Wick-based liquid emanation system with child-resistant overcap

a liquid emanation system and wick technology, applied in the field of wick-based liquid emanation systems, can solve the problems of affecting the safety of children, the contents of the system being prematurely lost, and the potential that children will come into contact with the liquid contents of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

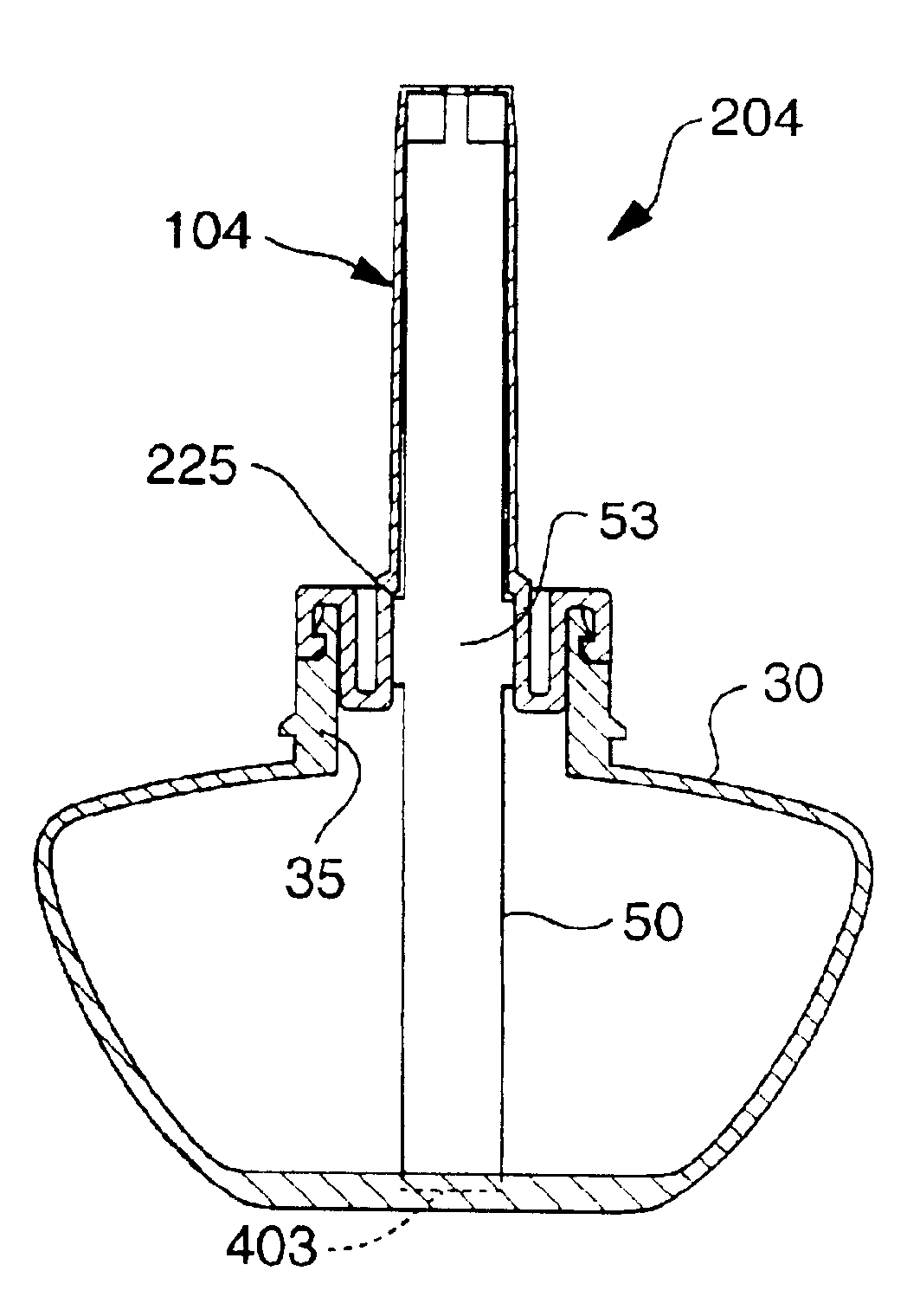

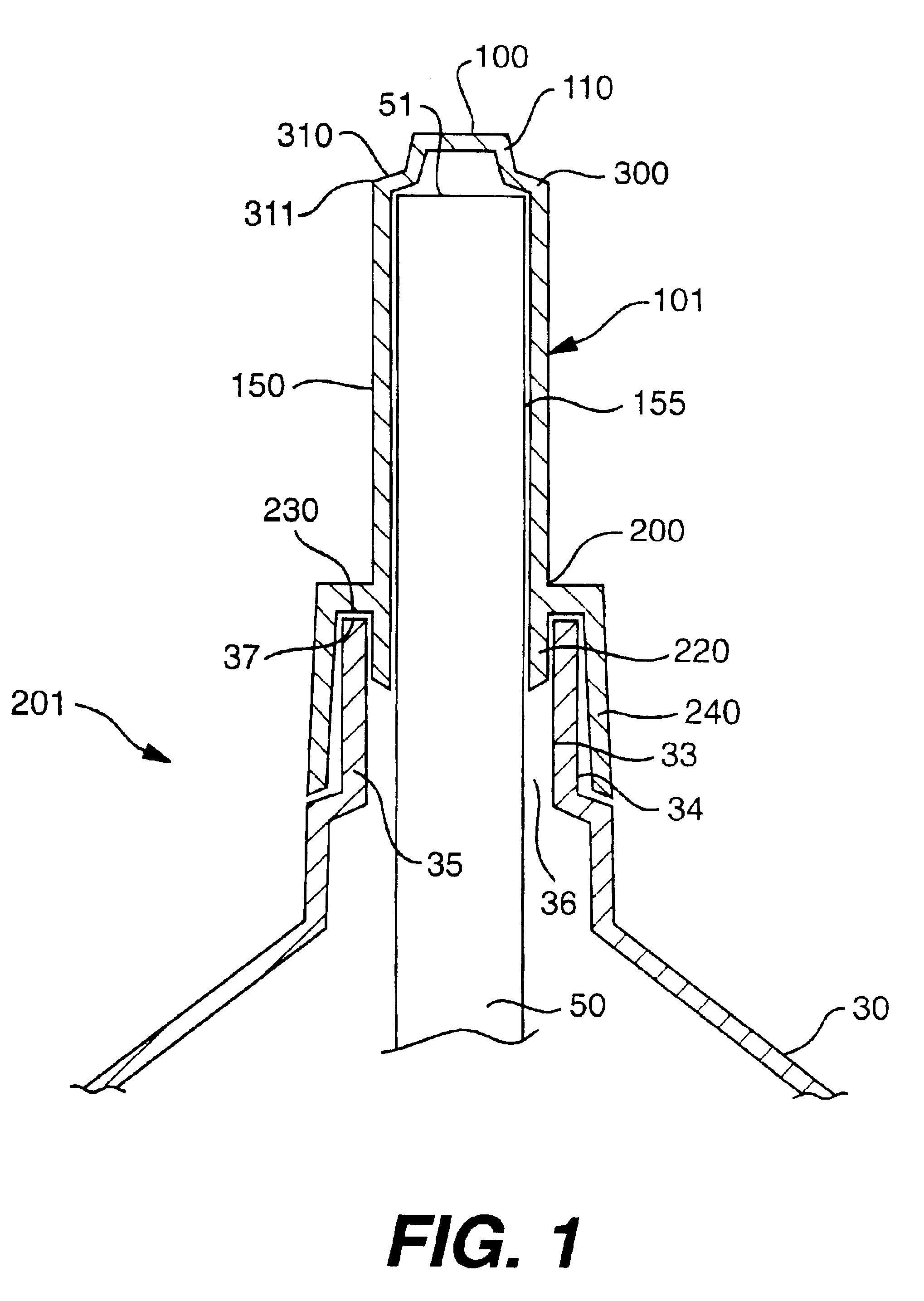

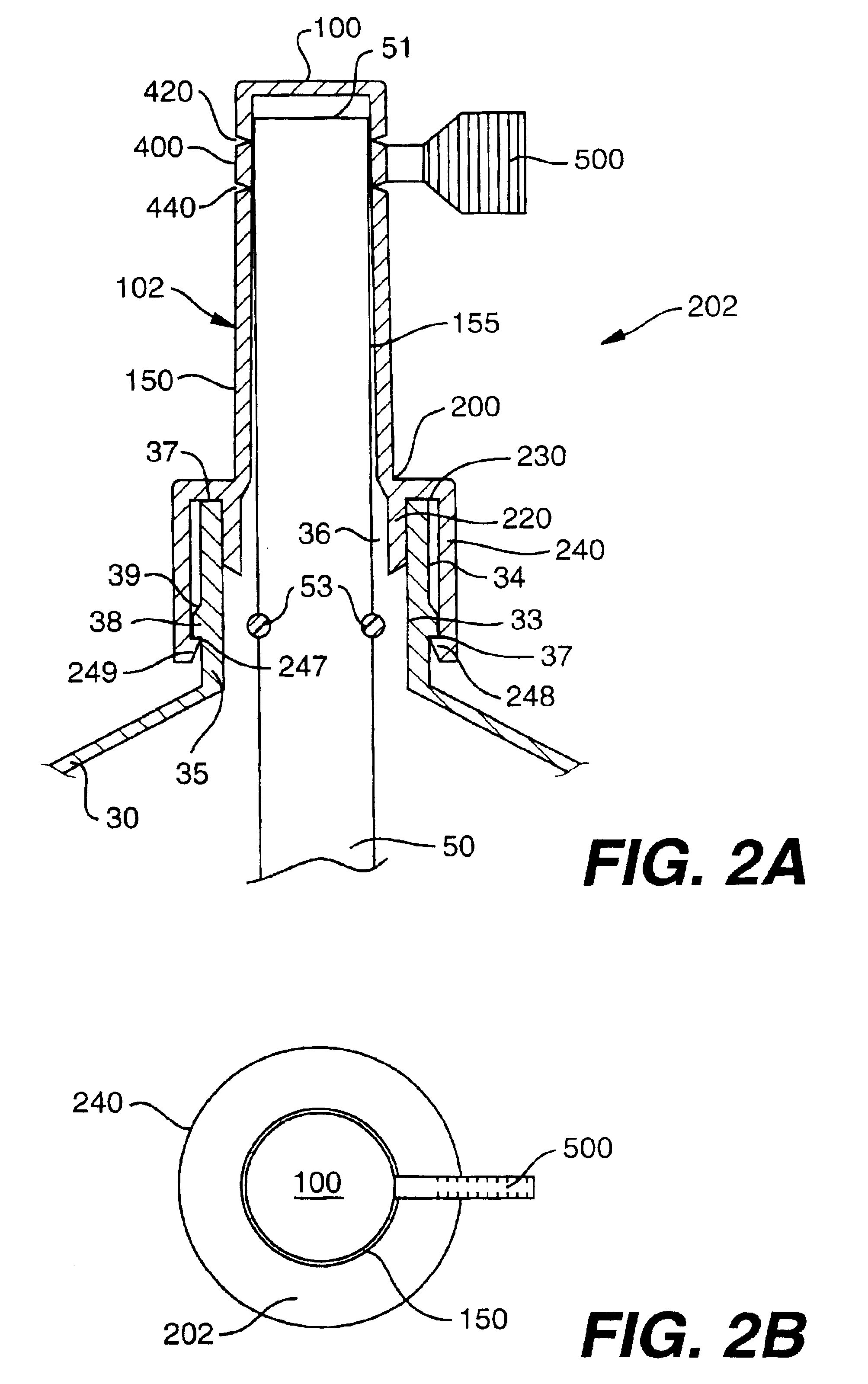

FIG. 1 shows a partial cross-sectional view, in elevation, of a first preferred embodiment of the wick-based liquid emanation system 201 of the present invention. Liquid emanation system 201 includes a container 30 for containing a liquid (not shown) to be dispersed, a wick 50 partially disposed in container 30 and an overcap 101 secured to container 30. These features will be discussed in more detail below.

One end (not shown) of the wick 50 is partially submerged in the liquid to be emanated. The shape of the container 30 is not an essential feature of the invention. Therefore, the portion of the container 30 containing the liquid is not shown in detail in the drawing. The other end of wick 50 extends out through an opening 36 in the container 30. In this embodiment, the container 30 has a neck 35 through which the opening 36 is disposed.

In this embodiment, the overcap 101 is shown having a generally circular cross section, and is secured to the neck 35 of the container 30, as will...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com