Dental implants and methods for extending service life

a technology for dental implants and abutments, applied in the field of dental implants, can solve the problems of inability to attach a new crown or abutment, inability to prevent rotation, and relatively soft titanium metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The present invention is concerned with the problem of rotation of a crown, or an abutment and crown, relative to a dental implant to which the abutment and crown are attached. In many applications, the abutment is omitted and a crown attaches directly to the implant. In every instance, the inherent problem of relative rotation is substantially similar. Accordingly, any description that includes an abutment, or any description that omits use of an abutment, is also applicable to the other construction.

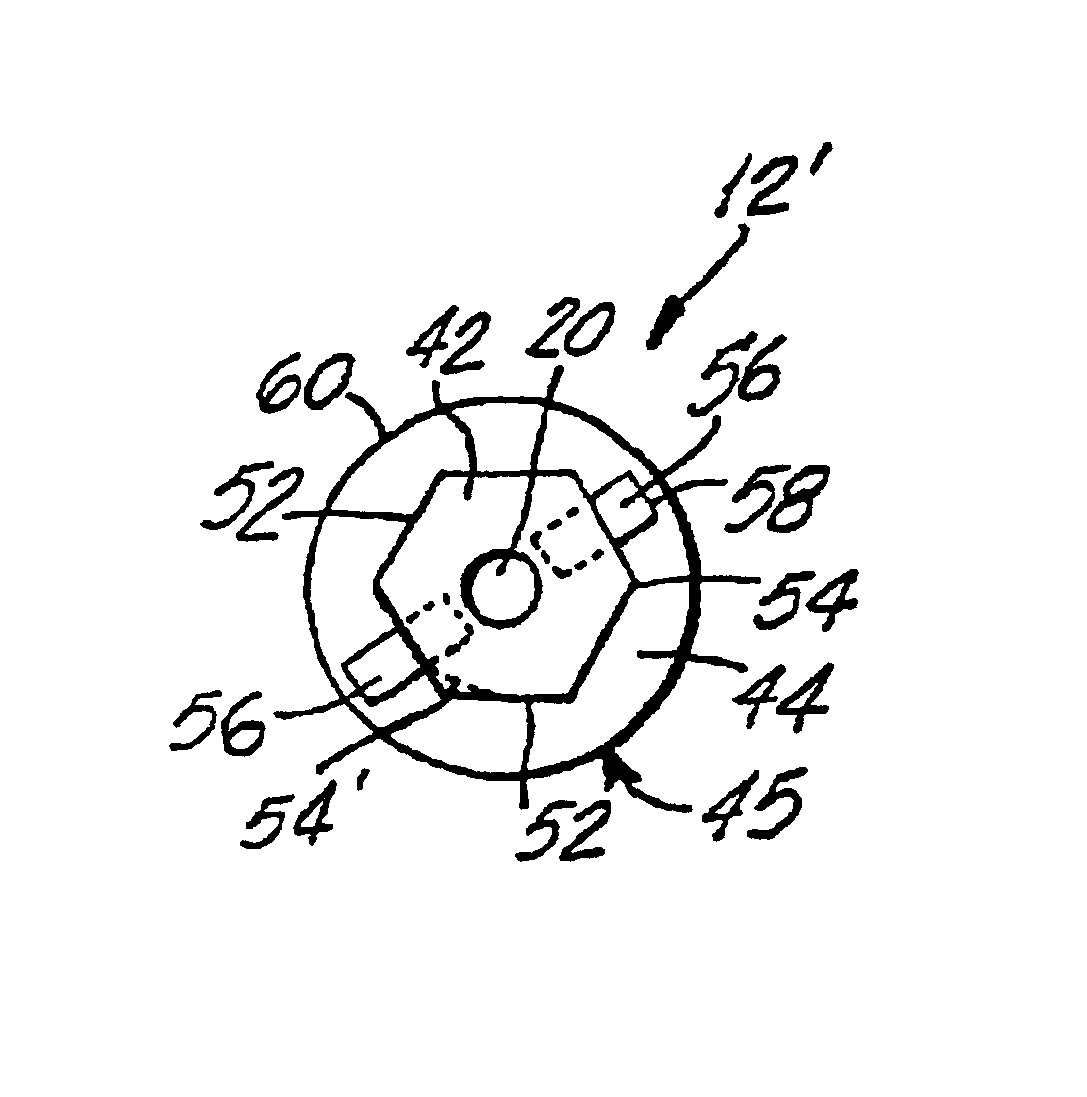

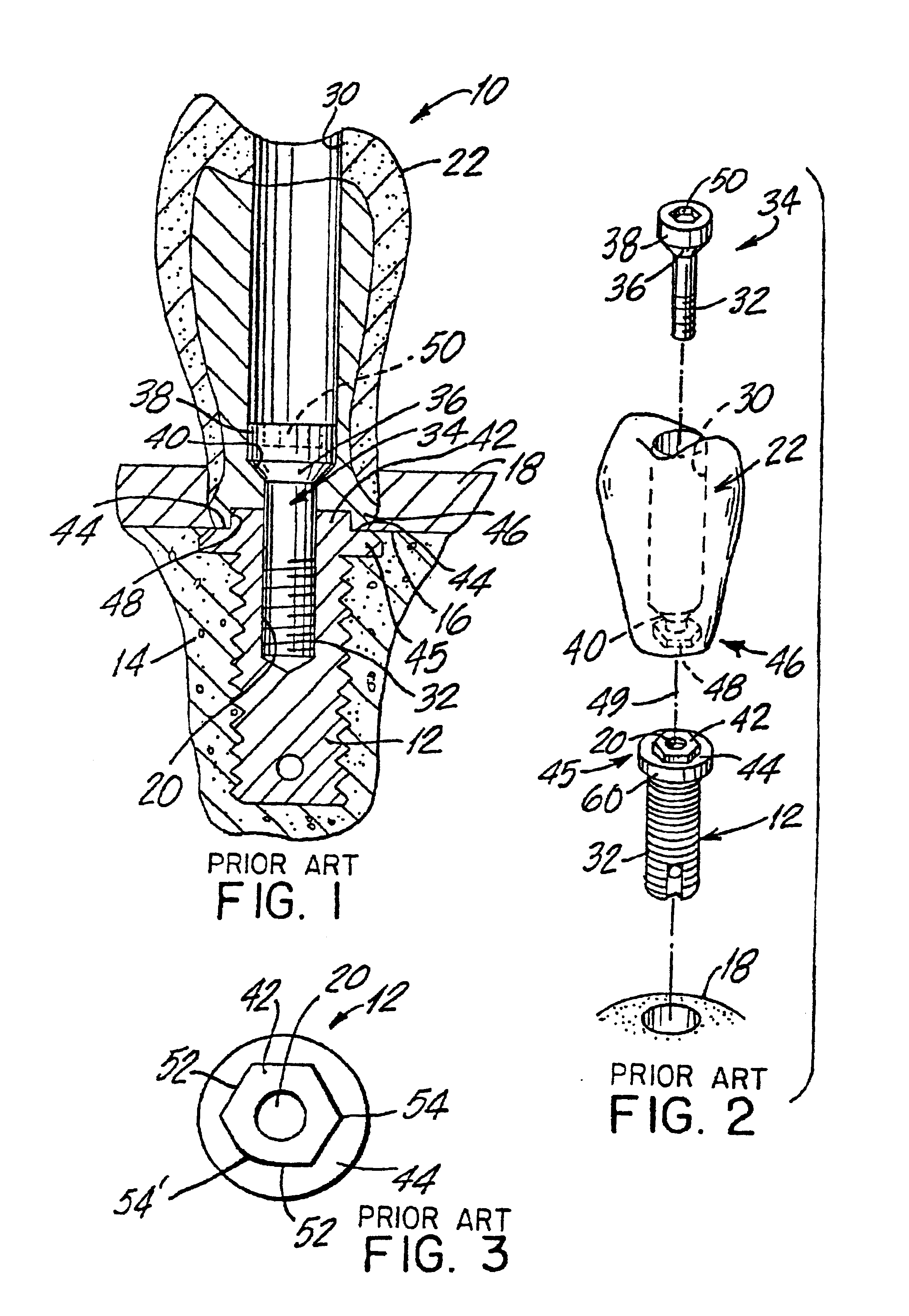

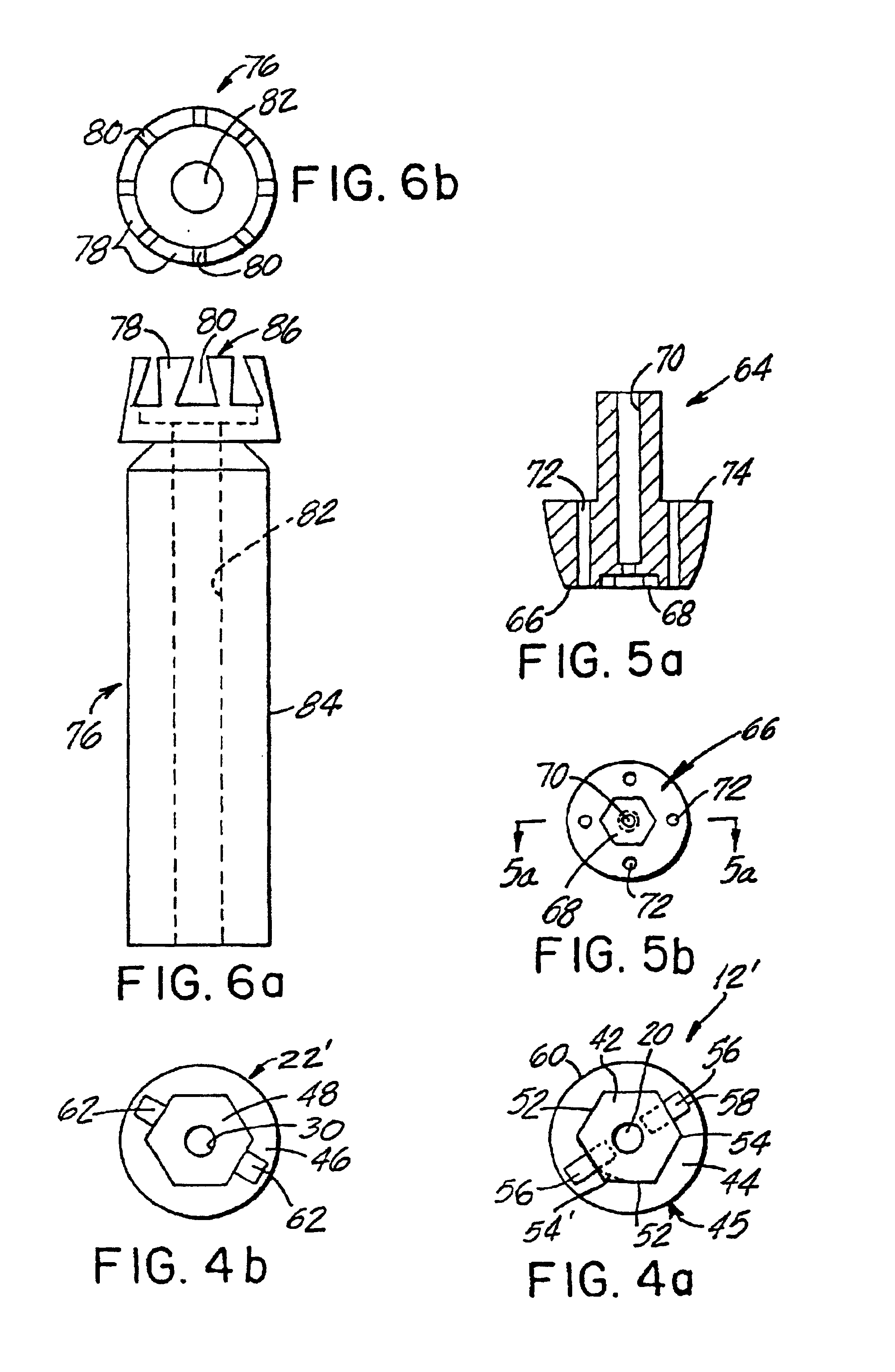

[0041]In FIGS. 1-3, a dental prosthesis 10 of the prior art includes an implant 12 embedded in the spongiosa 14 of the jaw bone. After a healing period of several months, the implant 12 has become part of the bony structure by the known process of osseointegration. The implant 12 protrudes through the cortex 16 of the jaw bone, and the gum tissue 18 conceals the proximal end of the implant 12. A tapped hole 20 opens at the proximal end and is accessible between the parted gum tis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com