Smoke generating apparatus

a technology of generating apparatus and smoke, which is applied in the direction of lighting and heating apparatus, combustion air/fuel air treatment, machines/engines, etc., can solve the problems of heating element not working as intended, safety concerns, and heat build-up so as to increase the surface area of smoke generating fluid exposur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

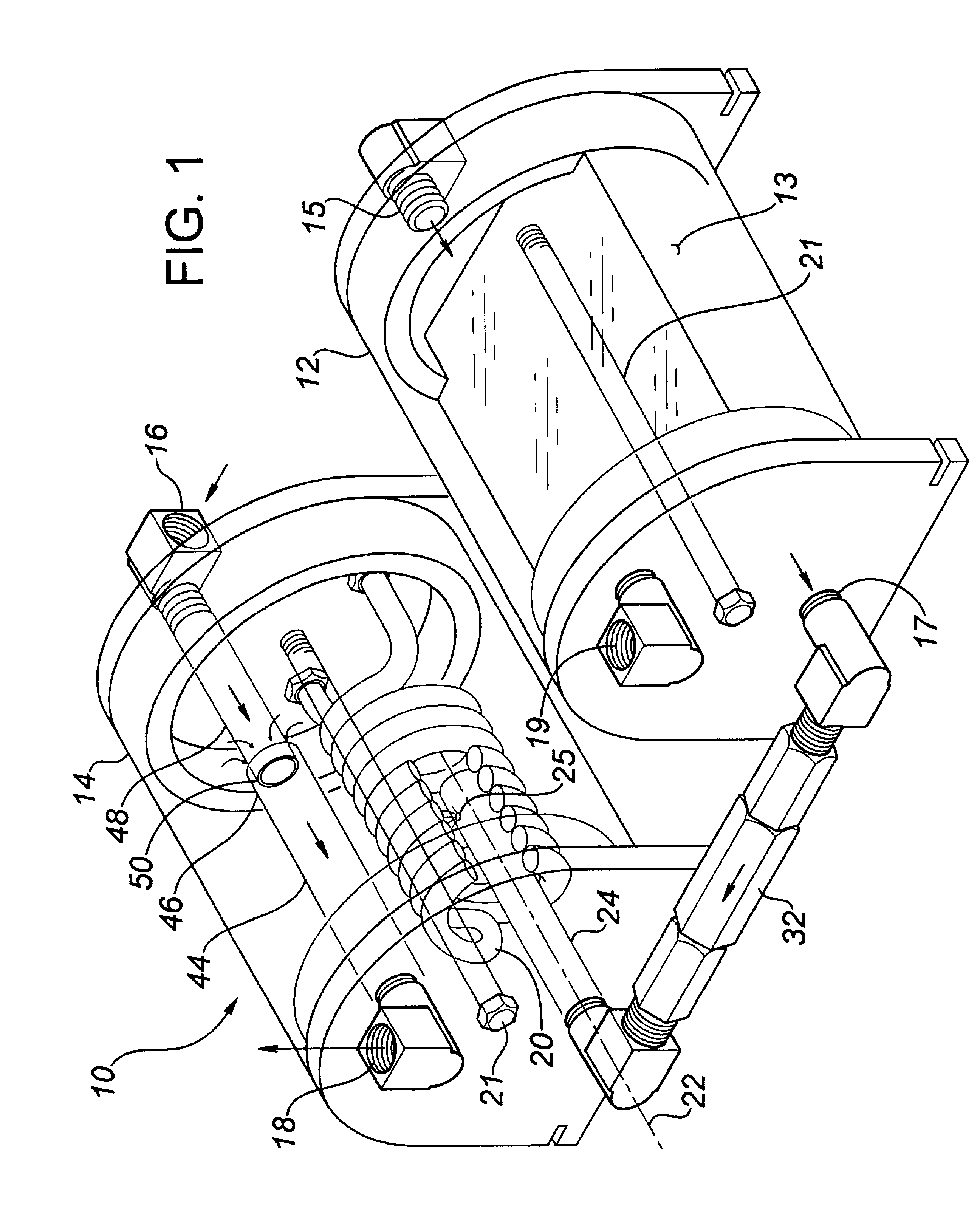

The preferred embodiment, a smoke generating apparatus generally identified by reference numeral 10, will now be described with reference to FIGS. 1 and 2.

Referring to FIG. 1, smoke generating apparatus 10 includes a reservoir 12 for smoke generating fluid 13 and a separate combustion chamber 14. Reservoir 12 has an air flow inlet 15 and a smoke generating fluid flow outlet 17. Reservoir 12 also has a port 19 to enable the addition of smoke generating fluid 13. Combustion chamber 14 has an air flow inlet 16 and an air flow outlet 18. The particular construction of reservoir 12 and combustion chamber 14 illustrated use clamping rods 21 to hold the components together. An insulated helical heating element 20 is disposed in combustion chamber 14. Helical heating element 20 has a central axis 22. A smoke generating fluid injection tube 24 is positioned along central axis 22 of helical heating element 20. Injection tube 24 has at least one upwardly angled injection port 25. Referring to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com