System of cooking or heating food products with microwaves and hot oil

a technology of microwave and food products, which is applied in the field of system of cooking or heating food products with microwave and hot oil, can solve the problems of unsatisfactory results of frying alone, inability to achieve satisfactory results by frying alone, and inability to use microwave heating alone to achieve undesirable results, etc., to achieve crispy outer crust (wrapper) or outer skin, rapid cooking and/or heating time, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

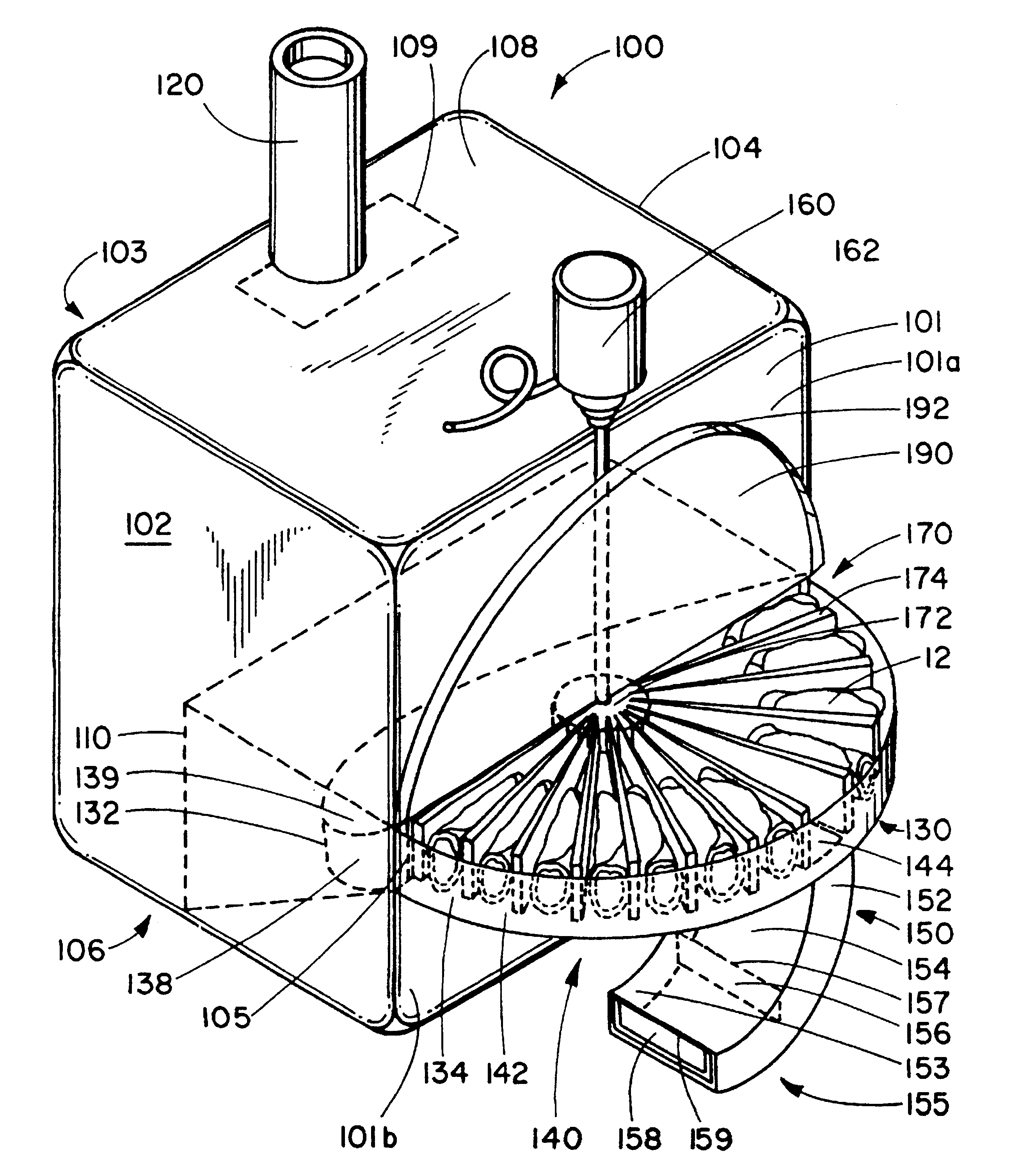

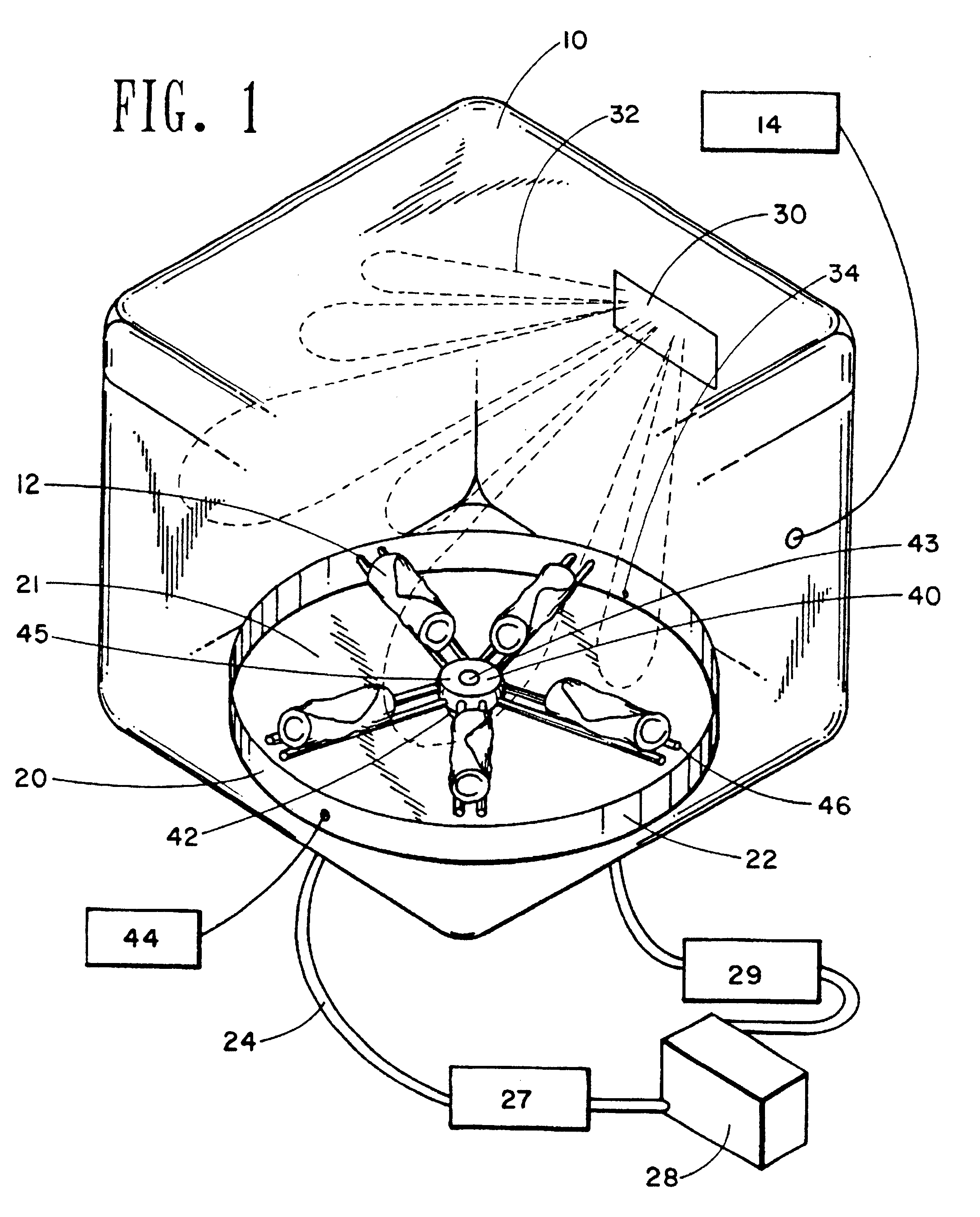

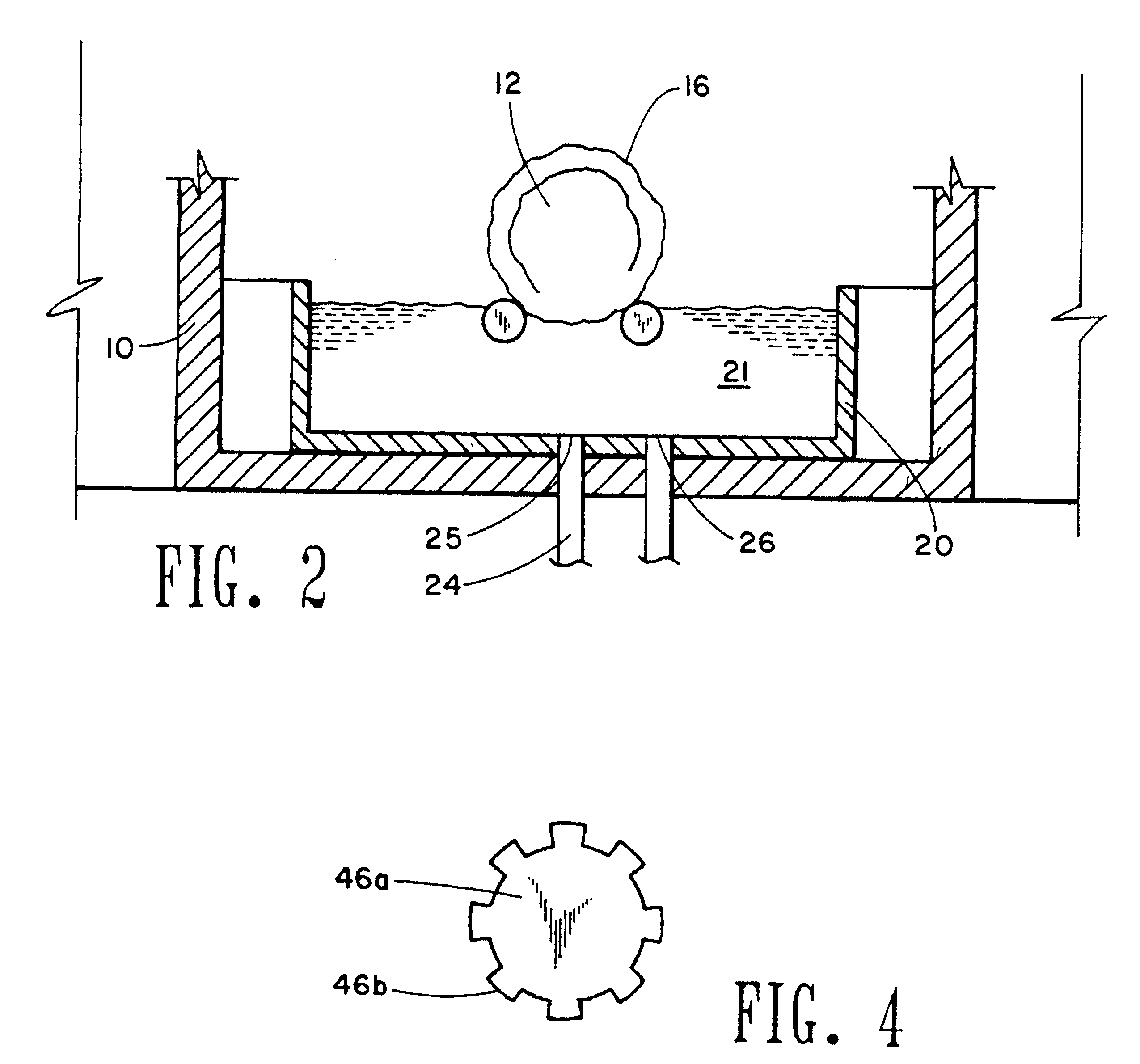

Referring to FIGS. 1 and 2, the system of the present invention generally includes an oven body 10, a hot oil system 20 containing hot oil 21, and a microwave source / receiver 30. The embodiment of the invention may include a rotating tree 40 for moving the food product 12 through the heating medium (oil) while turning the product about its core axis.

The food product 12 is cooked and / or heated in the oven body (or heating chamber) 10 which normally includes a door (not shown). Prior to cooking and / or heating, the food product 12 comprises a raw or a pre-cooked product which may be frozen, refrigerated or at room temperature. The food product generally requires frying, which includes products such as a french fry, a dough-based product such as a donut, or a food product having an inner filling enclosed in an outer shell such as an egg roll shown in FIG. 2 with the outer wrapper 16. Other food products represented by 12 may include similar products such as pizza rolls, spinach rolls, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com