Supply module for an automated analyzer

an automated analyzer and module technology, applied in the field of analytical instruments in the field of in-vitro diagnostics, can solve the problems of high consumable consumption of analytical instruments in a relatively short period of time, high cost of in-vitro diagnostics, and high labor intensity and time consumption of above-described separate loading, so as to reduce down-time and user intervention, facilitate workflow, and increase analytical throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0095]In the following, examples are provided in order to display certain embodiments and to exemplify the subject matter described herein. It is to be understood that also other embodiments are comprised by the scope of the subject matter, as known by the person skilled in the art.

Detailed Description of the Figure

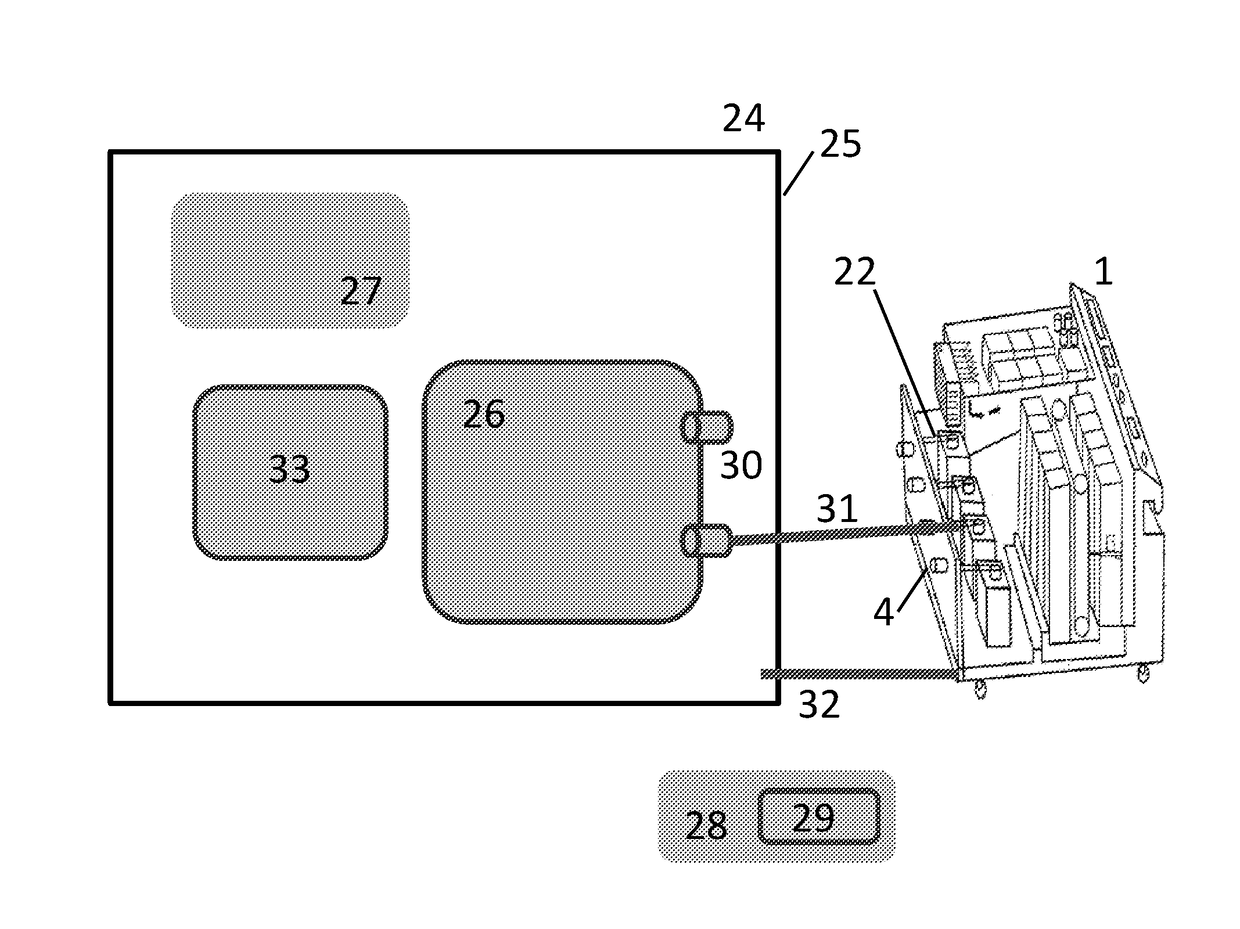

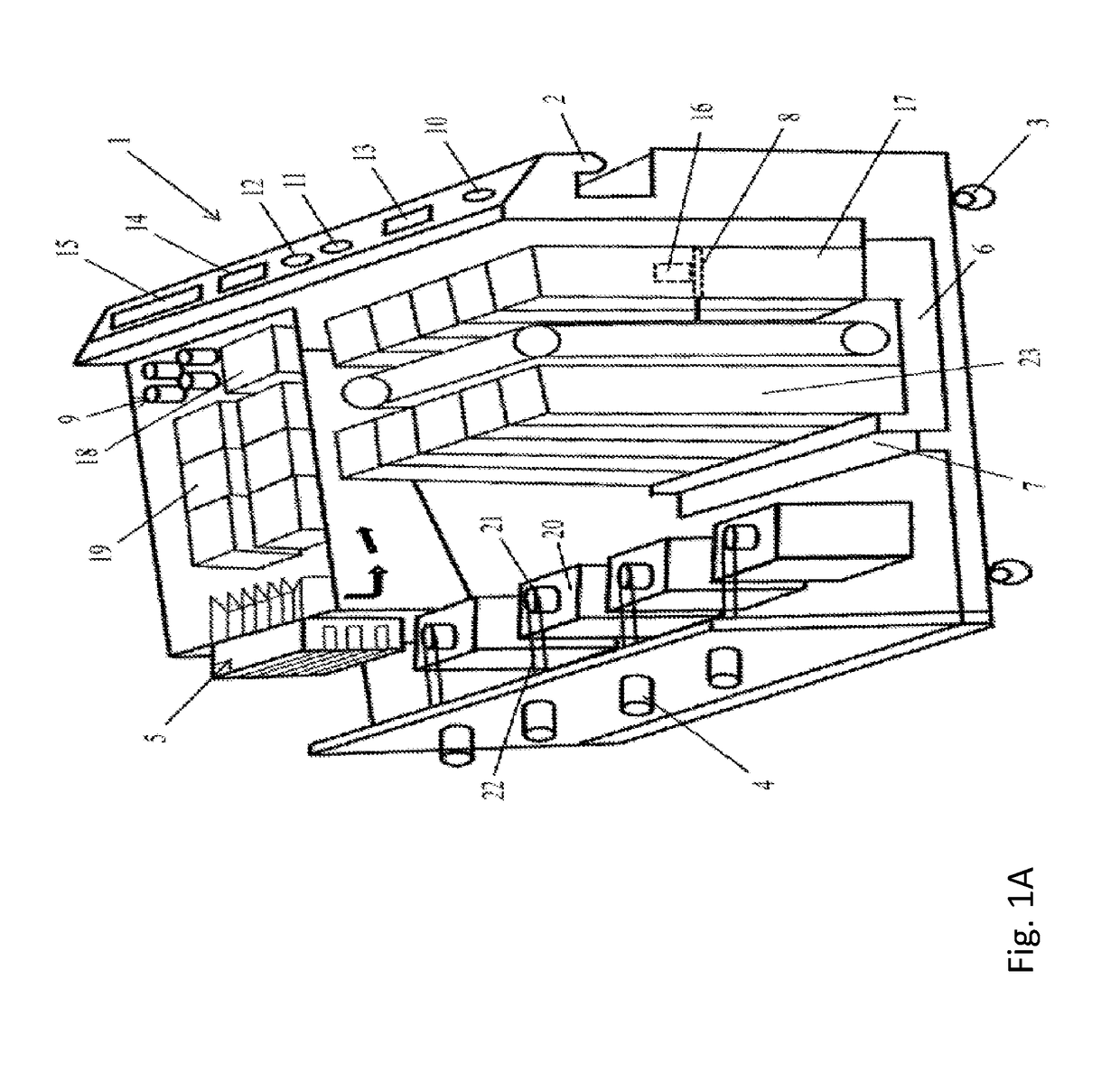

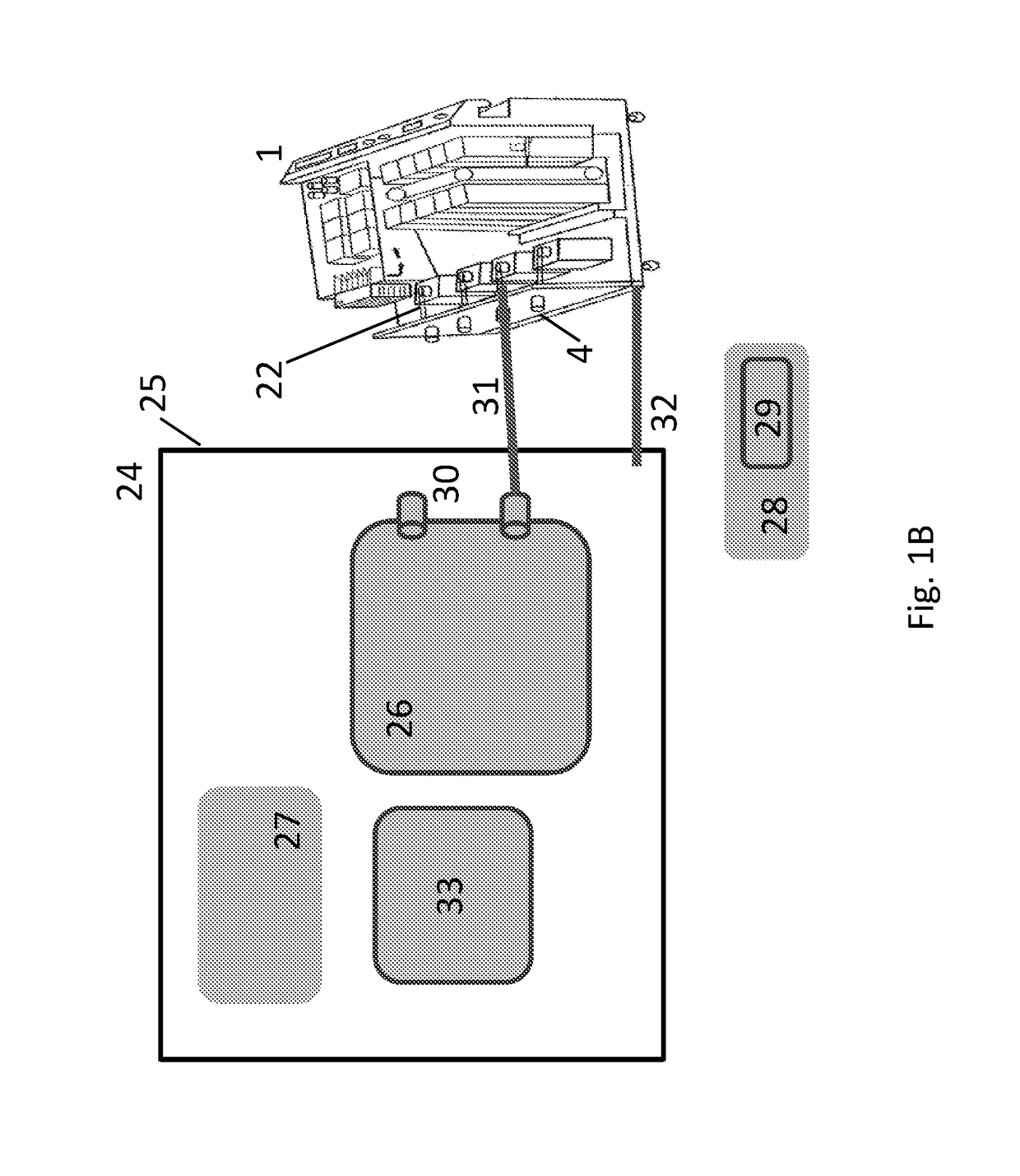

[0096]The supply module (1) depicted herein comprises elements of a drawer, such as a handle (2) for manually pulling the supply module (1) out of the analyzer or pushing it therein. The supply module further includes wheels (3) providing it with characteristics of a trolley. The wheels (3) may be passive and of purely mechanical nature, i.e. they may enable rolling the trolley by means of human force. In other embodiments, the wheels (3) may be connected to an actuator permitting movement of the supply module (1) without applying external force. The wheels (3) may be directionally fixed, or they may be rotatable around a rotational axis in order to facilitate directional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| flexibility | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com