Visible light and infra-red cooking apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

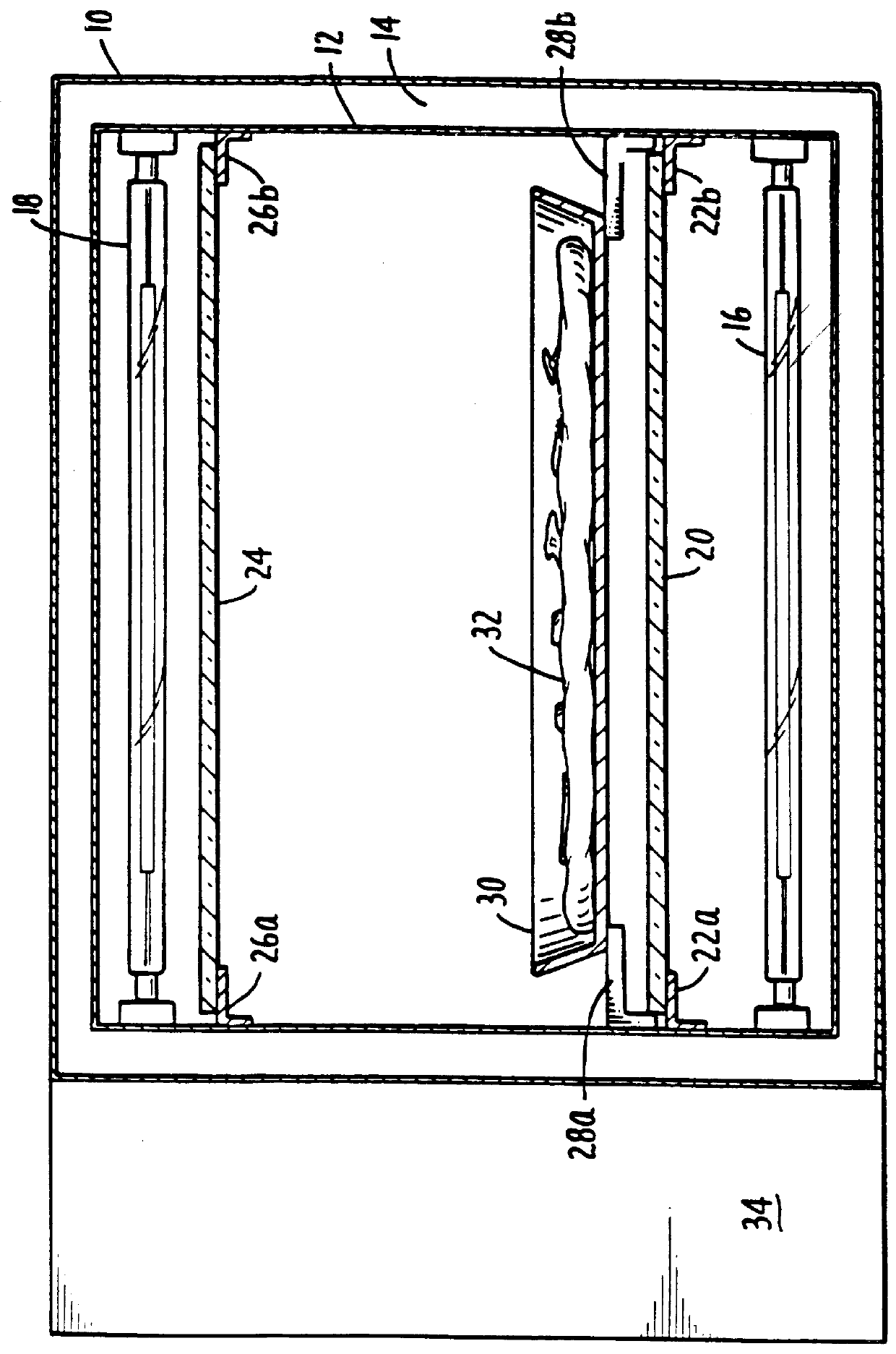

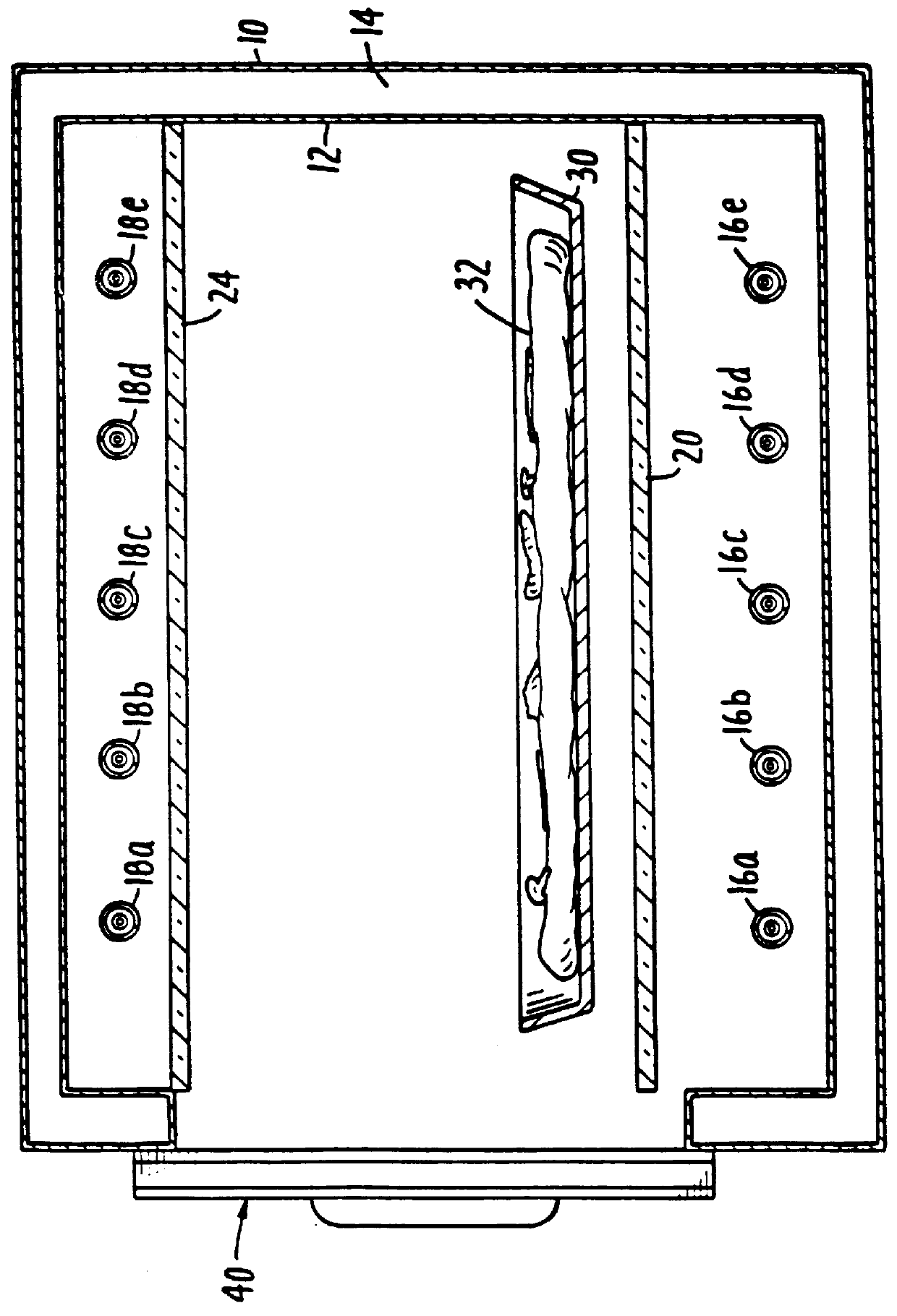

FIG. 1 is a front cross section of the preferred embodiment of the present invention. The oven in FIG. 1 includes an outer enclosure 10. The enclosure has an inner wall 12 coupled to the outer wall 10. Ordinarily, an insulating layer 14 is formed between the outer enclosure 10 and the inner wall 12. Because of the inherent speed of the cooking cycle, the insulating layer 14 may be a layer of air.

The energy for cooking is supplied by the lower radiation heating lamps 16 and the upper radiation heating lamps 18. These lamps are generally any of the quartz body, tungsten-halogen lamps commercially available, e.g., 1.5 KW 208 V quartz-halogen lamps. The oven according to the preferred embodiment utilizes ten such lamps and cooks with an average of 10% of the energy in the visible light portion of the spectrum, which is significant. The inner surface of the inner wall 12 is preferably a highly polished, poorly absorptive surface, so that it appears to be very reflective to the wide spect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com