Integrated motor/gear pump

a technology of integrated motors and gear pumps, applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of unbalanced axial, restricted space, and foregoing gear types, and achieve the effect of reducing nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

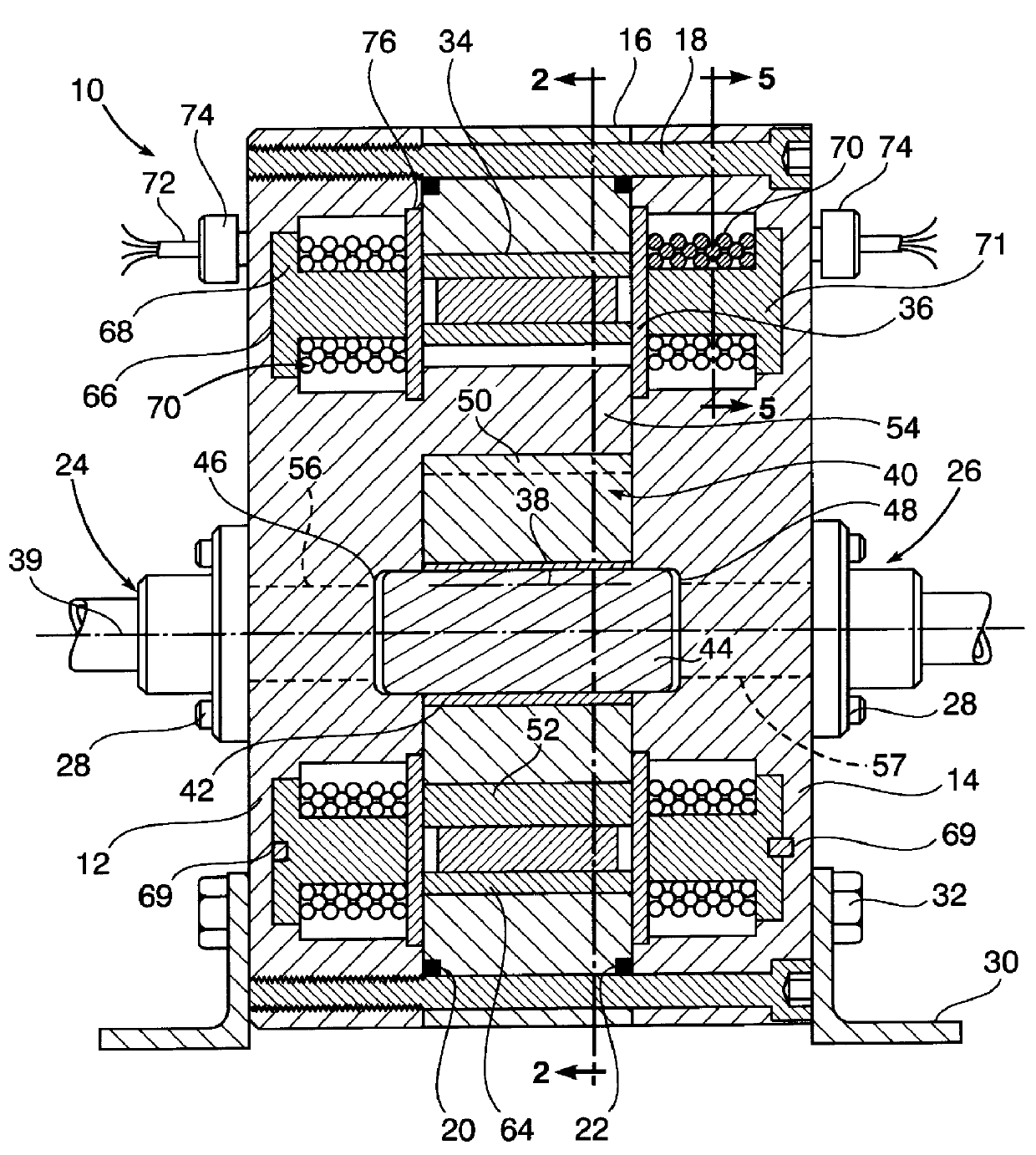

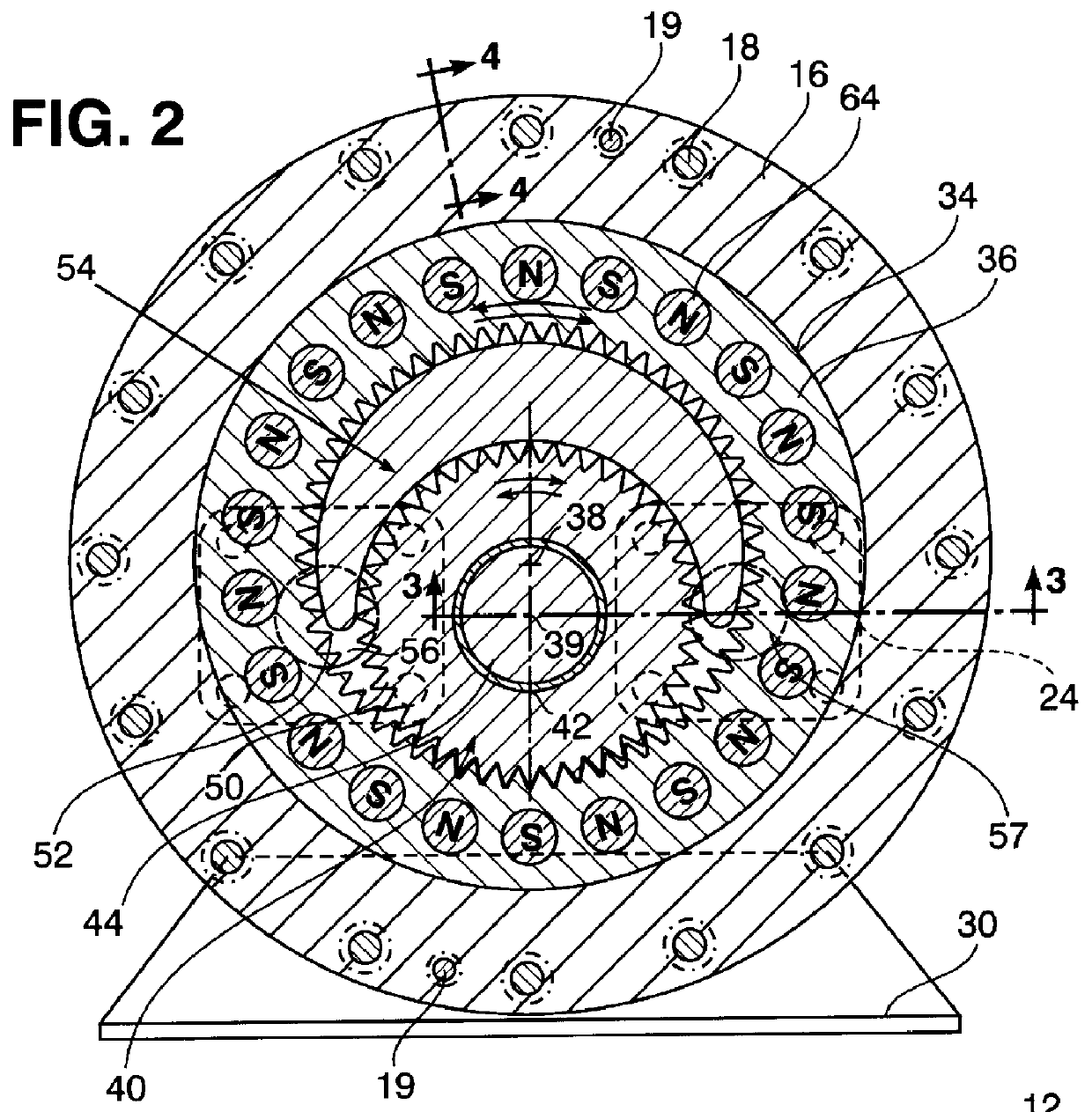

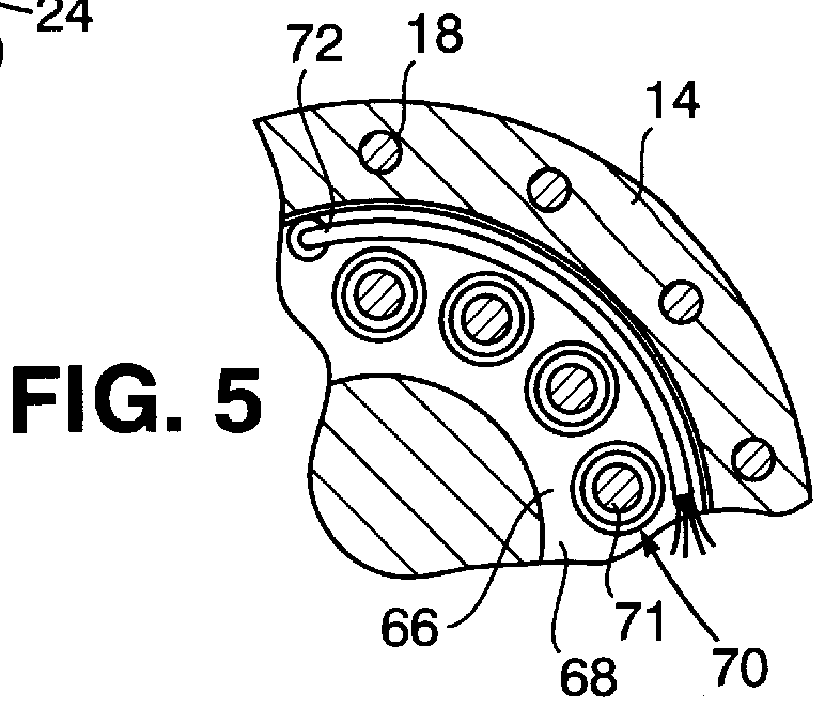

Referring now to the drawing in detail, FIG. 1 illustrates in side section an integrated motor / pump unit generally referred to by reference numeral 10 having a housing formed by a pair of flat circular side plates 12 and 14 axially separated by a circular bearing cylinder 16 to which the plates are secured after being radially aligned therewith. A plurality of circumferentially spaced fastener bolts 18 extend from the plate 14 through the cylinder 16 and are threadedly received within the plate 12 to interconnect the plates and cylinder, while precise radial alignment is achieved by two dowels 19 as shown in FIG. 2 extending parallel to the bolts 18 through the plates and cylinder. A pair of annular seals 20 and 22 are respectively carried by the cylinder 16 on opposite axially sides thereof for contact with the side plates 12 and 14 in close radially spaced relation to the bolts 18 so as to seal an internal pump chamber within the cylinder 16 between the plates 12 and 14. Inlet and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com