Coffee and tea brewing apparatus and system

a coffee and tea brewing apparatus and technology of a system, applied in the field of brewing equipment and systems, can solve the problems of unsatisfactory coffee taste, unsatisfactory coffee taste, and long brewing time, and achieve the effect of superior coffee taste and constant brewing tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

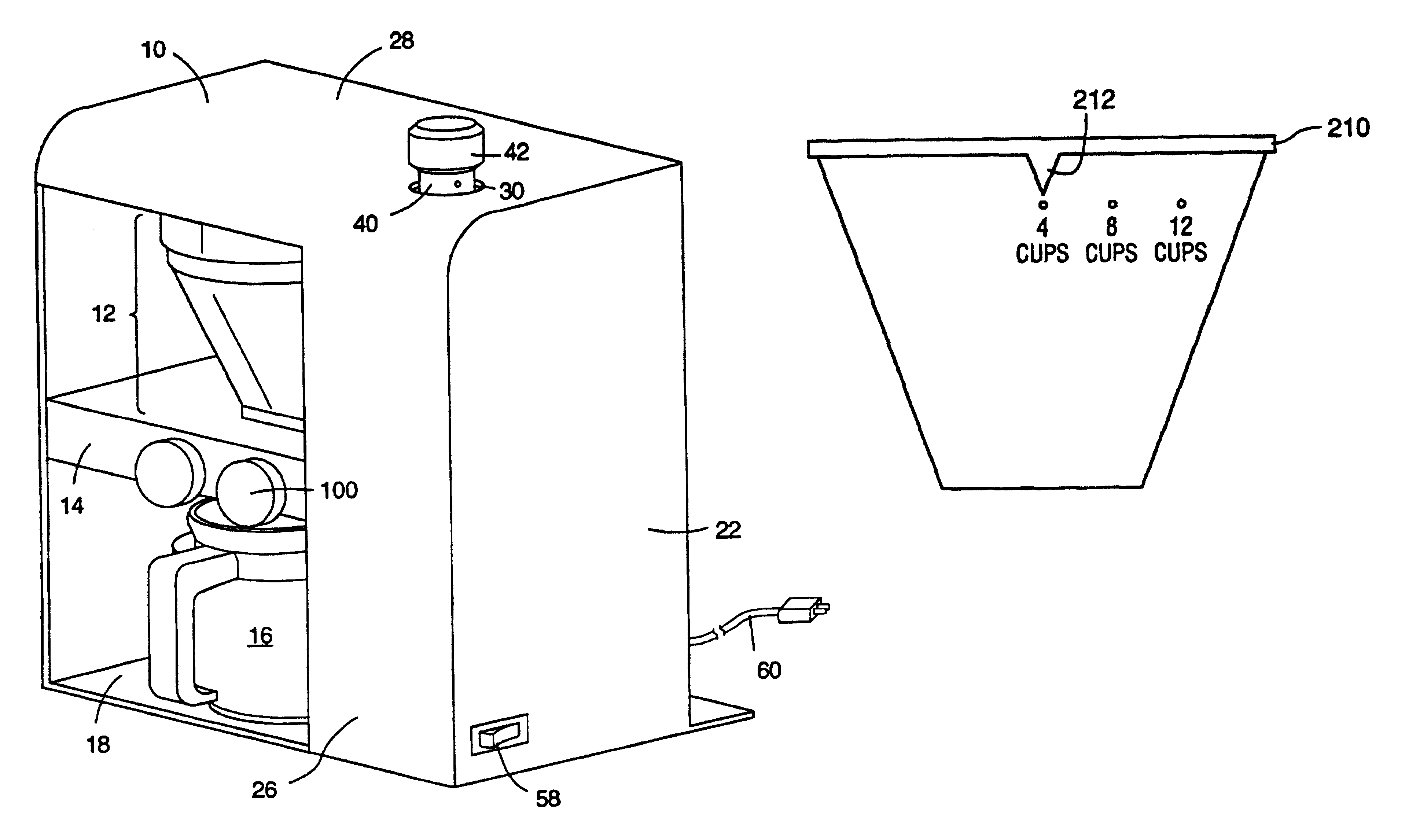

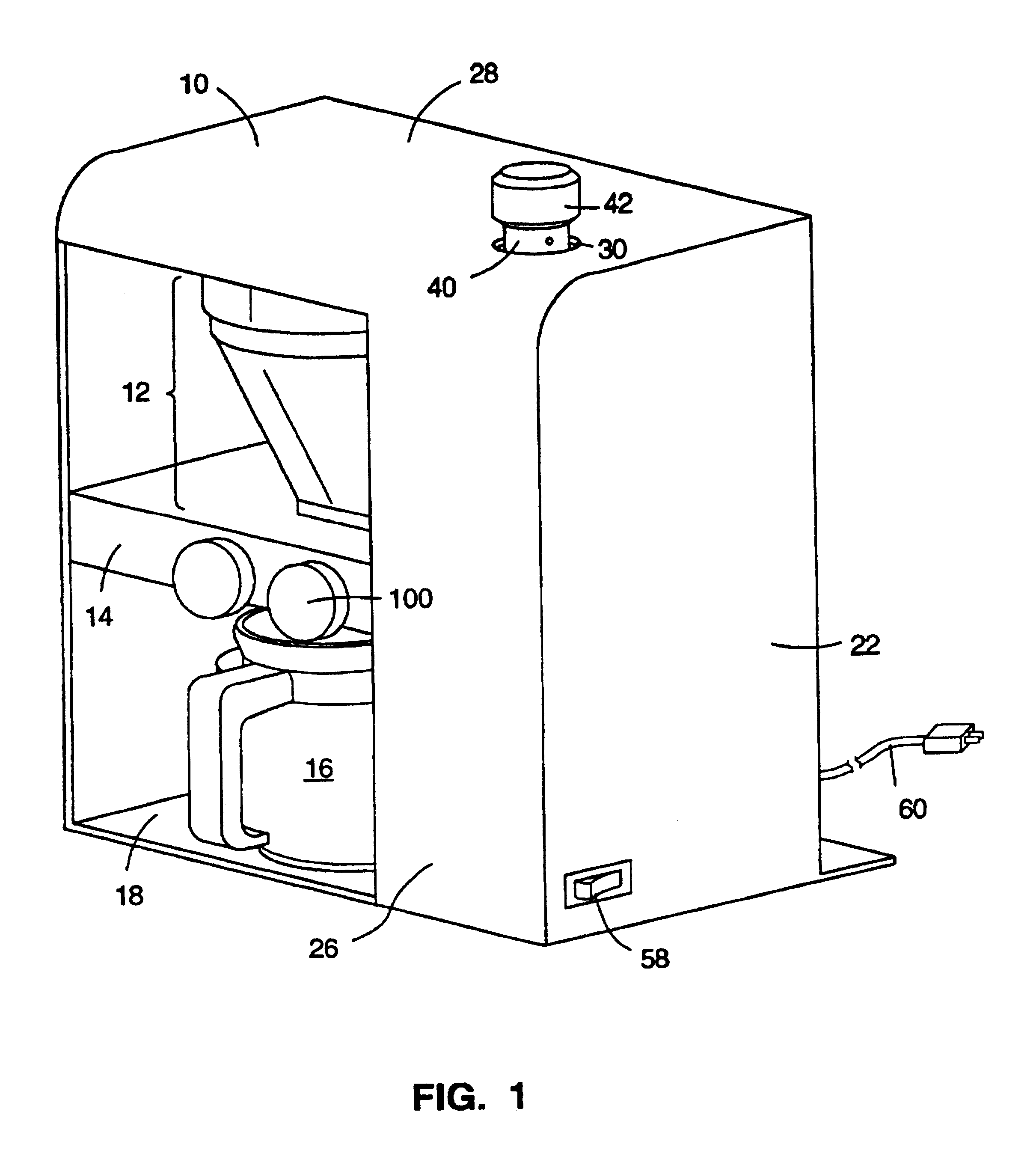

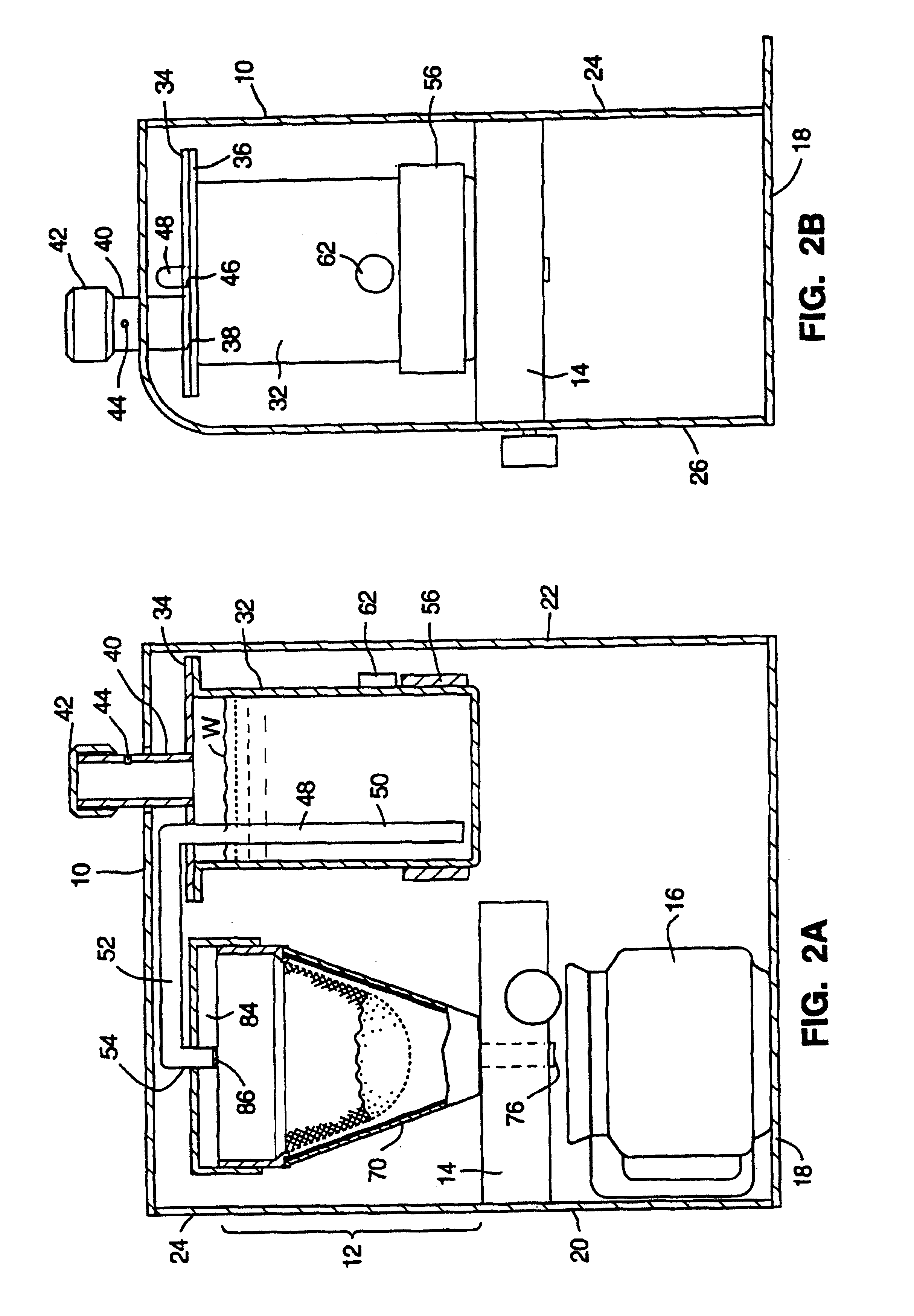

Image

Examples

third embodiment

a control valve assembly 98c is shown in FIGS. 10A and 10B. This control valve assembly 98c includes a rod 102c extending into a threaded bore 92c formed in the valve body 14c. At one end of the rod 102c is a control knob 100c which is located at the front 94c of the valve body 14c. The other end of the rod 102c is in contact with the silicone tube 76 extending from cone 70 (see FIG. 4C, or tubing 376 from cone 370, FIG. 6A), which extends through a substantially rectangular opening 88c in the valve body 14c. By rotating the control knob 100c in the manner described above, the rod 102c is made to constrict (FIG. 10A) or release (FIG. 10B) the silicone tubing 76.

