Swept turbomachinery blade

a turbomachinery and blade technology, applied in the field of turbomachinery blades, can solve the problems of pressure waves which extend along the span and degrade and achieve the effect of optimizing the efficiency of the engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

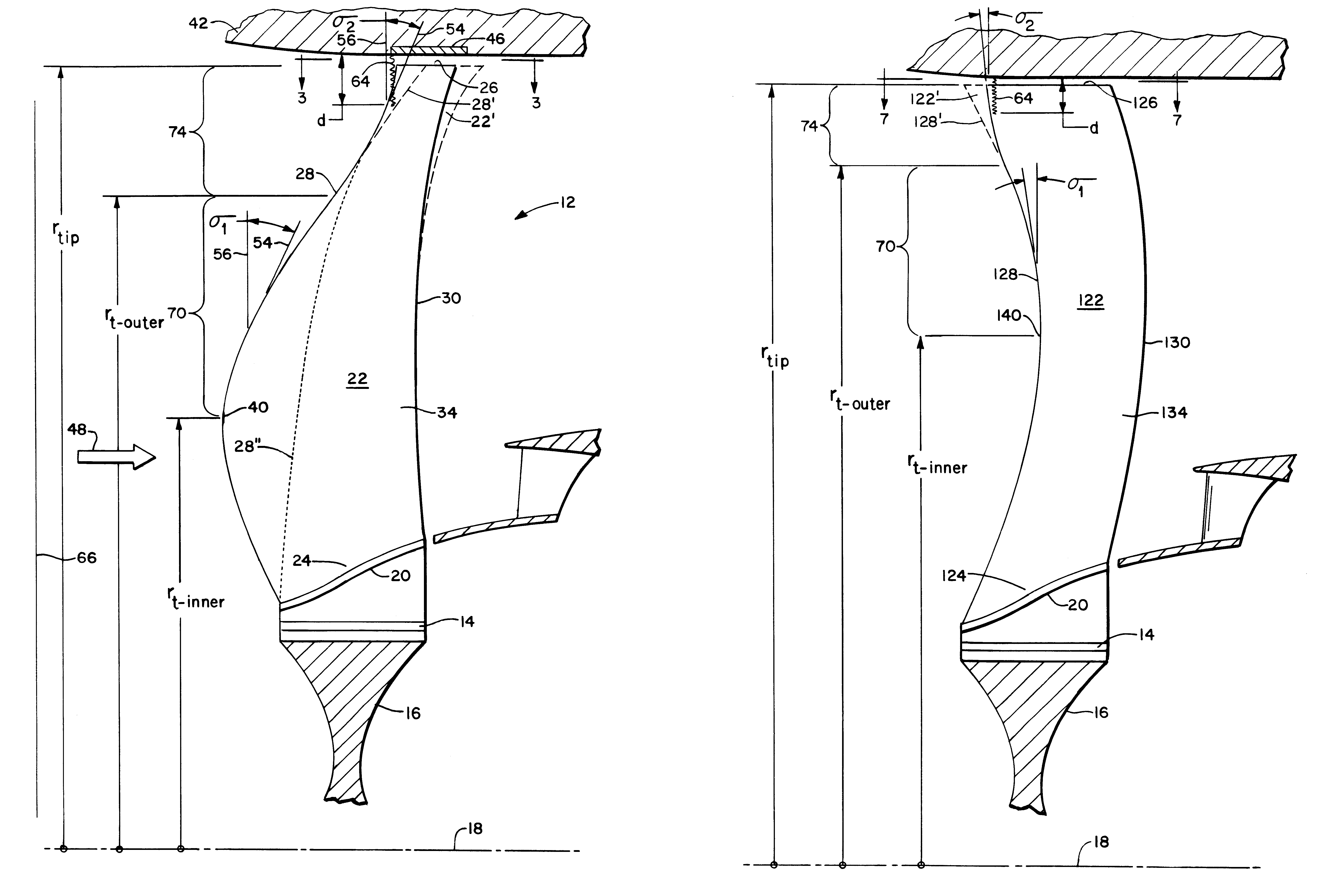

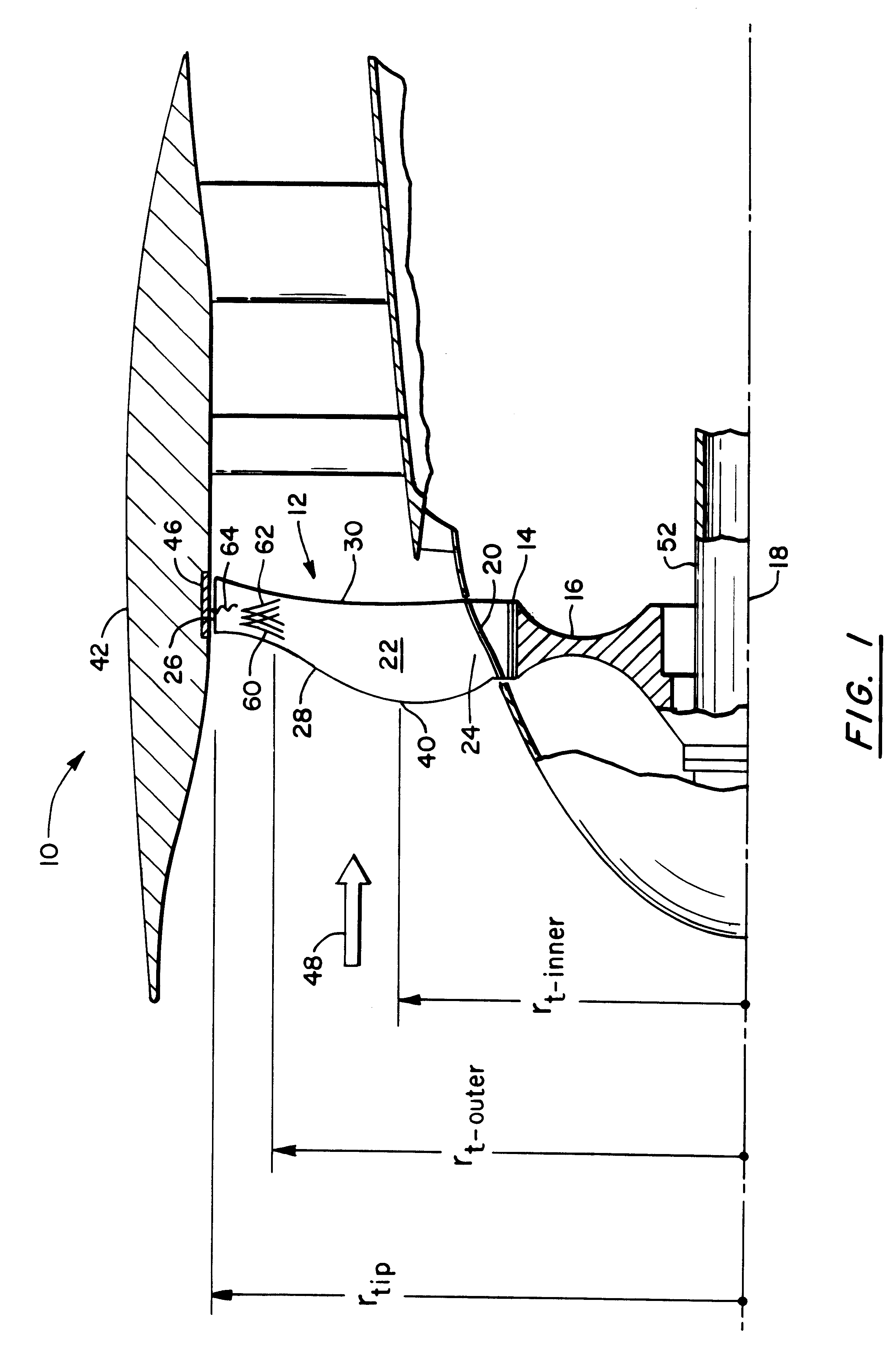

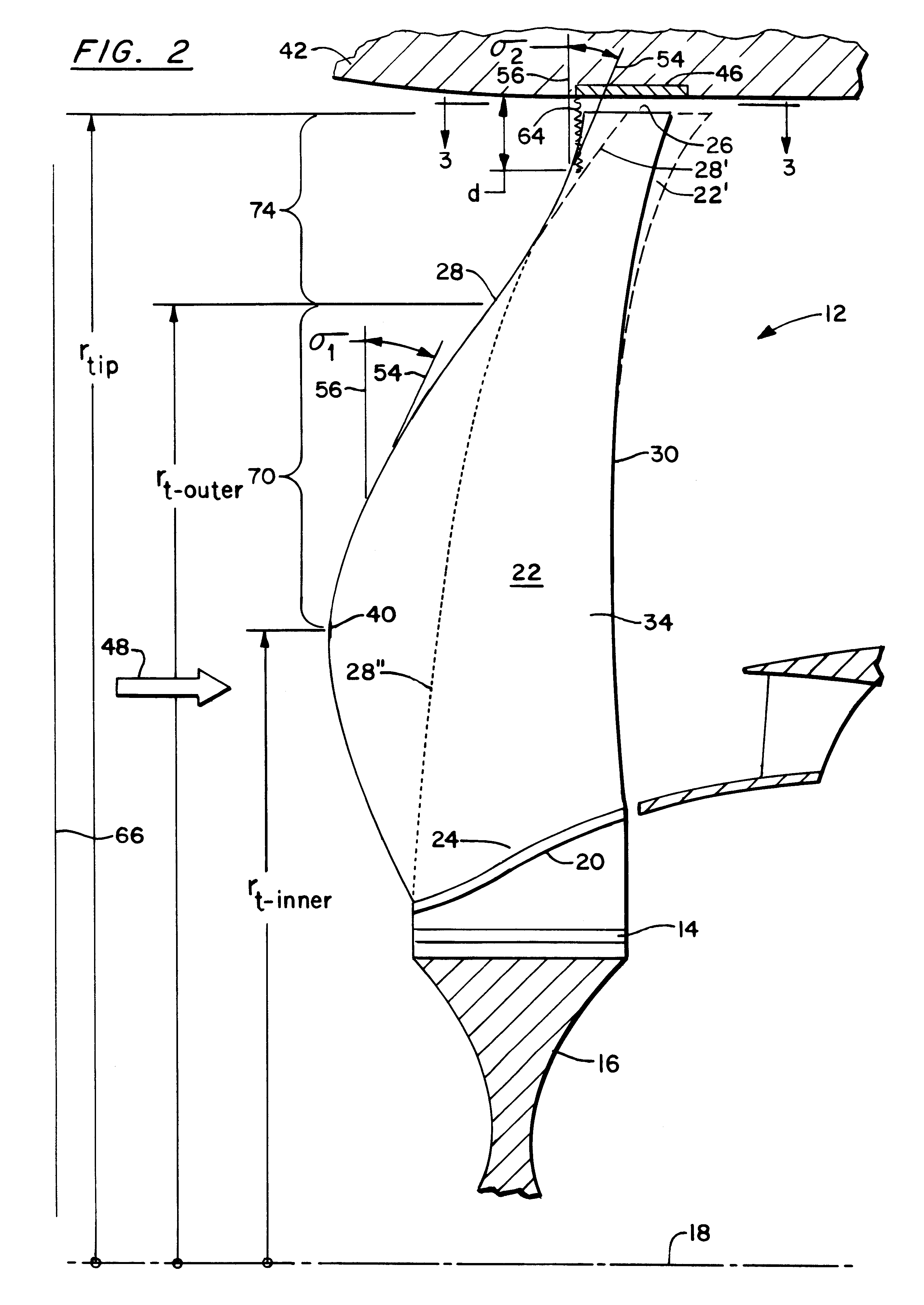

Referring to FIGS. 1-3, the forward end of a gas turbine engine includes a fan section 10 having a cascade of fan blades 12. Each blade has an attachment 14 for attaching the blade to a disk or hub 16 which is rotatable about a longitudinally extending rotational axis 18. Each blade also has a circumferentially extending platform 20 radially outward of the attachment. When installed in an engine, the platforms of neighboring blades in the cascade abut each other to form the cascade's inner flowpath boundary. An airfoil 22 extending radially outward from each platform has a root 24, a tip 26, a leading edge 28, a trailing edge 30, a pressure surface 32 and a suction surface 34. The axially forwardmost extremity of the leading edge defines an inner transition point 40 at an inner transition radius r.sub.t -inner, radially inward of the tip. The blade cascade is circumscribed by a case 42 which forms the cascade's outer flowpath boundary. The case includes a rubstrip 46 which partially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com