Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Avoid repeated deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Panel processing method using vacuum chucks, left limiting sensor and right limiting sensor

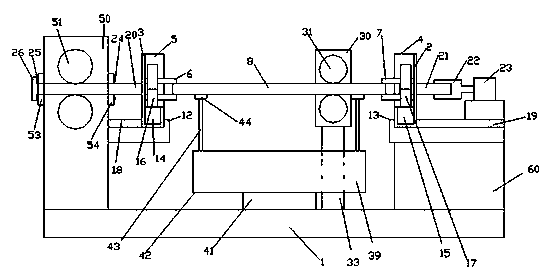

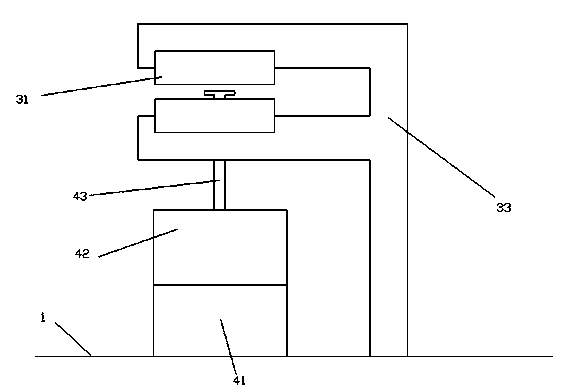

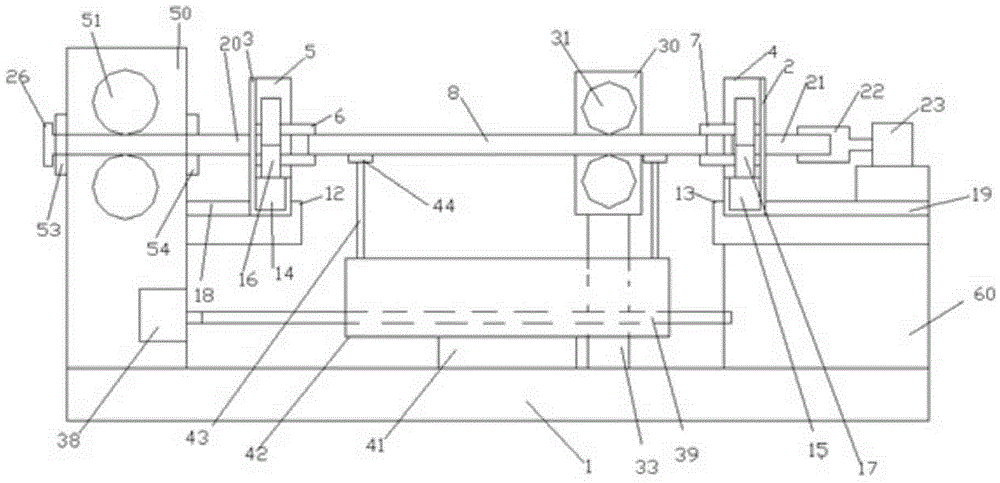

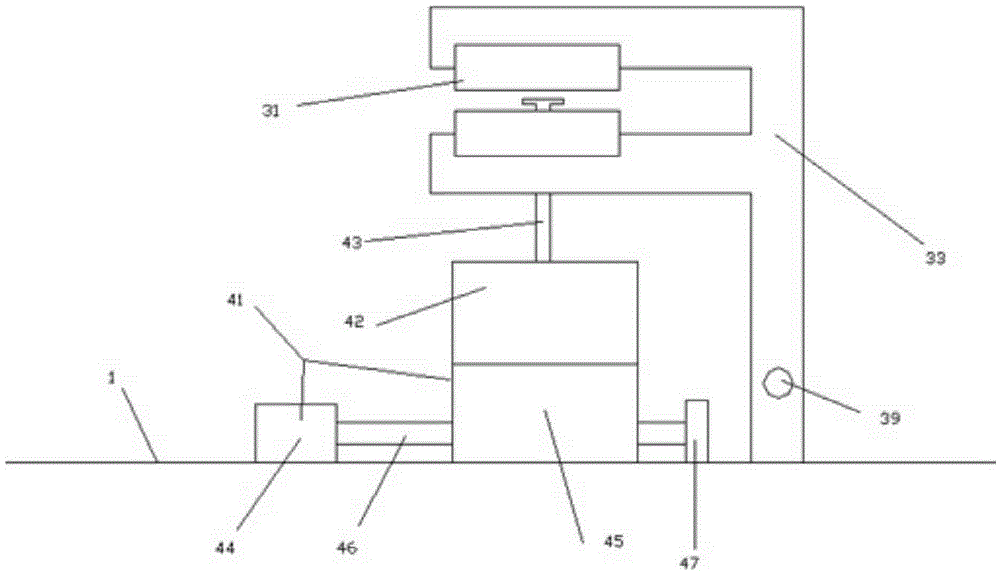

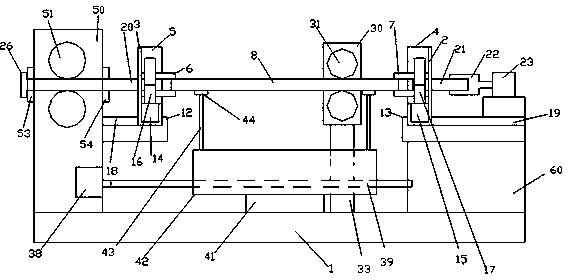

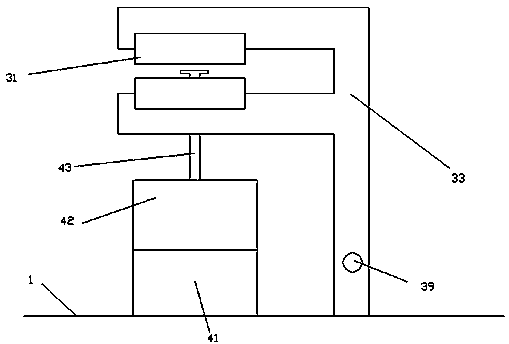

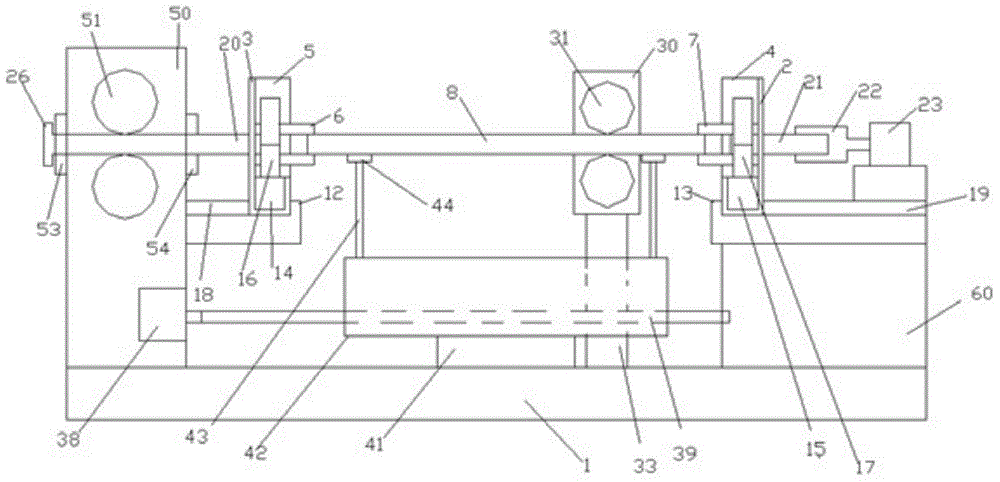

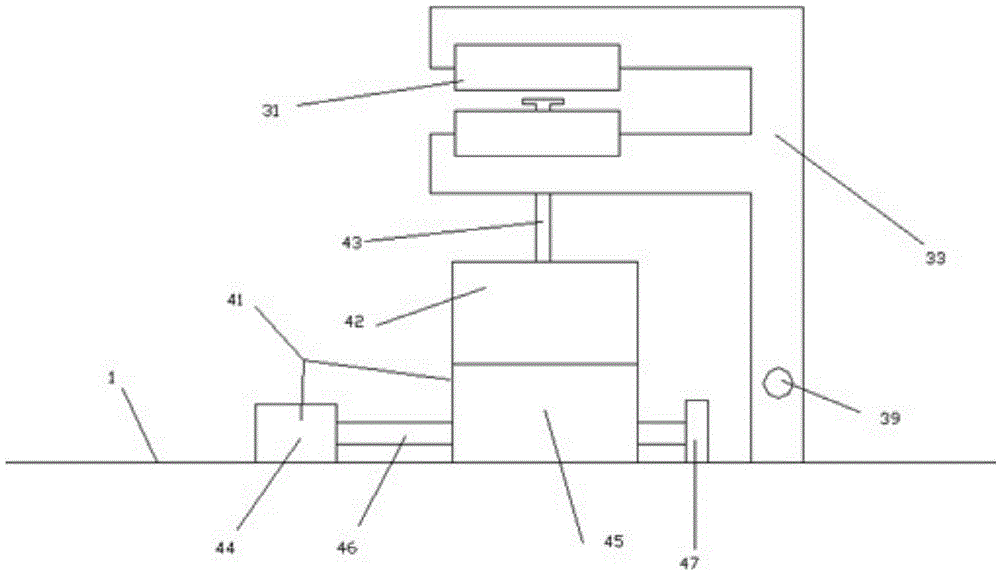

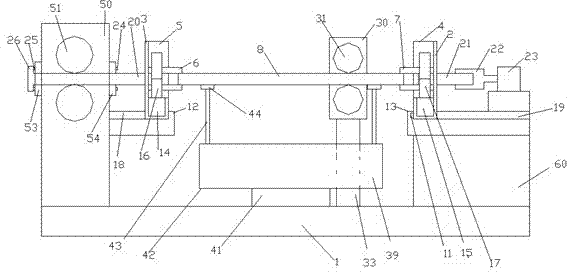

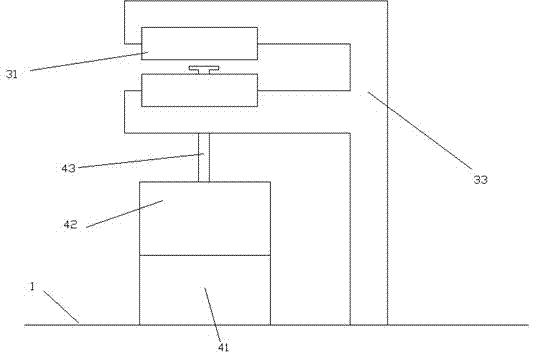

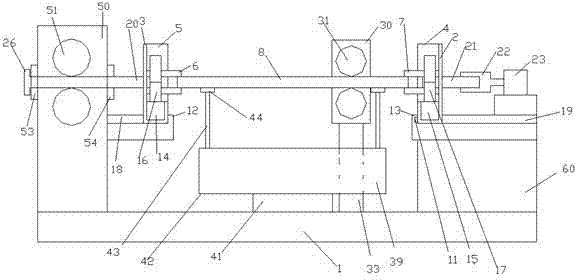

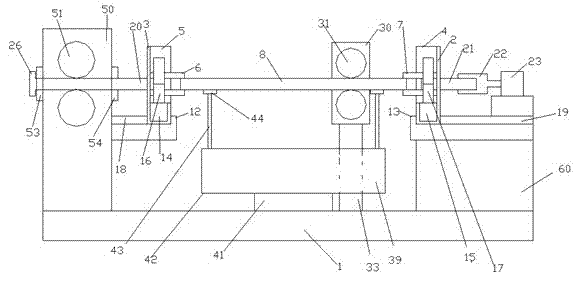

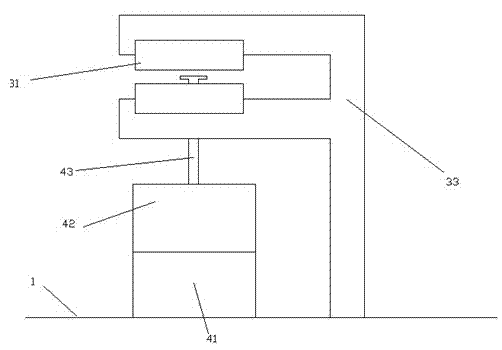

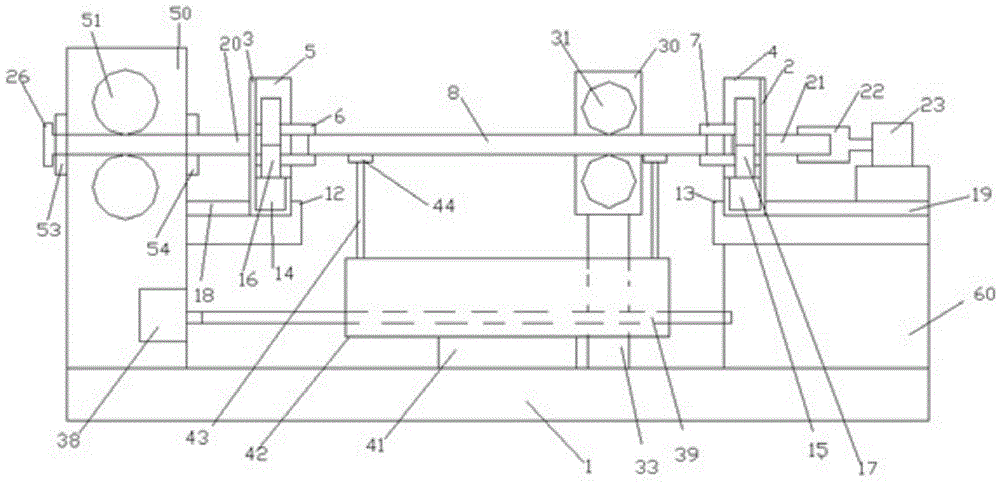

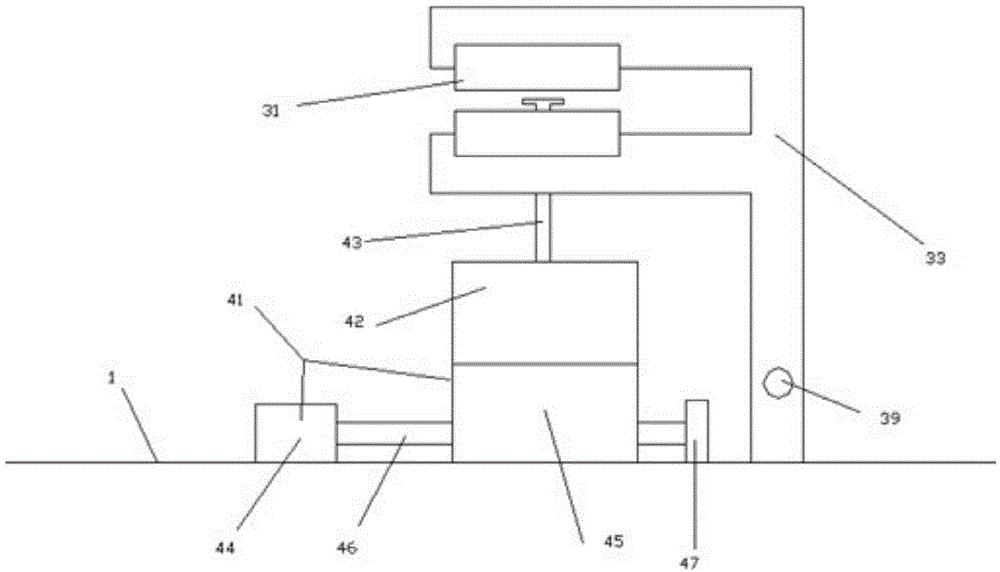

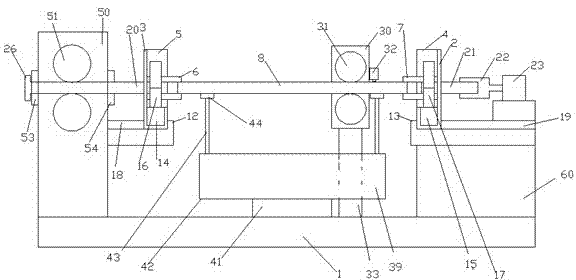

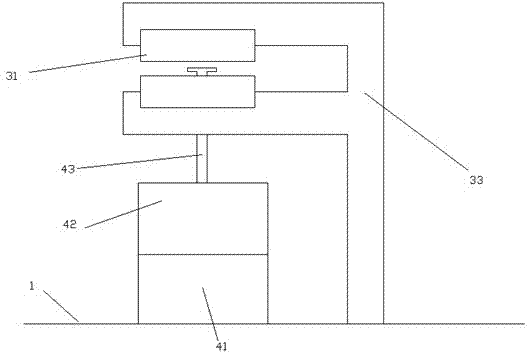

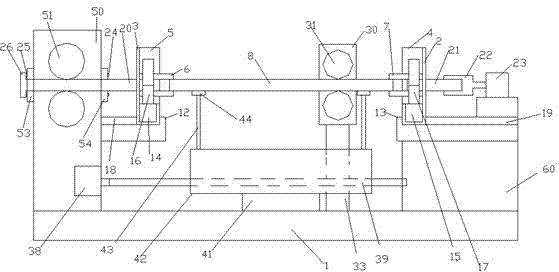

