Control apparatus for vehicle

a technology for controlling apparatus and vehicle, applied in mechanical apparatus, transportation and packaging, gearing, etc., can solve problems such as inability to establish a desired gear stage, uplocks may occur, etc., to achieve effective external force, increase the probability of avoiding uplocks, and increase the rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Hereinafter, embodiments of the invention will be described in detail with reference to the accompanying drawings.

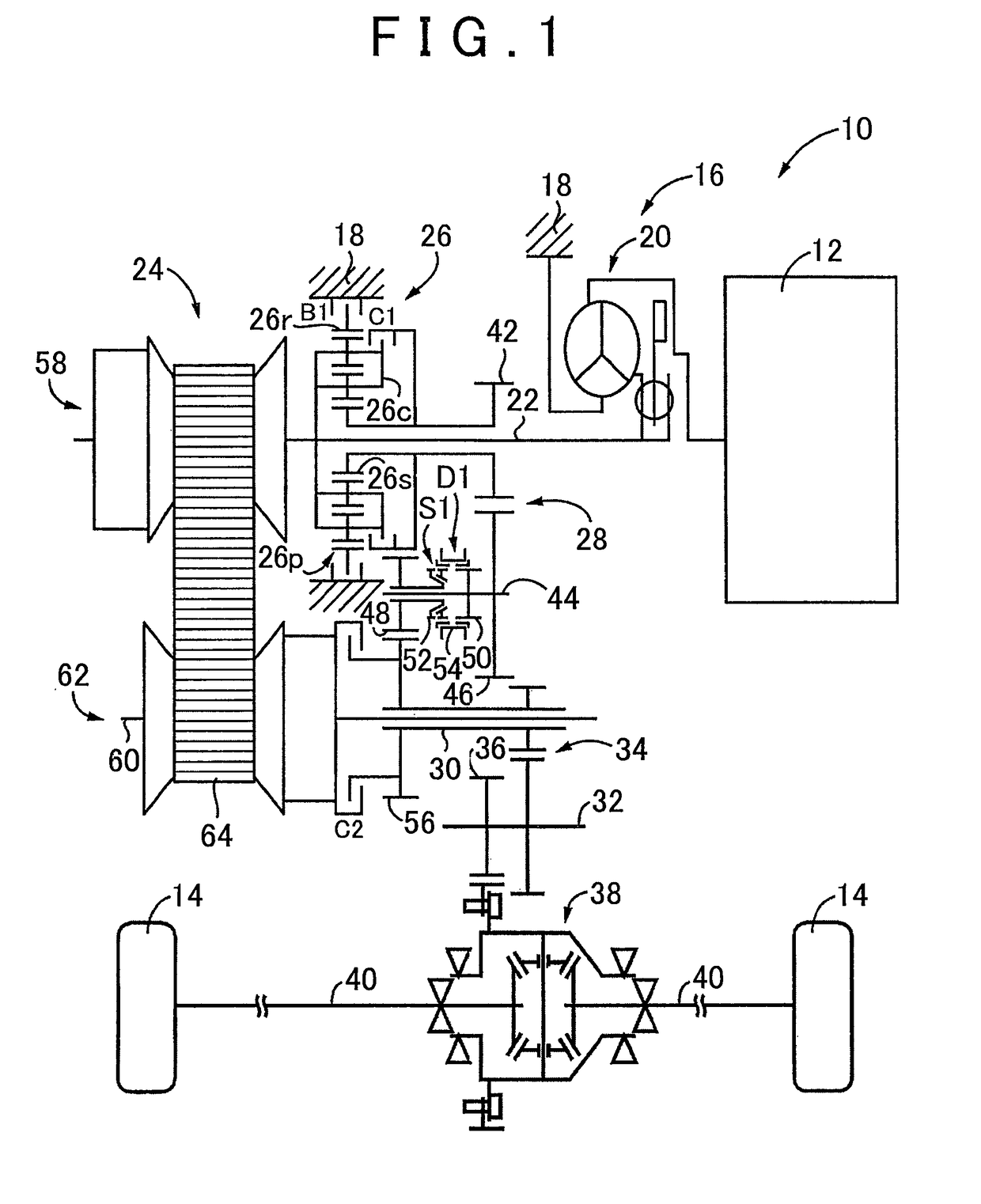

[0023]FIG. 1 is a view that illustrates the schematic configuration of a vehicle 10 to which the invention (first embodiment) is applied. As shown in FIG. 1, the vehicle 10 includes an engine 12, drive wheels 14 and a power transmission system 16. The engine 12 functions as a driving force source for propelling the vehicle 10. The power transmission system 16 is provided between the engine 12 and the drive wheels 14. The power transmission system 16 includes a known torque converter 20, an input shaft 22, a known belt-type continuously variable transmission 24 (hereinafter, referred to as continuously variable transmission 24), a forward / reverse switching device 26, a gear mechanism 28, an output shaft 30, a counter shaft 32, a reduction gear unit 34, a differential gear 38, a pair of axles 40, and the like. The torque converter 20 serves as a fluid transmission de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com