fourth embodiment

a valve body 14d is shown in FIGS. 11A and 11B. As with the other valve body configurations, the valve body 14d includes an opening 88d through which the silicone tubing 76 from cone 70 (see FIG. 4C) at least partially extends. A stepper motor 130 is mounted to back wall 24d of the coffee maker housing 10 (housing shown in FIGS. 1-2B). A plunger 132 having a beveled end extends from the stepper motor 130 and through an opening in the back wall 24c. The plunger 132 and stepper motor 130 are coupled to one another such that activation of the stepper motor 130 moves the plunger 132 incrementally towards or away from the tube 76 in response to application of a drive signal to the stepper motor 130.

FIG. 12 is a simplified schematic diagram illustrating a coffee brewing system embodying the fourth embodiment of the valve body 14d. A user interface device 134 (which may be a keypad, dial, or any other form of input device) is provided which enables a user to input volume information repres...

sixth embodiment

a control valve is shown in FIG. 18. In this embodiment, which is particularly useful for brewing teas, the heated water is held in the brewing chamber for the duration of the desired brew time, and then quickly released into an underlying container at the end of the brew time.

Referring to FIG. 18, tube 76 which extends from cone 70 is equipped with a sensor 114 for detecting the presence of heated water in the brewing chamber 14. The sensor 114 can be one of several types of generally known sensors capable of sensing liquid, an increase in mass, or an increase in temperature. For example, the sensor 114 may be a thermocouple which detects an increase in temperature in the tube 76. Alternatively, the sensor 114 may be a conductivity probe which senses the presence of water inside the tube, since water is more highly conductive than air.

The opening of the tube 76 is covered by a valve door 116. Valve door 116 is pivotable about a pin 118 between an opened condition (shown in dashed l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com