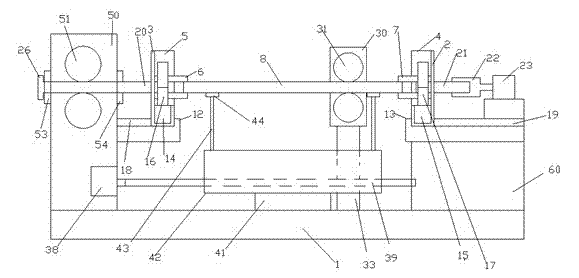

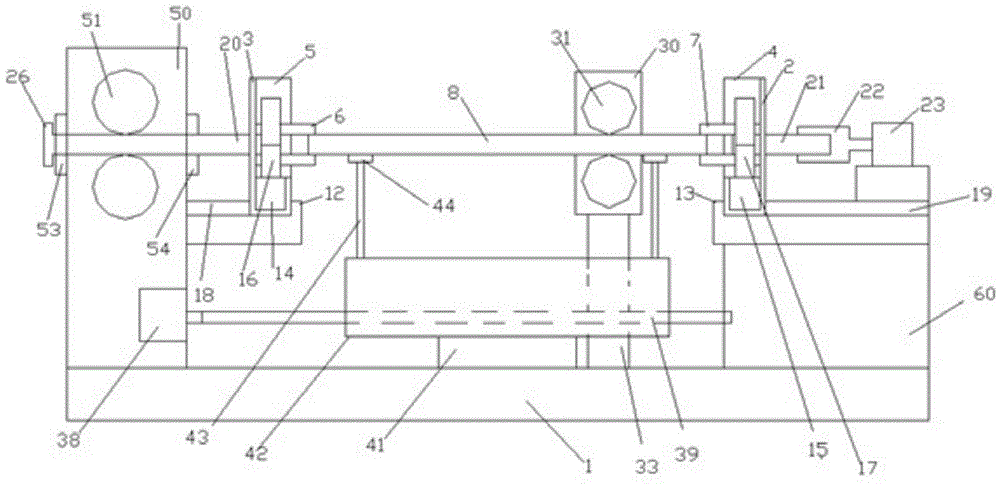

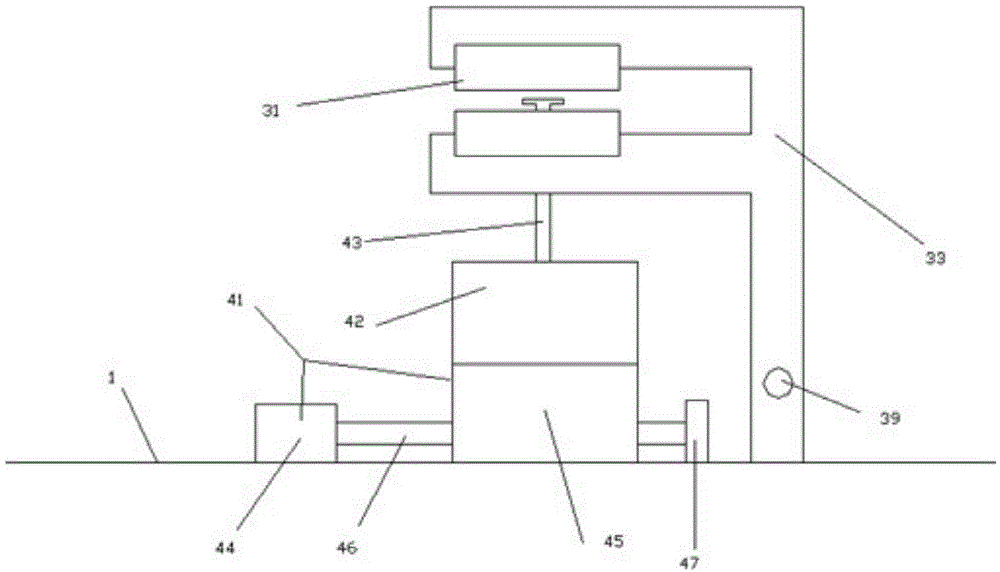

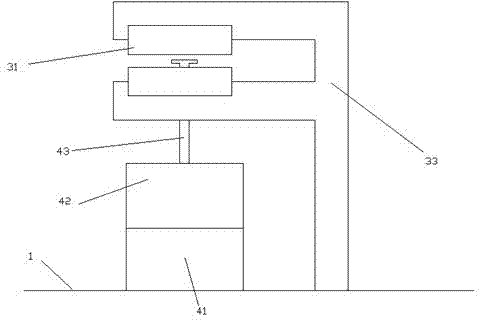

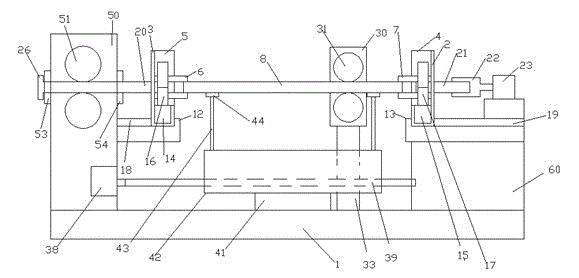

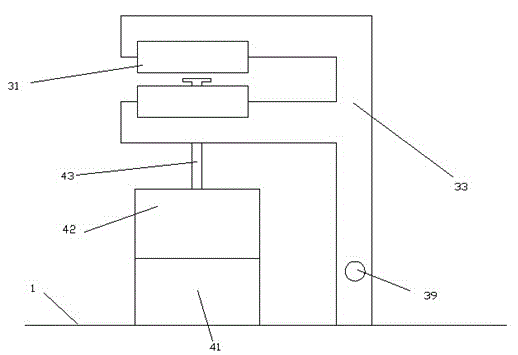

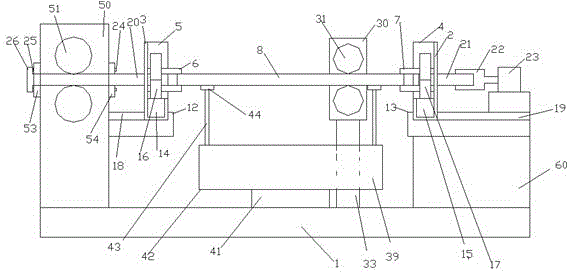

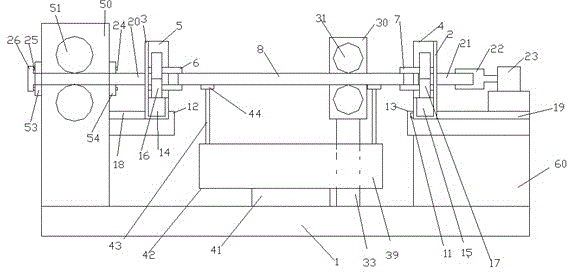

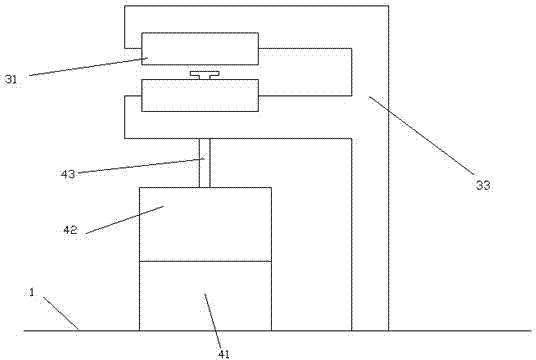

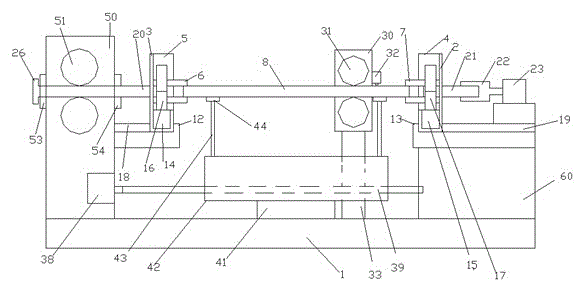

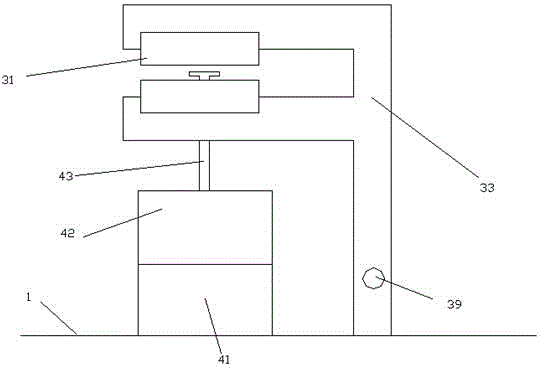

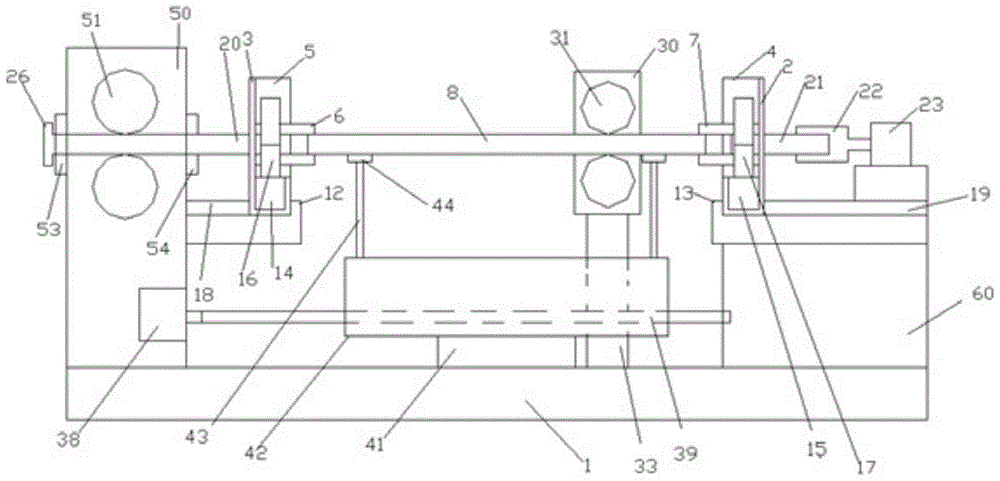

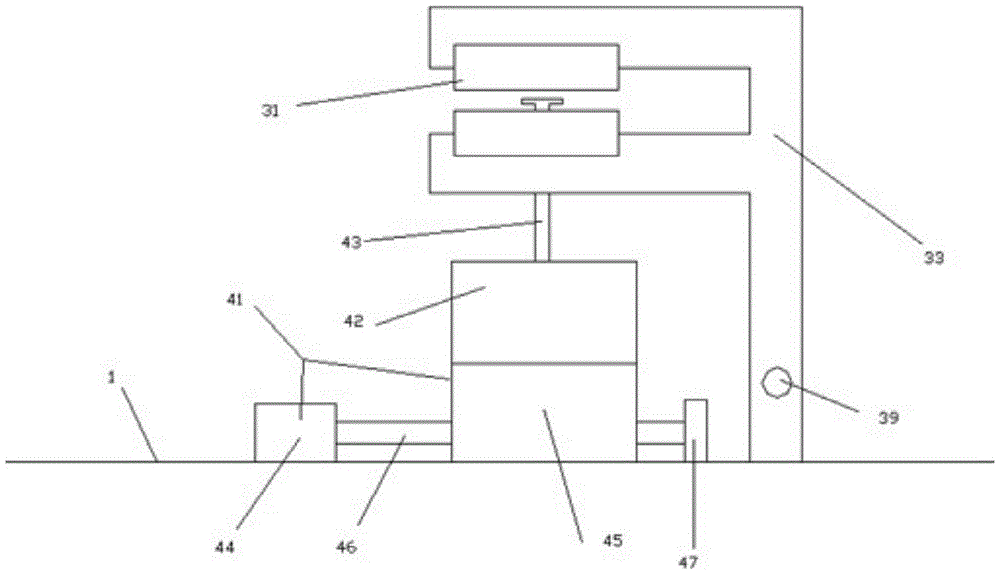

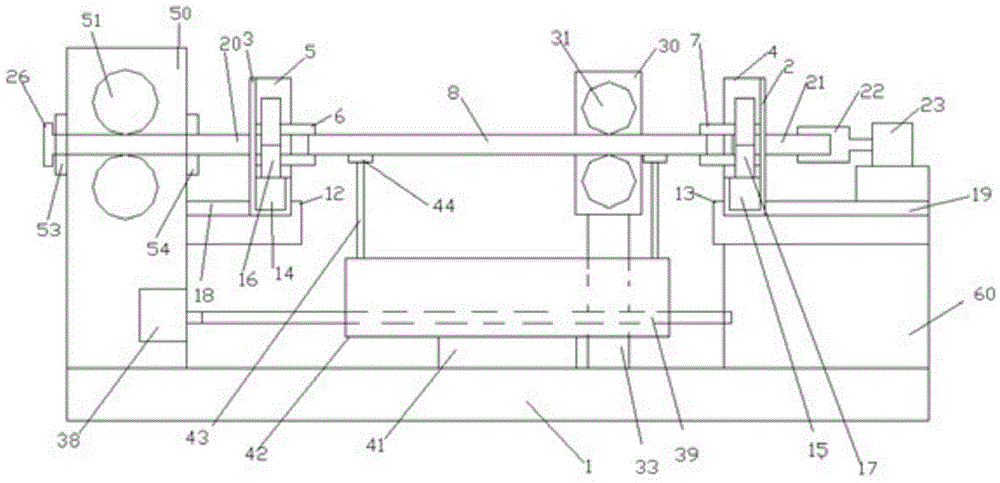

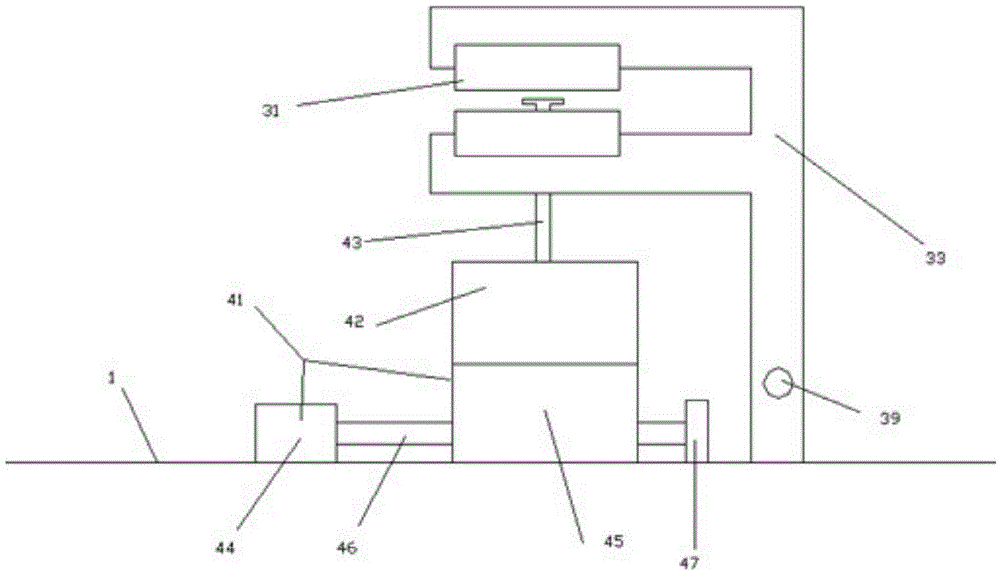

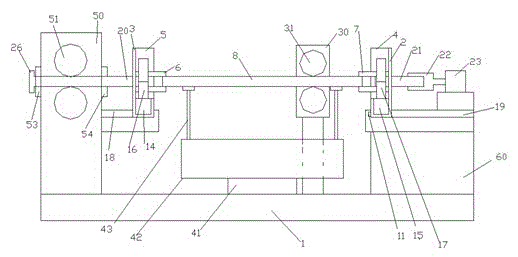

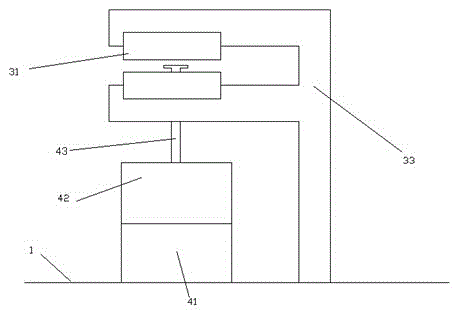

The invention discloses a panel processing method using vacuum chucks, a left limiting sensor and a right limiting sensor. Devices used in the panel processing method comprise an underbed, a left rack and a right rack, wherein the left rack is arranged at the left end of the underbed, the right rack is arranged at the right end of the underbed, a panel conveying device and a rolling device are arranged between the left end and the right end of the underbed, panels borne by the panel conveying device can move on the underbed in the front and back direction through the panel conveying device, the rolling device can slide on the underbed in the left and right direction, and the front and back direction is the direction which is perpendicular to the left and right direction in a horizontal plane; the panel conveying device comprises a bearing frame, a lifting device and a front and back direction sliding device, and when processing is carried out, the bearing frame is used for bearing the panels, the bearing frame is connected with the lifting device, the bearing frame can ascend and descend through the lifting device, and therefore the vertical positions of the panels can be adjusted when the panels are borne by the bearing frame.

