Luer-receiving medical valve

a medical valve and receiver technology, applied in the field of receiving medical valves, can solve the problems of not working system, not being able to detect the damage of the needlestick, not being able to detect the damage of the accessory cannula, etc., and achieve the effects of reducing the risk of needlestick injury, minimal cost, and easy wiped with antisepti

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

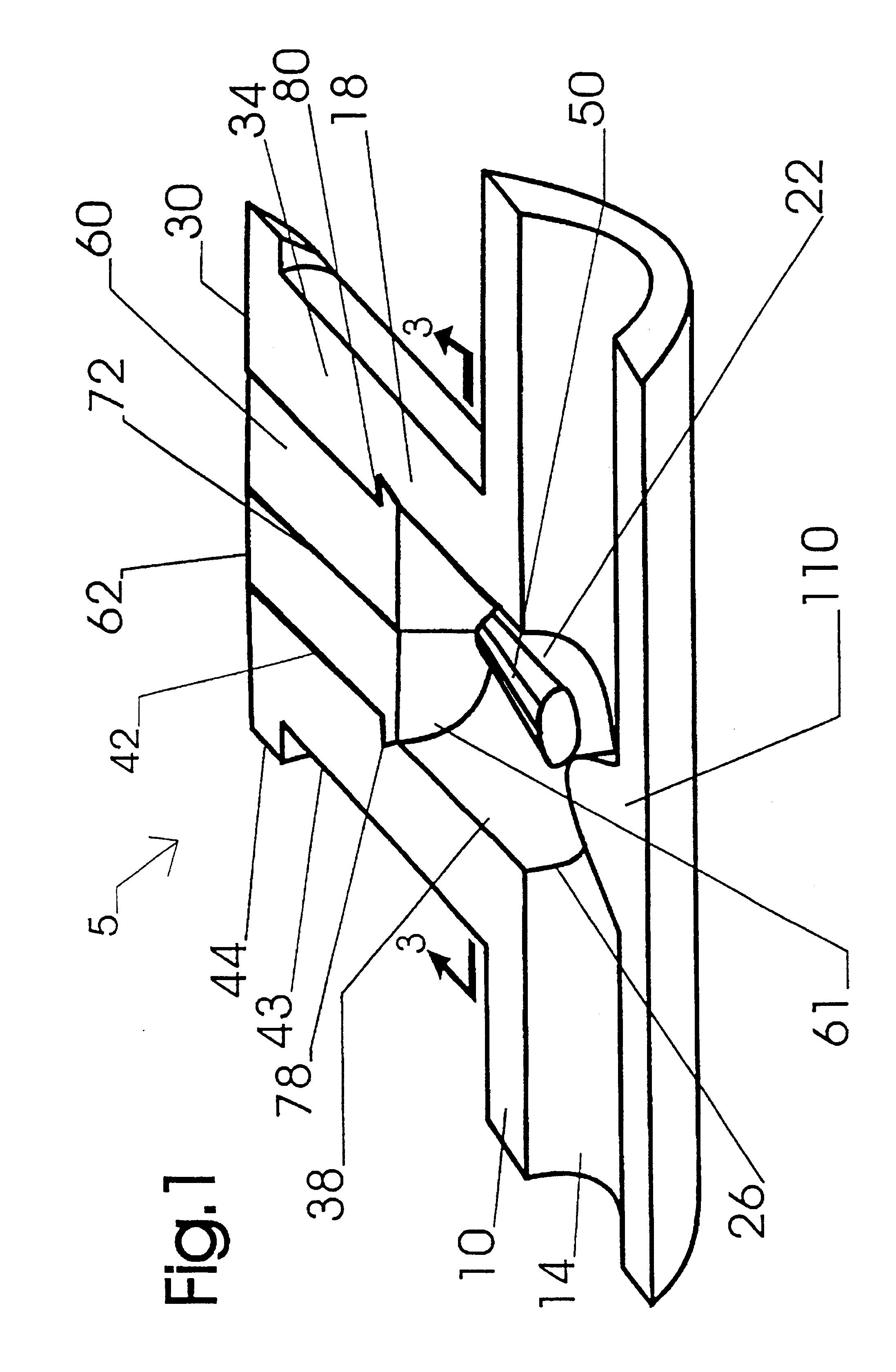

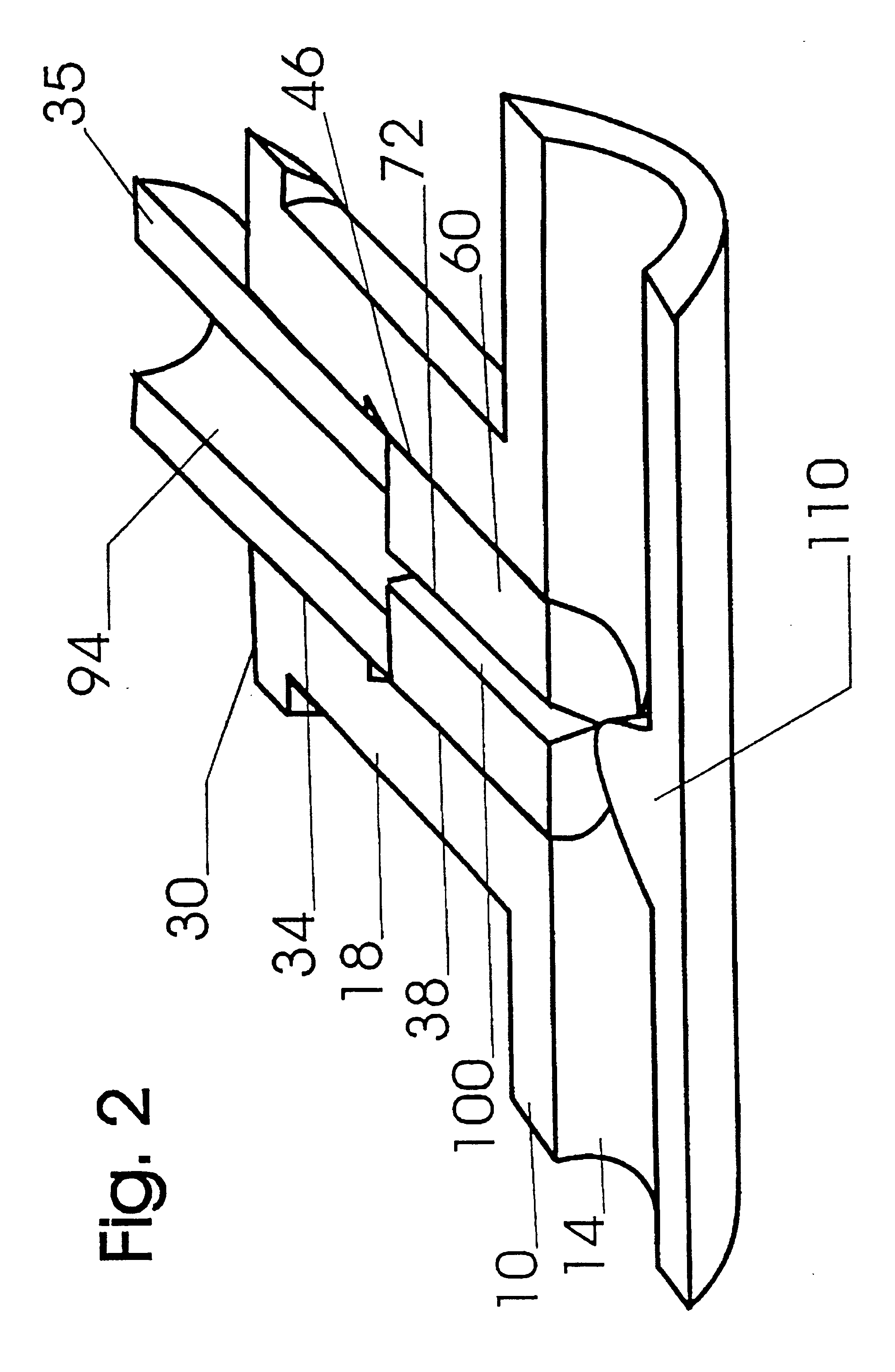

In one preferred embodiment, the luer tapered cannula receiving valve 5 (FIGS. 1-6) includes a main conduit housing 10 having a main bore 14 and a secondary branch or cylinder 18 having a secondary bore 22. The cylinder 18 includes a distal end 26 adjacent the main bore 10 and a proximal end 30. The cylinder 18 further includes a cylindrical proximal bore portion 34 sized to sealingly receive a conventional tapered luer male cannula 35 (as shown in FIG. 2) and distal bore portion 38. The proximal bore portion 34 is defined by inner cylindrical walls 42 and outer walls 43 and includes outer thread receiving post 44 adjacent the proximal end 30 (although complete outer threads may be provided). A distal bore portion 38 is defined by distal wall 46 having opposing projecting members 50 which effectively narrow the transverse width of the distal bore portion 38 along a longitudinal plane through the opposing projecting members 50 (as best shown in FIG. 3). A cylindrical elastomeric sept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com