from left to right in a sliding mode.

Owner:江苏振强不锈钢制品有限公司

Linear type heating furnace tube bending technology

The invention discloses a linear type heating furnace tube bending technology. According to the technology, a furnace tube bending device is used and comprises a left machine frame (13) and a pushing and pressing mechanism (10), the pushing and pressing mechanism (10) is located on the right side of the left machine frame (13), a dovetail guide rail (15) is fixedly connected to the rear portion of the right side of the left machine frame (13) and extends horizontally in the left-right direction, the left end of the dovetail guide rail (15) is fixedly connected with the left machine frame (13), the right end of the dovetail guide rail (15) is in sliding connection with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing a furnace tube to penetrate through is formed in the front portion of the left machine frame (13), and three hydraulic bending devices (9) are arranged on the dovetail guide rail (15) from left to right in sequence in a sliding mode and located between the left machine frame (13) and the pushing and pressing mechanism (10).

Owner:JIANGSU BINXIN STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com