Owner:海安江理工技术转移中心有限公司

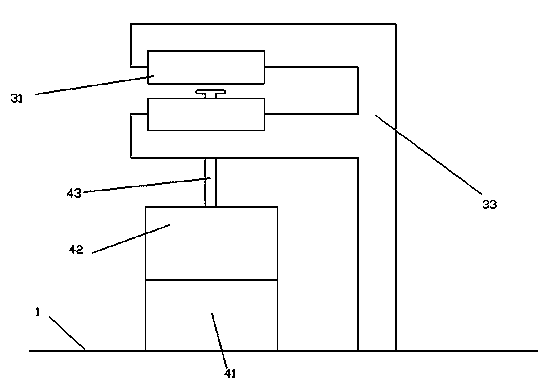

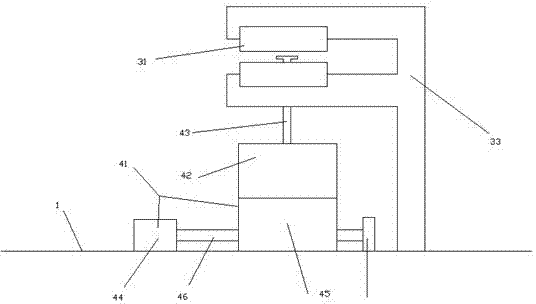

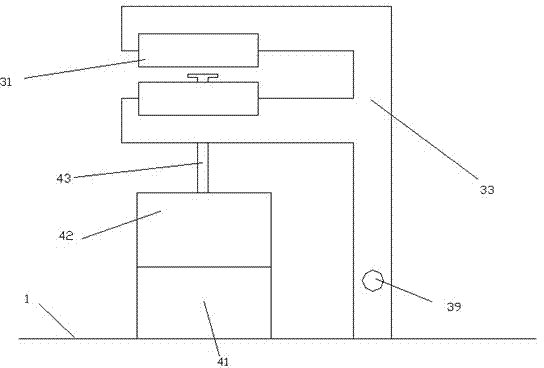

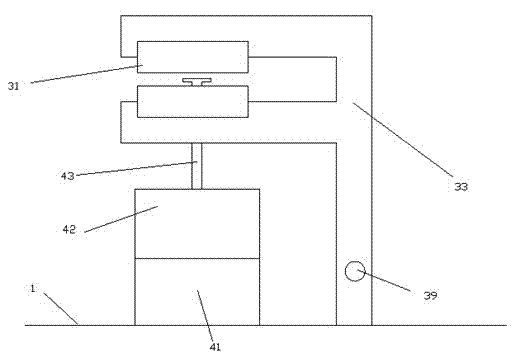

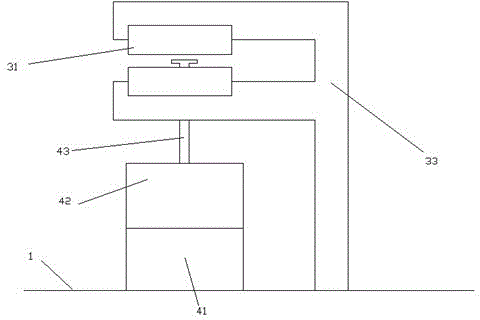

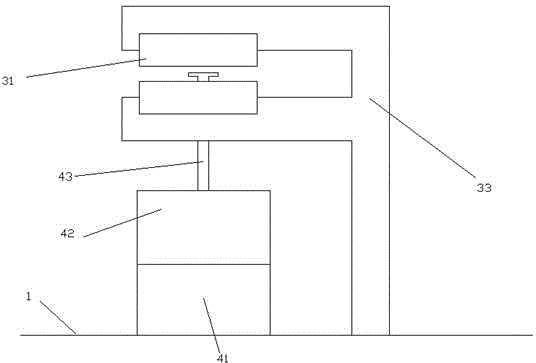

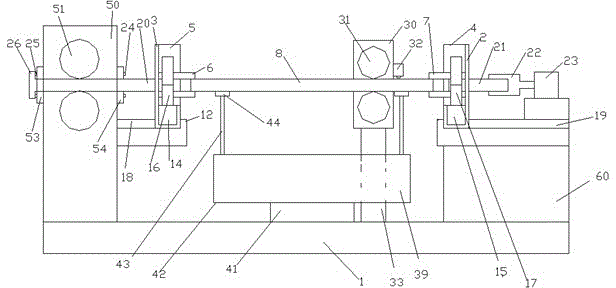

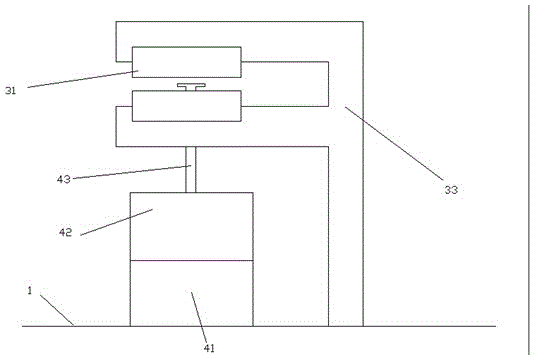

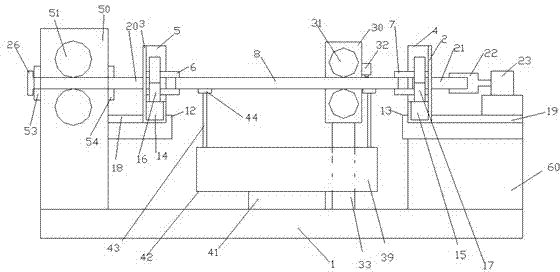

Plate processing device capable of preventing surfaces of plates from being wrinkled

The invention relates to a plate processing device. The plate processing device comprises a bottom rack, a plate conveying device and a rolling device, wherein plates on the plate conveying device can move on the bottom rack along the front-back direction with the aid of the plate conveying device; the rolling device can slide on the bottom rack along the left-right direction; the plate conveying device comprises a bearing rack, a lifting device and a front-back direction sliding device; the bearing rack is used for bearing the plates and is connected with the lifting device; the bearing rack can ascend or descend with the aid of the lifting device, so that the up-down positions of the plates can be adjusted when the plates are placed on the bearing rack; the lifting device is connected with the front-back direction sliding device; the rolling device comprises an upper cantilever roll and a lower cantilever roll; the plates can be driven by the plate conveying device to extend in space between the upper cantilever roll and the lower cantilever roll; the two cantilever rolls can apply a clamping force on the plates; and the plates can be subjected to rolling processing when the rolling device slides along the left-right direction.

Owner:七彩人生集团有限公司

Plate machining method using left-and-right moving lead screw and being capable of pressing lines

ActiveCN103802188AGuaranteed straightnessAvoid wrinklesWood working apparatusMachineMachining process

Disclosed is a plate machining method using a left-and-right moving lead screw and being capable of pressing lines. Devices used in the method comprise a base frame, a left machine frame and a right machine frame, the left machine frame is arranged at the left end of the base frame, the right machine frame is arranged at the right end of the base frame, a plate conveying device and a rolling device are arranged between the left end and the right end of the base frame, the plate conveying device enables borne plates to move on the base frame in the front-and-back direction, the rolling device can slide on the base frame in the left-and-right direction, and the front-and-back direction is perpendicular to the left-and-right direction in the horizontal plane. The plate conveying device comprises a bearing frame, a lifting device and a front-and-back sliding device, in the machining process, the bearing frame is used for bearing plates, the bearing frame is connected with the lifting device, the lifting device can lift the bearing frame, and therefore when the plates are borne, the vertical positions of the plates can be adjusted.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Sheet processing device capable of obtaining elaborate plate surface quality

The invention relates to a sheet processing device. The sheet processing device comprises an underframe, a sheet transporter and a rolling device; the sheet transporter is capable of enabling the carried sheets to move on the underframe in the front-and-back direction; the rolling device is capable of sliding on the underframe in the left-and-right direction; the sheet transporter comprises a carrier, a lifting device and a front-and-back direction sliding device; the carrier is used for carrying the sheets and connected with the lifting device; the lifting device is capable of lifting the carrier so as to adjust the up-and-down positions of the sheets on the carrier; the lifting device is connected with the front-and-back direction sliding device; the rolling device comprises upper and lower two cantilever rollers; the sheets are driven by the sheet transporter to extend between the upper and lower two cantilever rollers; the two cantilever rollers are capable of exerting clamping force on the sheets and rolling the sheets when the rolling device slides in the left-and-right direction.

Owner:泰州市润扬电气有限公司

Panel processing method utilizing left limiting sensor, right limiting senor and clamping head limiting sensor

The invention provides a panel processing method utilizing a left limiting sensor, a right limiting senor and a clamping head limiting sensor. An adopted device comprises an underframe, a left rack, a right rack, a panel conveying device and a rolling device, wherein the left rack is arranged at the left end of the underframe, the right rack is arranged at the right end of the underframe, the panel conveying device and the rolling device are arranged between the left end of the underframe and the right end of the underframe. The panel conveying device can enable carried panels to move on the underframe in the forward and backward direction. The rolling device can slide on the underframe in the left-right direction. The forward and backward direction is perpendicular to the left-right direction in the horizontal plane. The panel conveying device comprises bearing brackets, a lifting device and a front-and-back sliding device. In the processing process, the bearing brackets are used for carrying the panels and are connected with the lifting device. The lifting device can enable the bearing brackets to ascend and descend so that the vertical position of the panels can be adjusted when the panels are carried.

Owner:安徽宇测线缆质检技术有限公司

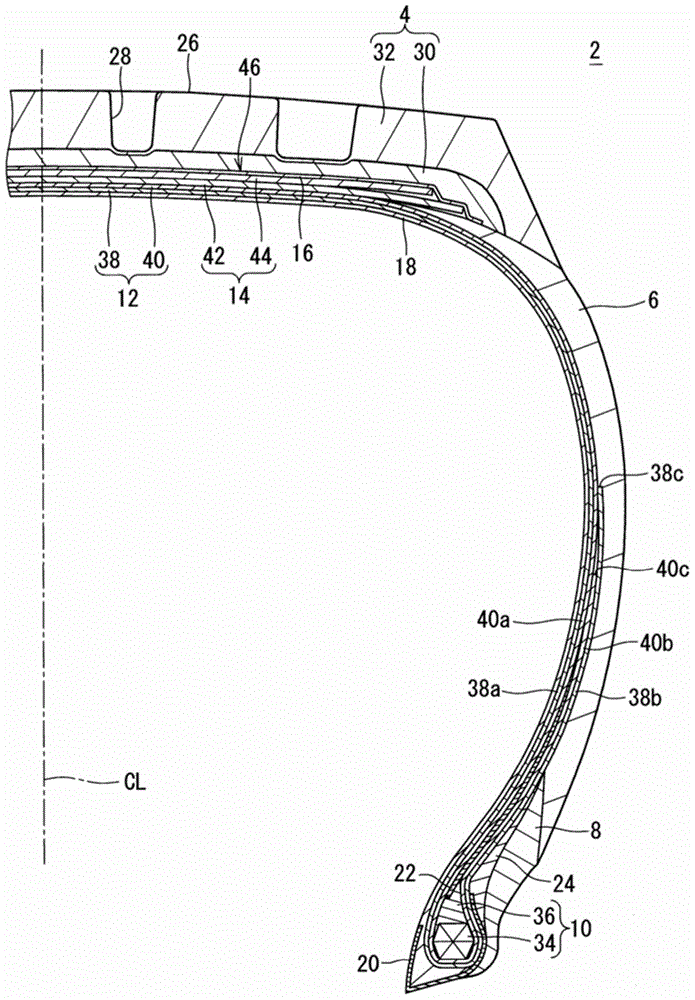

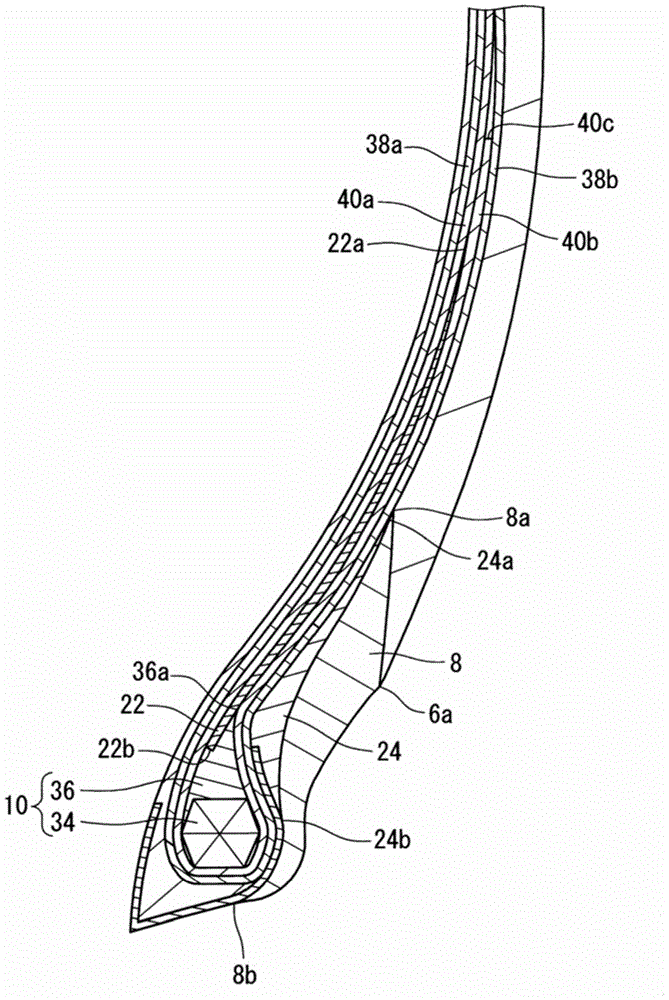

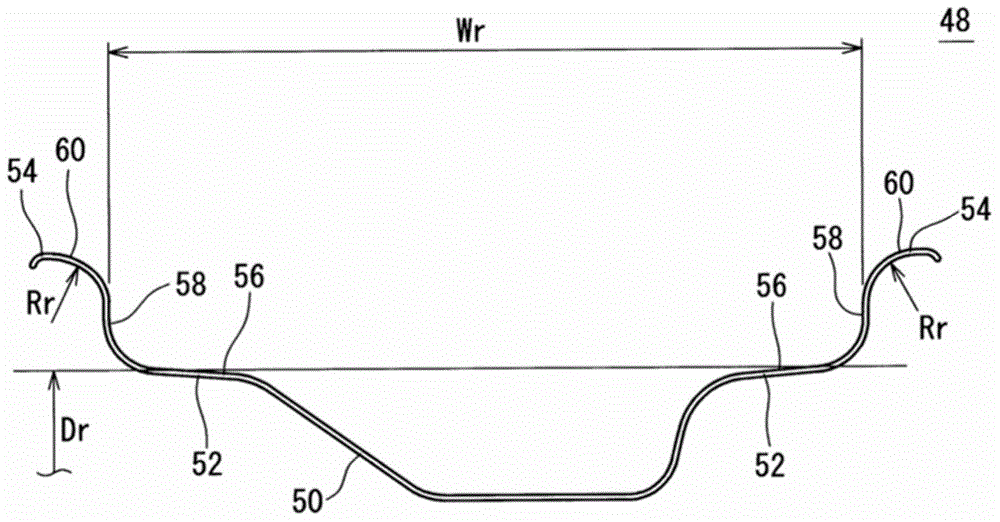

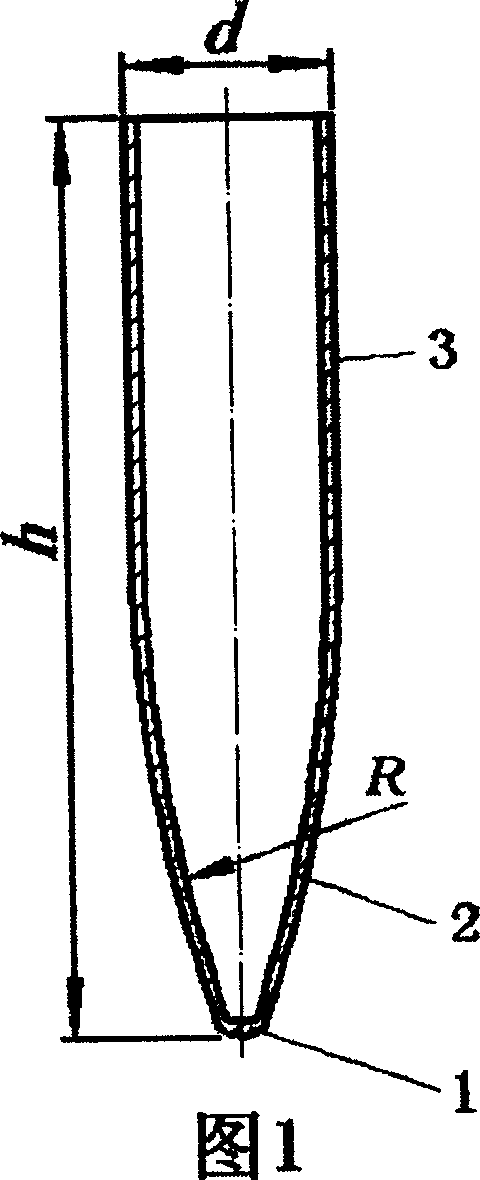

Tire

The invention provides a tire. An apex of a bead has excellent durability. A regular rim (48) equipped with a tire (2) is provided with a rim (54). A buckling peripheral face (60) is formed on the rim (54), is arranged on a radial outer side edge abutted against an apex part (8) and bends with a curvature radius R. A straight line which passes a central point Pr of the curvature radius R and axially extends is set as a first datum line L1. An angle between a straight line which extends via the central point Pr and a front end (36a) of an apex (36) and the first datum line L1 is set as a position angle alpha of the front end (36a) of the apex (36). Thus, when the tire is assembled on the regular rim (48) and is provided with regular internal pressure and loaded with load of 120% of regular load, the position angle alpha is larger than 0 degree and smaller than 90 degrees.

Owner:SUMITOMO RUBBER IND LTD

Left-and-right movement lead screw and front-and-back movement lead screw used board machining method

The invention discloses a left-and-right movement lead screw and front-and-back movement lead screw used board machining method. A device for achieving the board machining method comprises an under frame, a left machine frame and a right machine frame, wherein the left machine frame is arranged at the left end of the under frame, the right machine frame is arranged at the right end of the under frame, and a board conveying device and a rolling device are arranged between the left end and the right end of the under frame. The board conveying device enables a borne board to move on the under frame in the front-and-back direction, the rolling device can slide on the under frame in the left-and-right direction, and the front-and-back direction is the direction perpendicular to the left-and-right direction in the horizontal plane. The board conveying device comprises bearing frames, a lifting device and a front-and-back direction sliding device, when machining is carried out, the bearing frames are used for bearing the board, are connected with the lifting device, and can be lifted through the lifting device, and therefore the up-and-down position of the board can be adjusted when the board is borne.

Owner:嘉善罗星创业投资有限公司

Panel processing method adopting clamping head limiting sensor and capable of embossing lines

The invention discloses a panel processing method adopting a clamping head limiting sensor and capable of embossing lines. A device used in the method comprises an under frame, a left frame and a right frame, wherein the left frame is arranged at the left end of the udder frame; the right frame is arranged at the right end of the under frame; a panel conveying device and a rolling device are arranged between the left end and the right end of the under frame; the panel conveying device can ensure that panels born on the panel conveying device can move in forward and rearward directions on the under frame; the rolling device can slide in the leftward and rightward directions on the under frame; the forward and rearward direction is perpendicular to the leftward and rightward direction in a horizontal plane; the panel conveying device comprises a bearing frame, a lifting device and a forward and rearward direction sliding device; the bearing frame is used for bearing the panels during processing; the bearing frame is connected with the lifting device; the lifting device can lift the bearing frame, thereby being capable to adjust longitudinal positions of the panels when bearing the panels.

Owner:HARBIN UNIV OF SCI & TECH

Method for machining panel through clamping head limiting sensor and back-and-front moving lead screw

The invention discloses a method for machining a panel through a clamping head limiting sensor and a back-and-front moving lead screw. A panel machining device comprises a bottom frame, a left machine frame and a right machine frame, the left machine frame is arranged at the left end of the bottom frame, the right machine frame is arranged at the right end of the bottom frame, a panel conveying device and a rolling device are arranged between the left end of the bottom frame and the right end of the bottom frame, the panel conveying device can enable the borne panel to move on the bottom frame in the front-and-back direction, the rolling device can slide on the bottom frame in the left-and-right direction, and the front-and-back direction is the direction perpendicular to the left-and-right direction in a horizontal plane. The panel conveying device comprises a bearing frame, a lifting device and a front-and-back sliding device, and in the process of machining, the bearing frame is used for bearing the panel and connected with the lifting device, and the lifting device can enable the bearing frame to ascend and descend so that the bearing frame can adjust the vertical position of the panel when bearing the panel.

Owner:JIANGYIN ZHONGQIANG TECH CO LTD

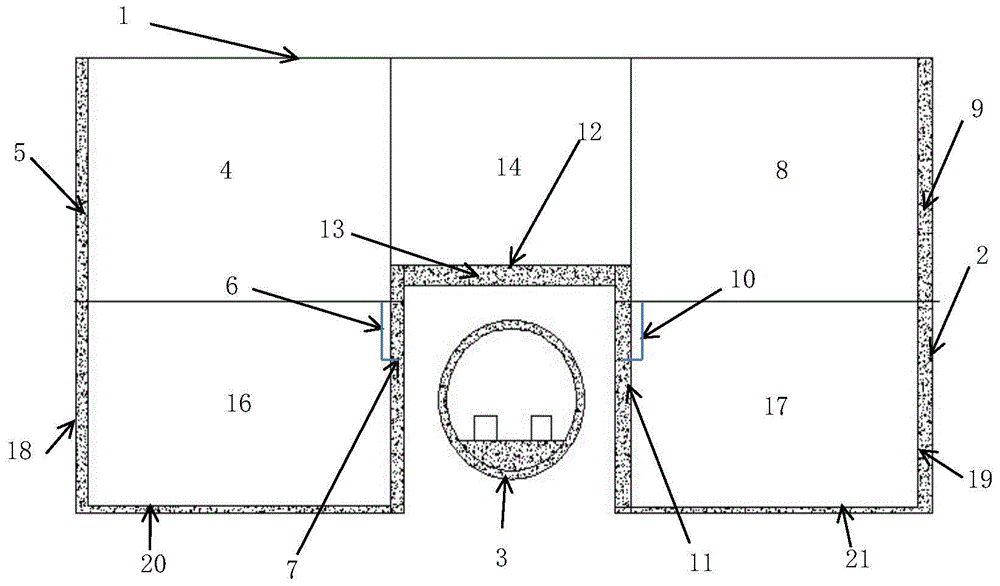

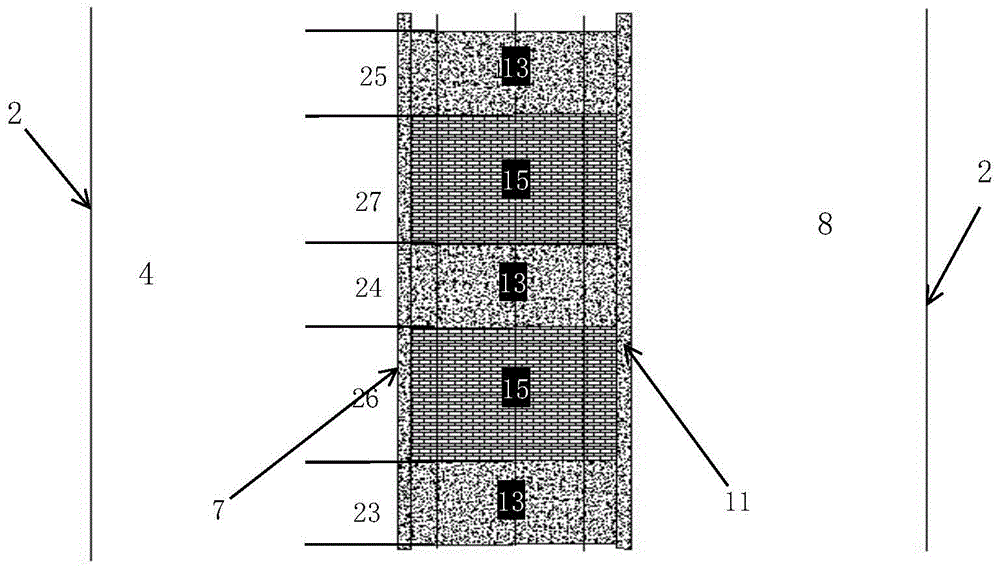

A method for excavating a foundation pit above an operating subway tunnel

The invention relates to an excavation method for a foundation pit above an operation railway tunnel. According to the size of the foundation pit, the outline (1) of the foundation pit is determined, the relative position relation between a foundation pit division region and the railway tunnel is determined, and according to the method, the foundation pit is divided into five regions which include a foundation pit body I (4), a foundation pit body II (8), a foundation pit body III (14), a foundation pit body IV (16) and a foundation pit body V (17). In this way, before the foundation pit is excavated, a concrete protection shell is formed around the tunnel in advance, and influences on the operation tunnel by excavation of the foundation pit are reduced to the maximum degree. The purpose is to overcome the defects and excavate the foundation pit above an operation railway, and the excavation and tunnel protection method for the foundation pit above the operation railway achieves the effect that the operation railway tunnel is closed before the foundation pit above the operation railway tunnel is excavated, so that the operation railway tunnel is not disturbed by excavation of the foundation pit at all.

Owner:CHONGQING UNIV

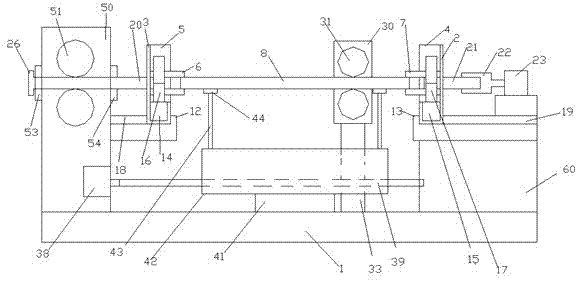

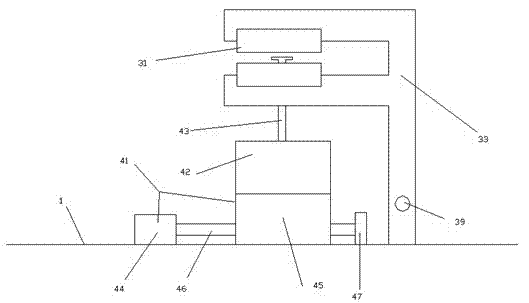

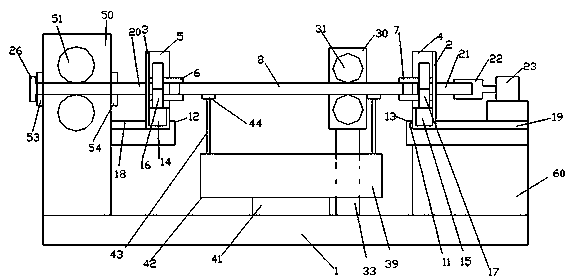

Plate machining method using vacuum chuck and capable of rolling patterns

ActiveCN103786216AGuaranteed straightnessAvoid wrinklesWood compressionEmbossing decorationsMachining processEngineering

The invention relates to a plate machining method and a machining device of the plate machining method. The device used for the machining method comprises a bottom frame, a left rack and a right rack, wherein the left rack is arranged at the left end of the bottom frame, the right rack is arranged at the right end of the bottom frame, a plate conveying device and a rolling device are arranged between the left end and the right end of the bottom frame, the plate conveying device enables borne plates to move in the front and back direction on the bottom frame, the rolling device can slide in the left and right direction of the bottom frame, and the front and back direction is perpendicular to the left and right direction in the horizontal plane; the plate conveying device comprises a bearing frame, a lifting device and a front and back sliding device, in the machining process, the bearing frame is used for bearing the plates and connected with the lifting device, and the lifting device can ascend or descend the bearing frame, so that up and down positions of the plates are adjusted when the plates are borne.

Owner:JIANGSU RIGID BUILDING MATERIALS TECH CO LTD

Panel processing device using screw rod moving leftwards and rightwards and screw rod moving forwards and backwards

The invention relates to a panel processing device using a screw rod moving leftwards and rightwards and a screw rod moving forwards and backwards. The panel processing device comprises an underframe, a panel conveyor and a rolling device. The panel conveyor can enable borne panels to move forwards and backwards on the underframe. The rolling device can slide leftwards and rightwards on the underframe. The panel conveyor comprises a carrier, a lifter and a forward-backward sliding device. The carrier is used for carrying the panels and is connected with the lifter. The lifter can lift the carrier to adjust upper and lower positions of the panels during carrying of the panels, and is connected with the forward-backward sliding device. The rolling device comprises an upper cantilever roller and a lower cantilever roller. The panels can extend into a space between the two cantilever rollers under the drive of the panel conveyor, the cantilever rollers can apply clamp force to the panels, and the rolling device performs roll finishing on the panels when sliding leftwards and rightwards.

Owner:唐山中茂科技有限公司

Plate machining method using vacuum chuck and capable of spraying coating material

The invention relates to a plate machining method using a vacuum chuck and capable of spraying coating material. A device used for the method comprises a bottom frame, a left rack and a right rack, wherein the left rack is arranged at the left end of the bottom frame, the right rack is arranged at the right end of the bottom frame, a plate conveying device and a rolling device are arranged between the left end and the right end of the bottom frame, the plate conveying device enables borne plates to move in the front and back direction on the bottom frame, the rolling device can slide in the left and right direction of the bottom frame, and the front and back direction is perpendicular to the left and right direction in the horizontal plane; the plate conveying device comprises a bearing frame, a lifting device and a front and back sliding device, in the machining process, the bearing frame is used for bearing the plates and connected with the lifting device, and the lifting device can ascend or descend the bearing frame, so that up and down positions of the plates are adjusted when the plates are borne.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Left limiting sensor, right limiting sensor and left-and-right movement lead screw used board machining method

The invention discloses a left limiting sensor, right limiting sensor and left-and-right movement lead screw used board machining method. A device for achieving the board machining method comprises an under frame, a left machine frame and a right machine frame, wherein the left machine frame is arranged at the left end of the under frame, the right machine frame is arranged at the right end of the under frame, and a board conveying device and a rolling device are arranged between the left end and the right end of the under frame. The board conveying device enables a borne board to move on the under frame in the front-and-back direction, the rolling device can slide on the under frame in the left-and-right direction, and the front-and-back direction is the direction perpendicular to the left-and-right direction in the horizontal plane. The board conveying device comprises bearing frames, a lifting device and a front-and-back direction sliding device, when machining is carried out, the bearing frames are used for bearing the board, are connected with the lifting device, and can be lifted through the lifting device, and therefore the up-and-down position of the board can be adjusted when the board is borne.

Owner:安徽宇测线缆质检技术有限公司

Plate machining method using vacuum chuck and left-right moving screw rod of rolling device

ActiveCN103786224AGuaranteed straightnessAvoid wrinklesWood working apparatusMachining processChassis

The invention relates to a plate machining method using a vacuum chuck and a left-right moving screw rod of a rolling device. A device used for the method comprises a bottom frame, a left rack and a right rack, wherein the left rack is arranged at the left end of the bottom frame, the right rack is arranged at the right end of the bottom frame, a plate conveying device and a rolling device are arranged between the left end and the right end of the bottom frame, the plate conveying device enables borne plates to move in the front and back direction on the bottom frame, the rolling device can slide in the left and right direction of the bottom frame, and the front and back direction is perpendicular to the left and right direction in the horizontal plane; the plate conveying device comprises a bearing frame, a lifting device and a front and back sliding device, in the machining process, the bearing frame is used for bearing the plates and connected with the lifting device, and the lifting device can ascend or descend the bearing frame, so that up and down positions of the plates are adjusted when the plates are borne.

Owner:安徽宇测线缆质检技术有限公司

Plate processing device

The invention relates to a plate processing device which comprises a bottom frame, a plate conveying device and a rolling device. Carried plates can move along the front-back direction on the bottom frame under the effect of the plate conveying device, the rolling device can slide along the left-right direction on the bottom frame, the plate conveying device comprises a carrying frame, a lifting device and a front-back direction sliding device, and the carrying frame is used for carrying the plates, is connected with the lifting device and can be lifted by the lifting device, so that the plates can be repositioned in the up-down direction when carried; the lifting device is connected with the front-back direction sliding device; the rolling device comprises an upper cantilever roll and a lower cantilever roll, the plates can be driven by the plate conveying device to extend into a space between the upper cantilever roll and the lower cantilever roll, clamping force can be exerted by the two cantilever rolls on the plates, and the plates can be subjected to rolling processing when the rolling device slides along the left-right direction.

Owner:NANTONG TONGYANG MECHANICAL & ELECTRICAL MFR

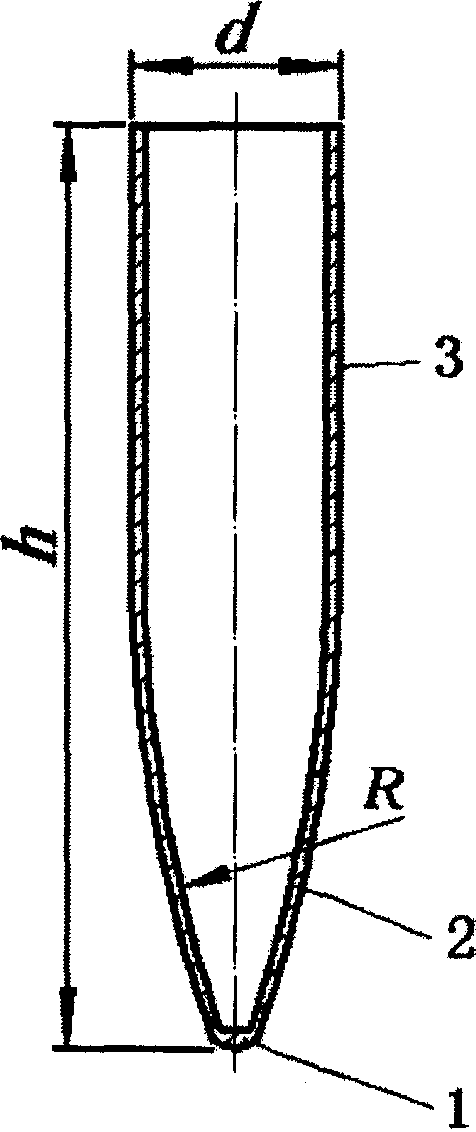

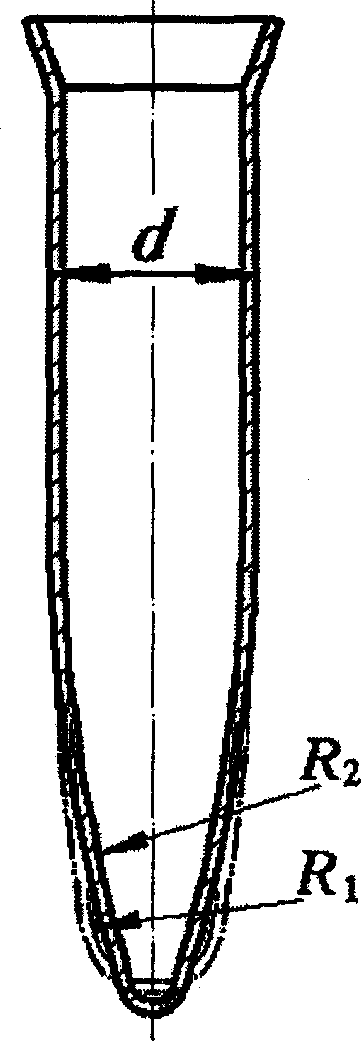

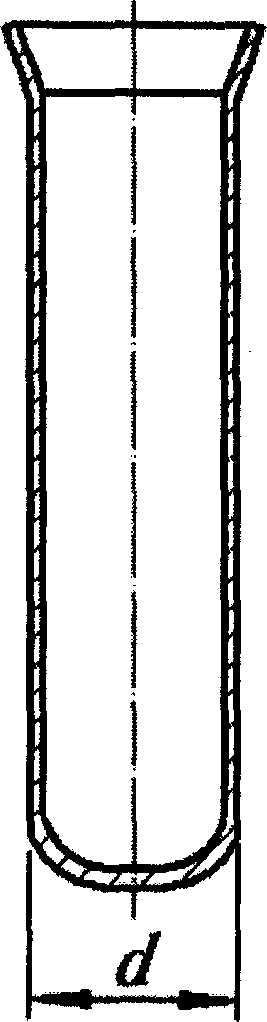

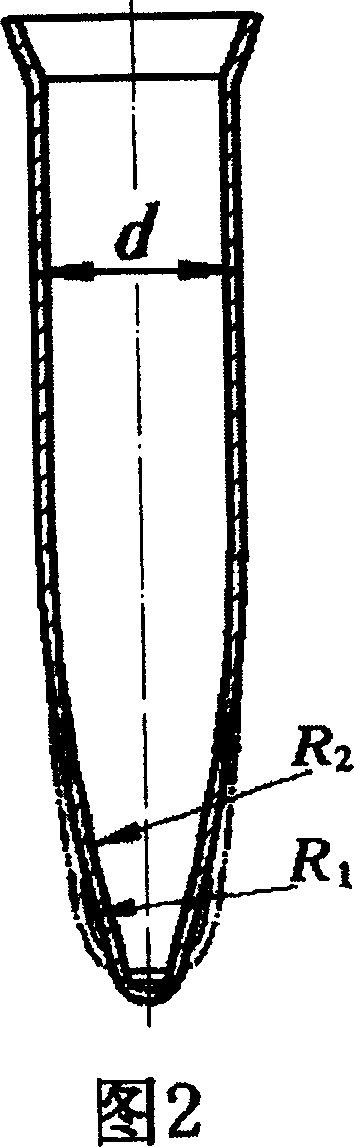

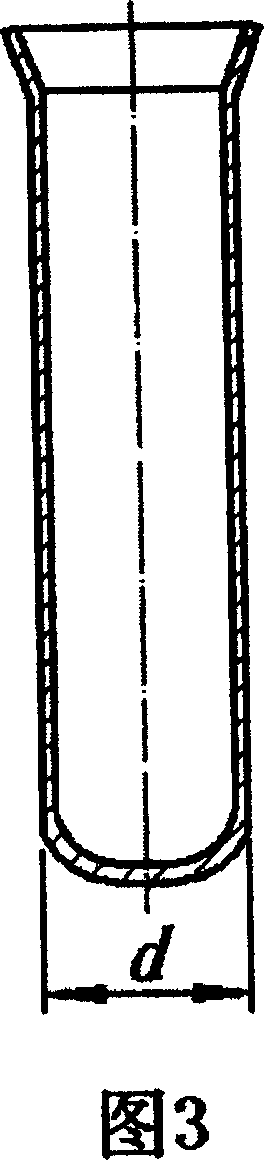

Bullet shell multi-station continuous shaping punching process

This present invention relates to a warhead continuum figuration pressing craft. It solves the vice of anneal in the present process. This process is as follow. Blank and draw the feed to get a columnar workpiece which is thin as parietal and thick as bottom. Then gradually reduce the diameter of the bottom by one or more thin drawing. Respectively shape up the arc cone surface, finally finishing. There is no need of anneal at the mid of this process. Also this invention has the virtues of high efficiency and low cost.

Owner:FUJIAN UNIV OF TECH

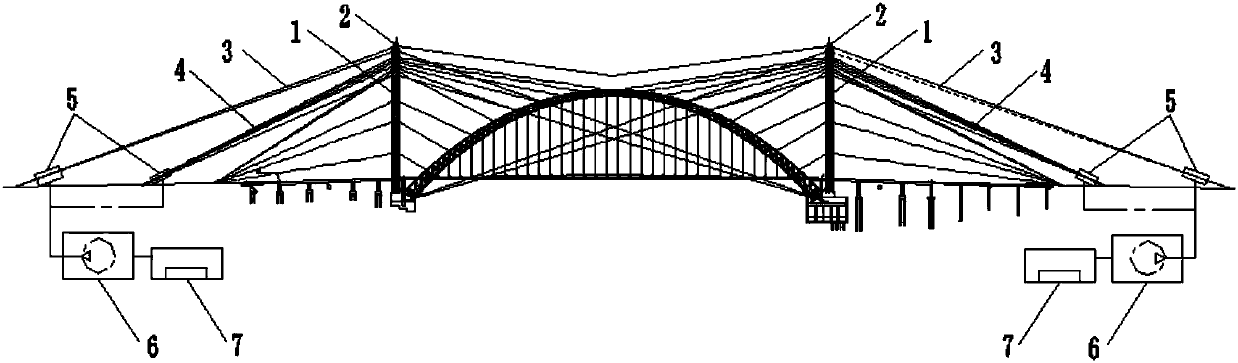

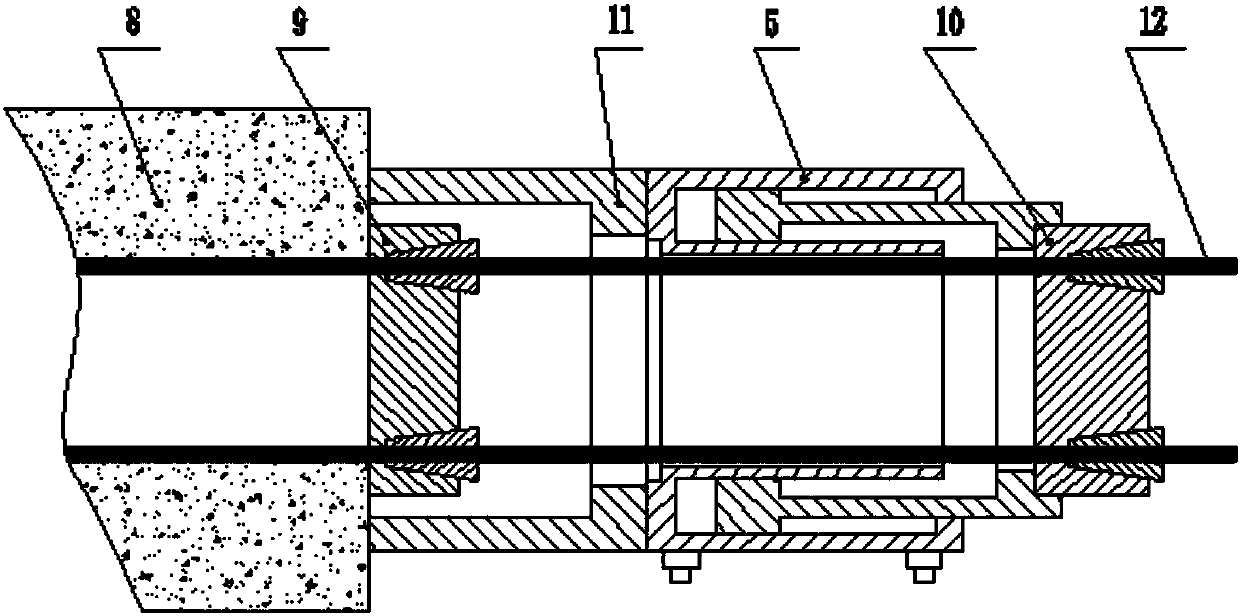

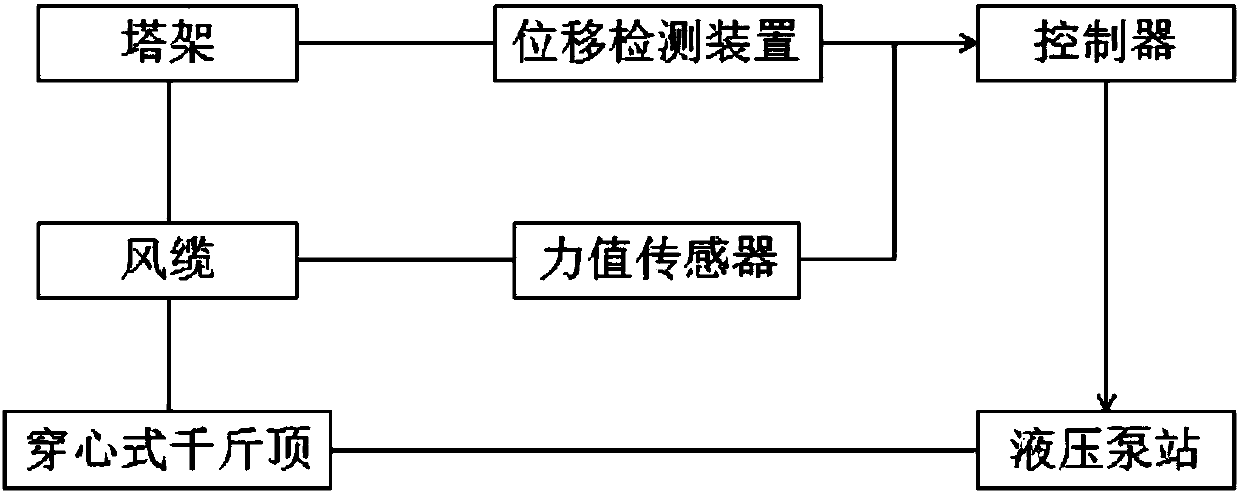

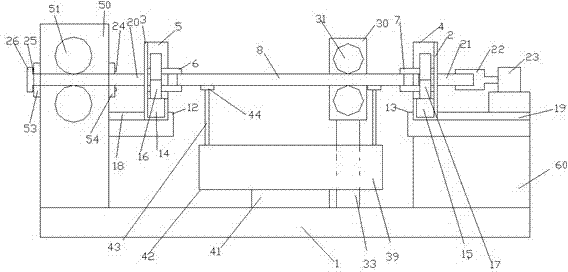

Displacement control system and application method of cable crane tower frame for arch bridge construction

ActiveCN107620260BImprove control effectAvoid repeated deformationBridge erection/assemblyControl systemOptimal control

The invention discloses an arch bridge construction cable tower crane frame displacement control system and a using method. The arch bridge construction cable tower crane frame displacement control system comprises a displacement detection device, a tension device and a controller, the displacement detection device is arranged at the top of a tower frame, the tension device is arranged at the ground anchor end of a wind cable, and the controller controls the magnitude of tension applied to the wind cable by the tension device according to tower frame displacement data fed back by the displacement detection device. When the tower frame is displaced, the tension device can apply the tension to the wind cable, therefore it is ensured that the tower frame is in a perpendicular state or a smalldisplacement deflection state, and since the wind cable can be timely tightened according to the displacement of the tower frame, the wind cable with large rigidity and the large diameter is not needed. The arch bridge construction cable tower crane frame displacement control system can achieve active control of the displacement of the tower frame, optimal control can be achieved according to actual displacement conditions of the tower frame, the safety of the tower frame when the stress is high is ensured, the control effect of the system is good, construction materials are saved, and largedisplacement and repeated deformation of an arch rib are avoided.

Owner:GUANGXI UNIV +1

Left limiting sensor and right limiting sensor used board machining method capable of suppressing grains

The invention discloses a left limiting sensor and right limiting sensor used board machining method capable of suppressing grains. A used device comprises an under frame, a left machine frame and a right machine frame, wherein the left machine frame is arranged at the left end of the under frame, the right machine frame is arranged at the right end of the under frame, and a board conveying device and a rolling device are arranged between the left end and the right end of the under frame. The board conveying device enables a borne board to move on the under frame in the front-and-back direction, the rolling device can slide on the under frame in the left-and-right direction, and the front-and-back direction is the direction perpendicular to the left-and-right direction in the horizontal plane. The board conveying device comprises bearing frames, a lifting device and a front-and-back direction sliding device, when machining is carried out, the bearing frames are used for bearing the board, are connected with the lifting device, and can be lifted through the lifting device, and therefore the up-and-down position of the board can be adjusted when the board is borne.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

Plate machining method using vacuum chuck and left-right moving screw rod of rolling device

ActiveCN103786224BGuaranteed straightnessAvoid wrinklesWood working apparatusEngineeringMachining process

The invention relates to a plate machining method using a vacuum chuck and a left-right moving screw rod of a rolling device. A device used for the method comprises a bottom frame, a left rack and a right rack, wherein the left rack is arranged at the left end of the bottom frame, the right rack is arranged at the right end of the bottom frame, a plate conveying device and a rolling device are arranged between the left end and the right end of the bottom frame, the plate conveying device enables borne plates to move in the front and back direction on the bottom frame, the rolling device can slide in the left and right direction of the bottom frame, and the front and back direction is perpendicular to the left and right direction in the horizontal plane; the plate conveying device comprises a bearing frame, a lifting device and a front and back sliding device, in the machining process, the bearing frame is used for bearing the plates and connected with the lifting device, and the lifting device can ascend or descend the bearing frame, so that up and down positions of the plates are adjusted when the plates are borne.

Owner:安徽宇测线缆质检技术有限公司

Left limiting sensor and right limiting sensor used board machining method capable of suppressing grains

The invention discloses a left limiting sensor and right limiting sensor used board machining method capable of suppressing grains. A used device comprises an under frame, a left machine frame and a right machine frame, wherein the left machine frame is arranged at the left end of the under frame, the right machine frame is arranged at the right end of the under frame, and a board conveying device and a rolling device are arranged between the left end and the right end of the under frame. The board conveying device enables a borne board to move on the under frame in the front-and-back direction, the rolling device can slide on the under frame in the left-and-right direction, and the front-and-back direction is the direction perpendicular to the left-and-right direction in the horizontal plane. The board conveying device comprises bearing frames, a lifting device and a front-and-back direction sliding device, when machining is carried out, the bearing frames are used for bearing the board, are connected with the lifting device, and can be lifted through the lifting device, and therefore the up-and-down position of the board can be adjusted when the board is borne.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

Panel processing method utilizing left limiting sensor, right limiting senor and clamping head limiting sensor

Owner:安徽宇测线缆质检技术有限公司

Sheet material processing method using vacuum suction cup and clamping head limit sensor

InactiveCN103786220BGuaranteed straightnessAvoid wrinklesWood working apparatusEmbedded systemMachining

The invention discloses a vacuum sucking disc and clamping head limiting sensor used board machining method. A device for achieving the board machining method comprises an under frame, a left machine frame and a right machine frame, wherein the left machine frame is arranged at the left end of the under frame, the right machine frame is arranged at the right end of the under frame, and a board conveying device and a rolling device are arranged between the left end and the right end of the under frame. The board conveying device enables a borne board to move on the under frame in the front-and-back direction, the rolling device can slide on the under frame in the left-and-right direction, and the front-and-back direction is the direction perpendicular to the left-and-right direction in the horizontal plane. The board conveying device comprises bearing frames, a lifting device and a front-and-back direction sliding device, when machining is carried out, the bearing frames are used for bearing the board, are connected with the lifting device, and can be lifted through the lifting device, and therefore the up-and-down position of the board can be adjusted when the board is borne.

Owner:海安江理工技术转移中心有限公司

Left limiting sensor and right limiting sensor used method for machining board capable of being sprayed with coating materials

ActiveCN103786218BGuaranteed straightnessAvoid wrinklesWood working apparatusEngineeringCoating materials

The invention discloses a left limiting sensor and right limiting sensor used method for machining a board capable of being sprayed with coating materials. A device for achieving the method comprises an under frame, a left machine frame and a right machine frame, wherein the left machine frame is arranged at the left end of the under frame, the right machine frame is arranged at the right end of the under frame, and a board conveying device and a rolling device are arranged between the left end and the right end of the under frame. The board conveying device enables a borne board to move on the under frame in the front-and-back direction, the rolling device can slide on the under frame in the left-and-right direction, and the front-and-back direction is the direction perpendicular to the left-and-right direction in the horizontal plane. The board conveying device comprises bearing frames, a lifting device and a front-and-back direction sliding device, when machining is carried out, the bearing frames are used for bearing the board, are connected with the lifting device, and can be lifted through the lifting device, and therefore the up-and-down position of the board can be adjusted when the board is borne.

Owner:安徽宇测线缆质检技术有限公司

Plate machining method capable of rolling patterns and spraying coating material

InactiveCN103786217AGuaranteed straightnessAvoid wrinklesWood working apparatusSpray coatingEngineering

The invention relates to a plating machining method capable of rolling patterns and spraying coating material. A device used for the method comprises a bottom frame, a left rack and a right rack, wherein the left rack is arranged at the left end of the bottom frame, the right rack is arranged at the right end of the bottom frame, a plate conveying device and a rolling device are arranged between the left end and the right end of the bottom frame, the plate conveying device enables borne plates to move in the front and back direction on the bottom frame, the rolling device can slide in the left and right direction of the bottom frame, and the front and back direction is perpendicular to the left and right direction in the horizontal plane; the plate conveying device comprises a bearing frame, a lifting device and a front and back sliding device, in the machining process, the bearing frame is used for bearing the plates and connected with the lifting device, and the lifting device can ascend or descend the bearing frame, so that up and down positions of the plates are adjusted when the plates are borne.

Owner:JIANGYIN ZHONGQIANG TECH CO LTD

Sheet metal processing method that can spray coating materials by moving the lead screw left and right

ActiveCN103786223BGuaranteed straightnessAvoid wrinklesWood working apparatusEngineeringCoating materials

The invention discloses a left-and-right movement lead screw used method for machining a board capable of being sprayed with coating materials. A device for achieving the method comprises an under frame, a left machine frame and a right machine frame, wherein the left machine frame is arranged at the left end of the under frame, the right machine frame is arranged at the right end of the under frame, and a board conveying device and a rolling device are arranged between the left end and the right end of the under frame. The board conveying device enables a borne board to move on the under frame in the front-and-back direction, the rolling device can slide on the under frame in the left-and-right direction, and the front-and-back direction is the direction perpendicular to the left-and-right direction in the horizontal plane. The board conveying device comprises bearing frames, a lifting device and a front-and-back direction sliding device, when machining is carried out, the bearing frames are used for bearing the board, are connected with the lifting device, and can be lifted through the lifting device, and therefore the up-and-down position of the board can be adjusted when the board is borne.

Owner:HAIAN HUADA ALUMINUM SECTION

Bullet shell multi-station continuous shaping punching process

This present invention relates to a warhead continuum figuration pressing craft. It solves the vice of anneal in the present process. This process is as follow. Blank and draw the feed to get a columnar workpiece which is thin as parietal and thick as bottom. Then gradually reduce the diameter of the bottom by one or more thin drawing. Respectively shape up the arc cone surface, finally finishing. There is no need of anneal at the mid of this process. Also this invention has the virtues of high efficiency and low cost.

Owner:FUJIAN UNIV OF TECH

A plate processing device capable of avoiding wrinkles on the surface of the plate

The invention relates to a plate processing device. The plate processing device comprises a bottom rack, a plate conveying device and a rolling device, wherein plates on the plate conveying device can move on the bottom rack along the front-back direction with the aid of the plate conveying device; the rolling device can slide on the bottom rack along the left-right direction; the plate conveying device comprises a bearing rack, a lifting device and a front-back direction sliding device; the bearing rack is used for bearing the plates and is connected with the lifting device; the bearing rack can ascend or descend with the aid of the lifting device, so that the up-down positions of the plates can be adjusted when the plates are placed on the bearing rack; the lifting device is connected with the front-back direction sliding device; the rolling device comprises an upper cantilever roll and a lower cantilever roll; the plates can be driven by the plate conveying device to extend in space between the upper cantilever roll and the lower cantilever roll; the two cantilever rolls can apply a clamping force on the plates; and the plates can be subjected to rolling processing when the rolling device slides along the left-right direction.

Owner:七彩人生集团有限公司

Sheet machining device and working method thereof

The invention relates to a sheet machining device and a working method thereof. The sheet machining device comprises a bottom frame, a sheet conveying device and a rolling device, wherein the sheet conveying device can drive a carried sheet to move back and forth on the bottom frame; the rolling device can slide on the bottom frame in the left-right direction; the sheet conveying device comprises a carrying frame, a lifting device and a forward-backward sliding device; the carrying frame is used for carrying the sheet and is connected with the lifting device; the lifting device can lift the carrying frame so as to adjust the vertical position of the sheet during carrying of the sheet and is connected with the forward-backward sliding device; the rolling device comprises upper and lower cantilever rolls; the sheet can extend into the space between the upper and lower cantilever rolls under the driving of the sheet conveying device; the two cantilever rolls can apply clamping force to the sheet and can be used for rolling the sheet when the rolling device slides along the left-right direction.

Owner:封开县威利邦木业有限公司

Sheet material processing method using clamping head limit sensor and capable of pressing texture

The invention discloses a panel processing method adopting a clamping head limiting sensor and capable of embossing lines. A device used in the method comprises an under frame, a left frame and a right frame, wherein the left frame is arranged at the left end of the udder frame; the right frame is arranged at the right end of the under frame; a panel conveying device and a rolling device are arranged between the left end and the right end of the under frame; the panel conveying device can ensure that panels born on the panel conveying device can move in forward and rearward directions on the under frame; the rolling device can slide in the leftward and rightward directions on the under frame; the forward and rearward direction is perpendicular to the leftward and rightward direction in a horizontal plane; the panel conveying device comprises a bearing frame, a lifting device and a forward and rearward direction sliding device; the bearing frame is used for bearing the panels during processing; the bearing frame is connected with the lifting device; the lifting device can lift the bearing frame, thereby being capable to adjust longitudinal positions of the panels when bearing the panels.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com